Software

Our core tools

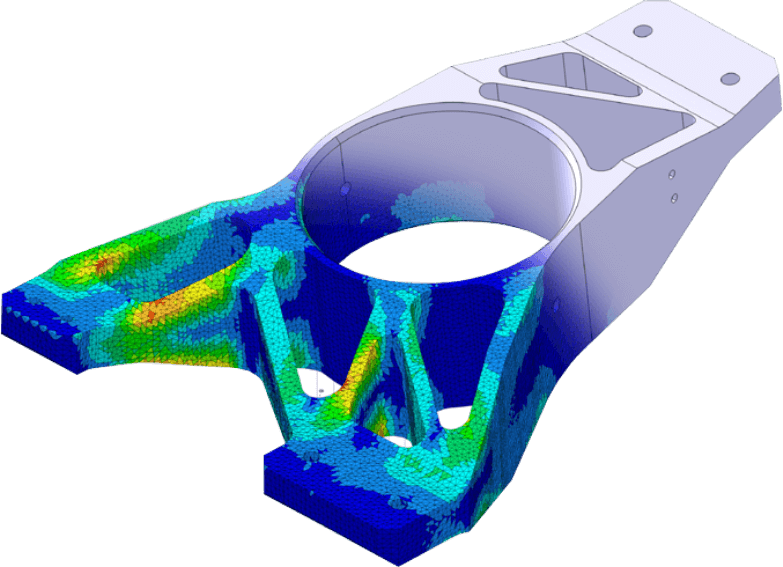

DOCAN’s consultancy services rely on the skills and expertise of our team of engineers, designers and consultants, and the use of state-of-the-art engineering software.

We have many years of experience across all major engineering disciplines, and we always use the right tools for the job to bring our clients cutting-edge solutions.

We have a can-do attitude – with the right technology, experience and attitude, we believe nearly anything is possible. Our core tools showcase some of the leading software we integrate into our services.