Consultancy

Rotating Equipment

At DOCAN, our consultancy team brings expertise in the design, analysis, and optimisation of complex rotating machinery to help clients improve performance, reliability, and efficiency.

Whether it’s a compressor in a high-integrity process system, a gearbox on a military vehicle, or a turbine in a power plant, we provide the insight and engineering support needed to make sure critical equipment works first time, every time.

Our rotating equipment design & engineering expertise

We work across a wide range of rotating equipment, from compressors and turbines to pumps, gearboxes, and engines. Each system has its own challenges – whether it’s vibration, efficiency, or durability – and we use advanced simulation and engineering expertise to solve them.

-

Compressors

Compressors are vital for moving gases in defence, aerospace, and industrial systems. We help clients analyse and optimise compressor performance, focusing on efficiency, vibration, thermal effects, and durability. Our engineers can model fluid flow (CFD) and mechanical stresses (FEA) to ensure robust designs that perform under demanding conditions. -

Gas Turbines

Gas turbines are central to both aerospace propulsion and power generation. We provide structural and thermal analysis to ensure turbine blades, casings, and rotors can withstand extreme temperatures, pressures, and vibration loads. Our expertise helps extend turbine life and optimise efficiency. -

Pumps

Pumps are often exposed to variable flow rates and harsh environments. We help clients with design, performance validation, and failure investigations, covering centrifugal, positive displacement, and specialised pump systems. CFD and FEA are used to optimise flow paths, reduce cavitation, and improve mechanical integrity. -

Steam Turbines

Steam turbines demand robust engineering to cope with high pressures and temperatures. Our consultancy services include stress analysis, vibration modelling, and thermal assessment to improve reliability and operational performance across both industrial and defence applications. -

Gearboxes

Gearboxes transfer power in systems ranging from aircraft engines to naval propulsion. We support clients with structural and fatigue analysis, vibration assessment, and optimisation of gear geometry. Our work helps reduce wear, prevent unexpected failures, and extend service life. -

Centrifugal Pumps

Centrifugal pumps are widely used across industries but are often prone to vibration and efficiency losses. We provide simulation and diagnostic services to optimise pump impellers, minimise cavitation, and improve flow performance. -

Reciprocating Engines / Heat Engines

Reciprocating engines and heat engines are subject to dynamic loading, vibration, and thermal stresses. We support clients with durability analysis, vibration modelling, and redesign services to enhance reliability and efficiency. -

Blowers

Blowers play a key role in ventilation, cooling, and process systems. We help optimise design for efficiency, noise reduction, and vibration control, ensuring long-term, reliable performance. -

Shafts, Bearings and Seals

In any rotating equipment, the shaft plays a critical role in transferring loads and motion from one part of the machine to another. Shafts must be designed to cope with stresses, vibration, and dynamic behaviour to ensure long-term performance.

Supporting the shaft are the bearings, which may be rolling element, hydrostatic, magnetic, or other specialist types depending on the application, speed, and load requirements. Selecting the right bearing type and size is essential not just for life and reliability, but also for vibration control and overall system stability.

Seals are equally important – ensuring fluids stay contained and that the internal environment of the machine remains protected. Together, shaft, bearing, and seal design are integral to reliable rotating machinery, and we apply advanced simulation and design tools to get this balance right.

