Projects

Minimum Design Metal Temperature (MDMT) Assessment of Heat Exchangers

Industry

Oil & Gas

Services

Piping, Pressure Vessels

Location

UK

The challenge

At lower temperatures, many materials, especially steels, transition from ductile to brittle, leading to sudden and unexpected fractures that pose significant safety risks.

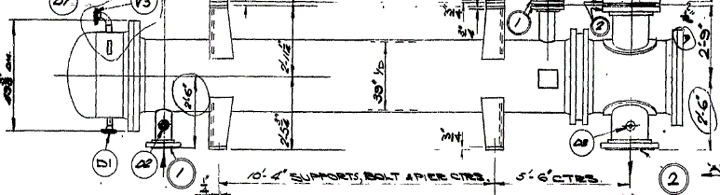

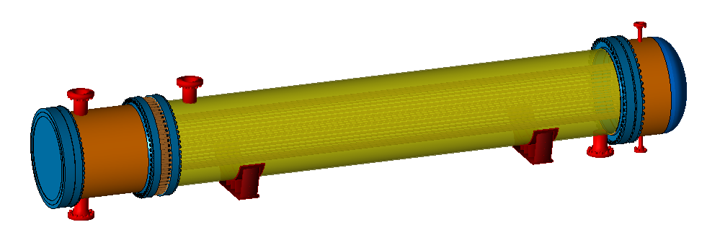

DOCAN was contracted by our client to calculate Minimum Design Metal Temperature (MDMT) aimed at guaranteeing the resilience of heat exchangers against brittle fracture in hydrostatic testing.

The DOCAN solution

DOCAN processed MDMT assessments including:

- An initial detailed calculation aligned with ASME code directives for a series of 18 heat exchanger units, which established an MDMT baseline for each unit, ensuring they met the minimum safety thresholds.

- Subsequent assessment concentrates on units with higher MDMTs to reduce the testing temperatures. This reduction could decrease the costs and complexities associated with the testing phase. Software PV Elite was used to assist the calculation.

The outcome

The assessment not only established a basic safe temperature for hydrostatic testing of heat exchangers but also sought a solution that allows for more moderate testing environments without compromising the units’ resistance to brittle fracture.