Consultancy

Engineering Design &

Simulation Training Services

Our engineers are encouraged to approach problems from different angles, and also to explore new methods and technologies where these could deliver benefits to our clients.

Combined consultancy &

tech. transfer projects

In addition to offering our engineering consultancy services, we can combine consultancy with training to transfer the necessary skills into your business so over time, allowing you to undertake the work yourself, whilst also having DOCAN available for expert advice and guidance.

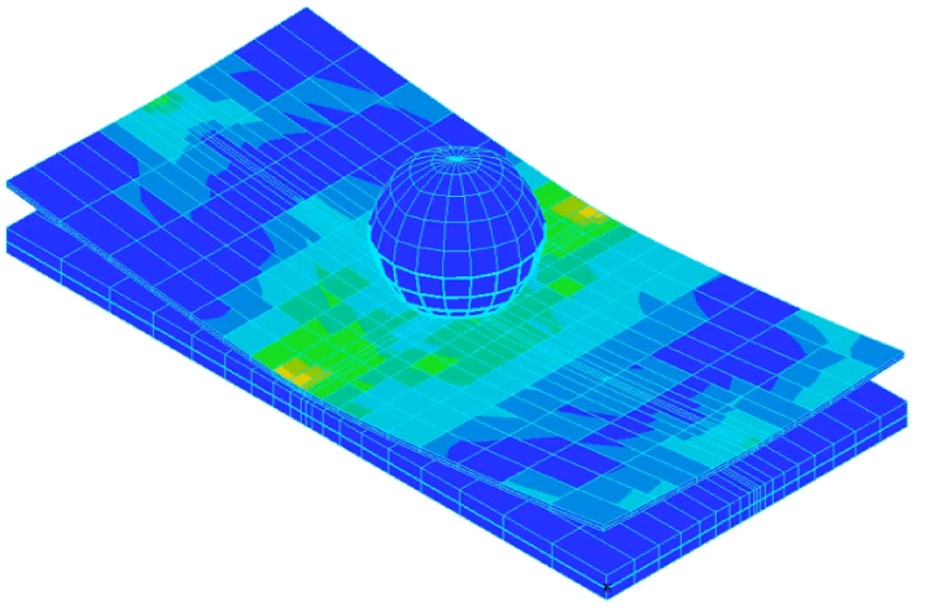

This is an example of how we work with one of our clients – an international electronics manufacturer who was investigating the impact performance of their products. We can provide software and theory training, we can build your basic calculations and models for you, and most importantly we can guide you on the best practices to provide a cost-efficient route to solving your engineering problems.

Engineering Design and

Simulation training services.

We can provide a range of software training services in many areas, such as CAE, FEA, and CFD.

We can also build custom training courses – you may want to combine FEA theory with a specific piece of software. This is no problem for us.

Our latest training courses

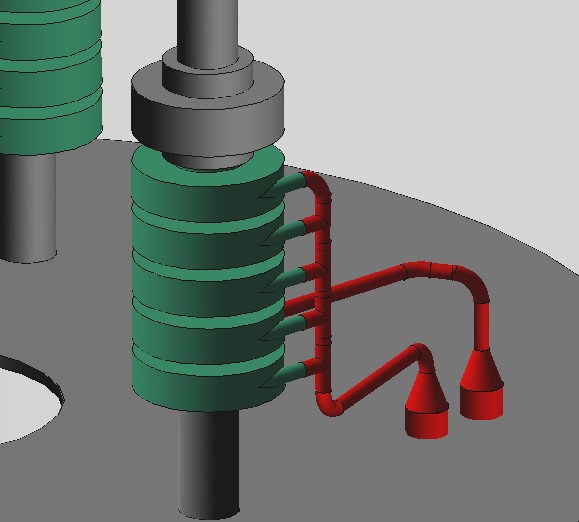

Piping Engineering & Pipe Stress Analysis

This course covers:

- Piping components, supports, layout principles, and failure modes

- Pipe specifications, wall thickness calculations, and mechanical design under pressure

- Loads and load cases: sustained, thermal, occasional, and dynamic

- Pipe stress analysis using CAESAR II, including hands-on modelling tutorials

- How to evaluate support loads, displacements, stress ranges, and system behaviour

- Typical challenges such as support lift-off, flange leakage, creep effects, and dynamic interaction with rotating equipment

This course runs until mid 2026 and dates are flexible. Learn more and sign up here.

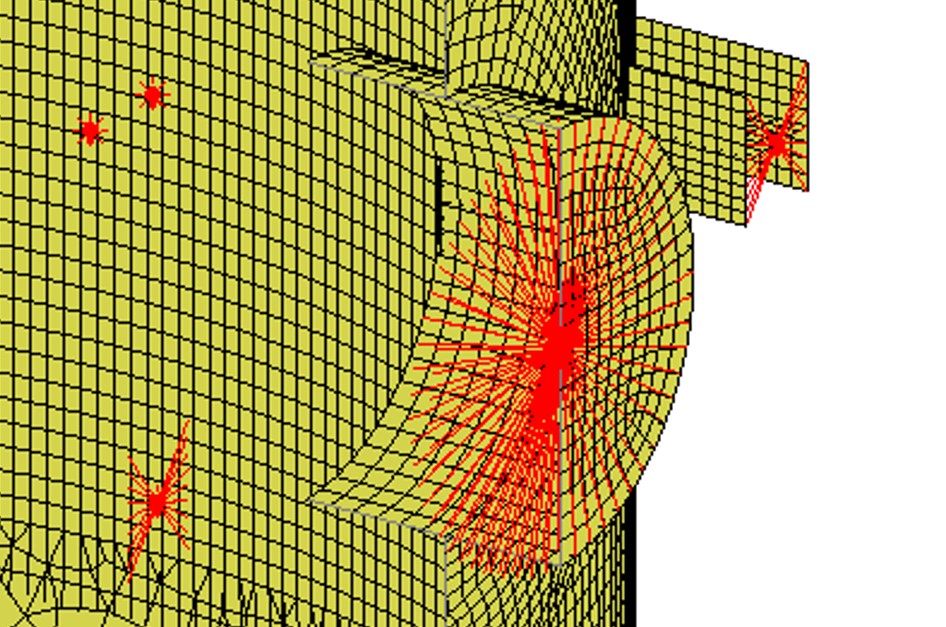

Science of Fitness For Service Assessment

This course covers:

- The evolution of FFS standards, including API 579-1/ASME FFS-1 and others

- Structural failure modes such as brittle fracture, metal loss, creep, fatigue, and hydrogen damage

- Key principles such as Remaining Strength Factor (RSF), Safety Factors, and MAWP

- Understanding assessment levels (L0–L3) and how to escalate appropriately

- Practical guidance on interpreting tmin, MSDs, and how to respond when standard limits are exceeded

This course runs until mid 2026 and dates are flexible. Learn more and sign up here.

Automation

From time to time DOCAN develop their own tools as part of internal R&D. One such toolkit is “DSET” – DOCAN Stress Engineering Tools. For others, we use a range of methods from Fortran and C to Python and Maple. These tools follow our ISO9001 approach and include a structured and open verification and QA process.