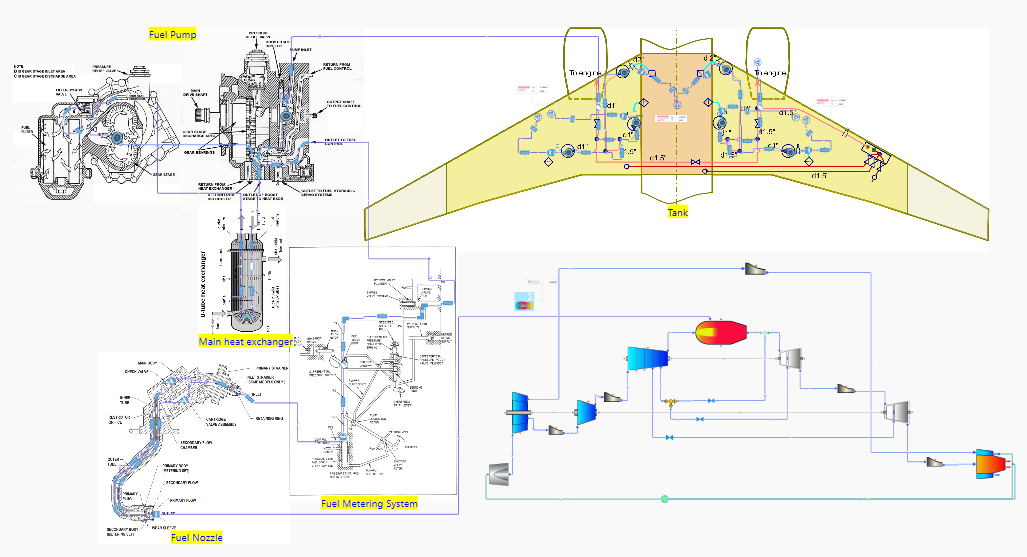

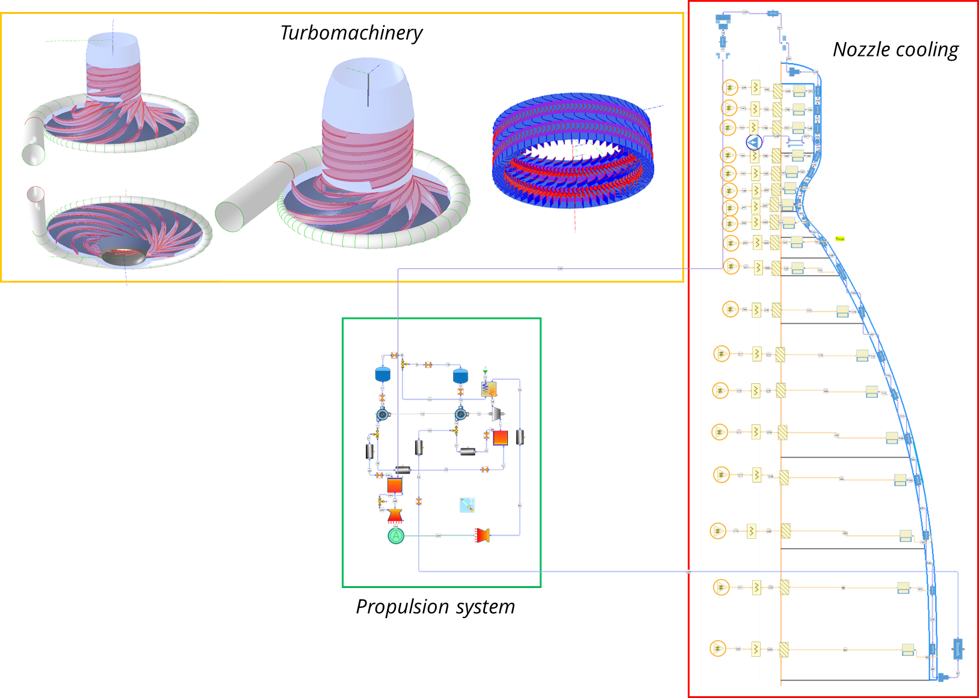

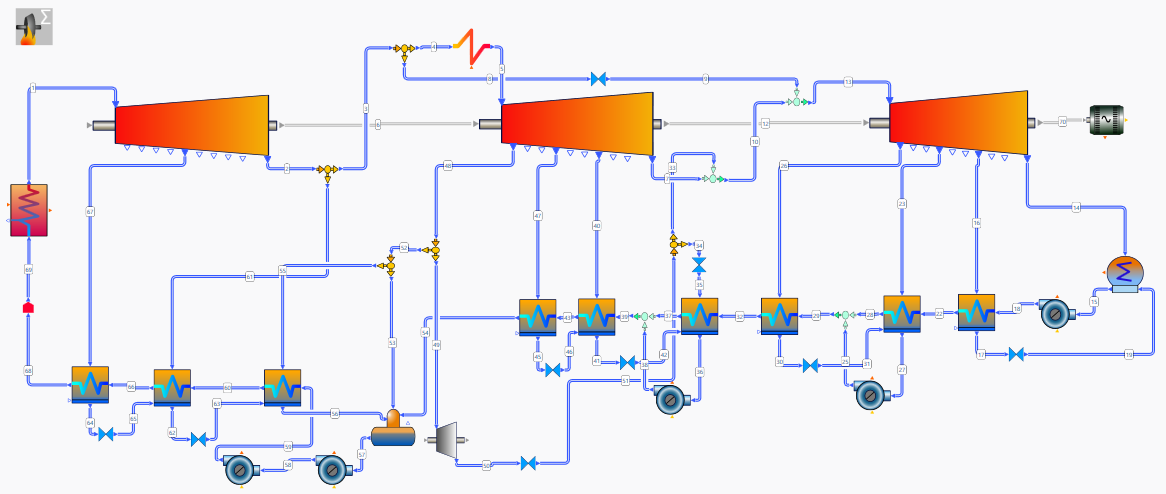

AxStream for rotating equipment design

As a Registered Partner with SoftInWay, DOCAN uses the AxSTREAM® suite to support rotating equipment and turbomachinery projects. This industry-leading software allows us to design, simulate, and optimise compressors, turbines, pumps, and engines with speed and accuracy.

By combining AxSTREAM’s powerful capabilities — from generative design and 3D analysis to rotor dynamics and performance prediction – with our consultancy expertise, we help clients reduce development time, cut costs, and achieve reliable, efficient designs.

Why choose DOCAN as your rotating equipment consultancy?

At DOCAN, we bring expertise across multiple industries, including defence, aerospace, energy, and manufacturing. This experience means we understand the unique challenges of rotating equipment in different environments, from high-integrity aerospace systems to industrial power plants.

We also make use of advanced simulation tools such as CFD, FEA, and multiphysics analysis. These allow us to accurately predict how equipment will perform, identify weak points, and design solutions that improve reliability and efficiency.

Beyond design, we have extensive experience solving real-world problems, whether it’s concept development, performance optimisation, or failure investigations. Our approach means we work closely with clients to provide practical, data-driven solutions that fit their needs. With a proven track record, we’ve helped clients reduce downtime, extend equipment life, and improve performance across a wide range of rotating equipment applications.