Projects

Structural Design and Analysis: Replacement Access Platform for a Tank

Industry

Manufacturing

Services

Civil & Structural Engineering, Stress Analysis

Location

UK

The challenge

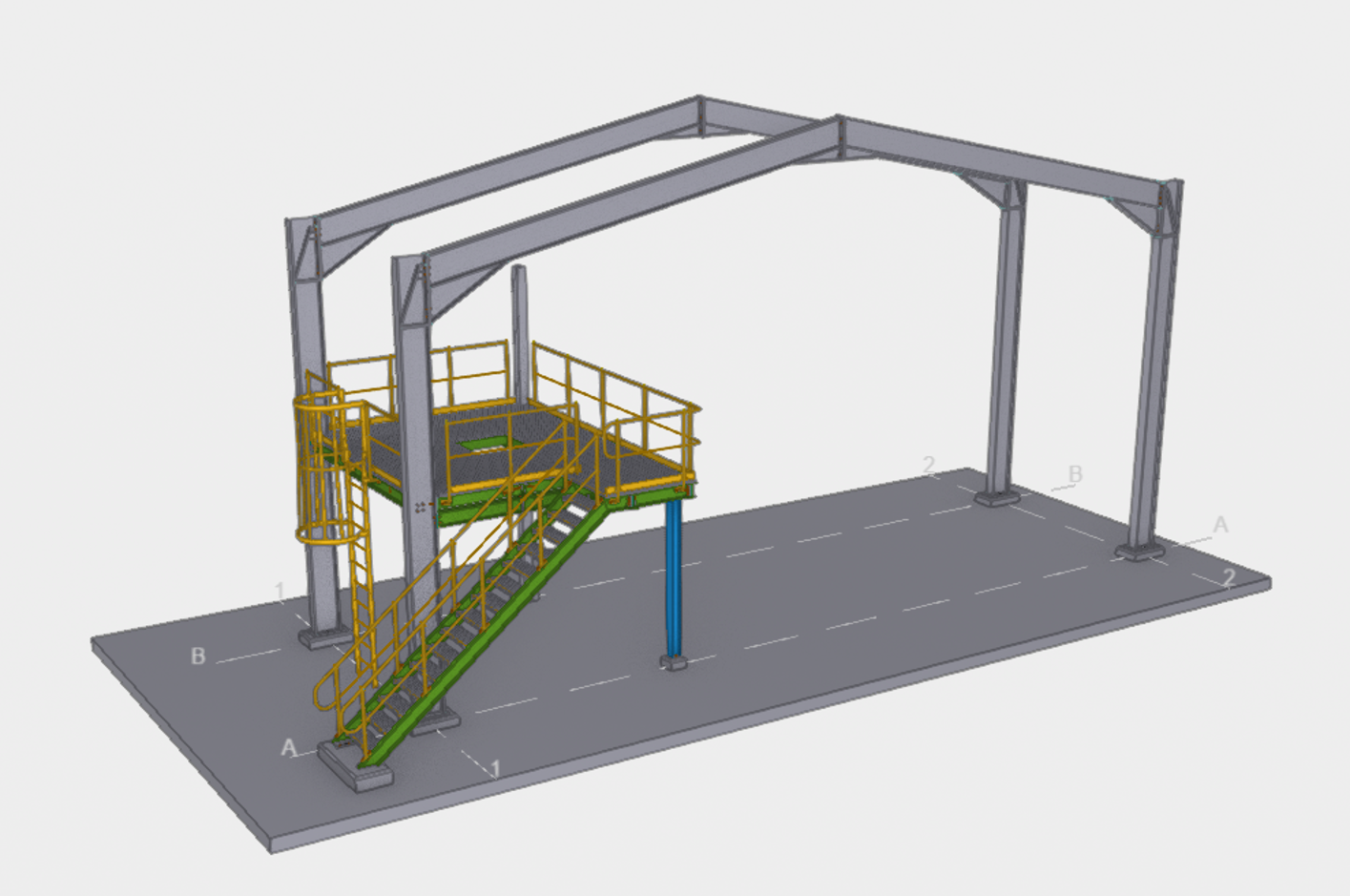

DOCAN were required to support our client in performing the structural design and analysis for the replacement access platform as part of ongoing maintenance across a plant at Stallingborough.

The DOCAN solution

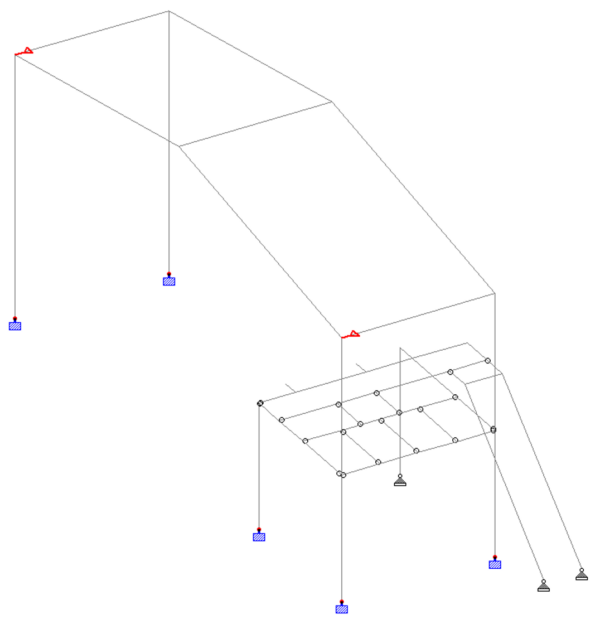

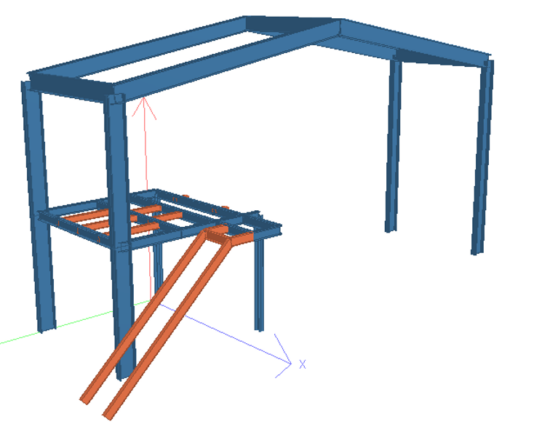

The design and analysis work began with modelling the new platform structure, integrating it with the existing steelwork.

The subsequent analysis was performed using STAAD Pro to assess the structure under normal operating, extreme wind and in service displacement conditions according to design criteria set out in BS EN 1991-1.

Additionally, comments for using existing steelwork and the design of foundations were also reported as part of the final work.

The outcome

DOCAN provided an efficient and safe design for the replacement access platform and verified the suitability of the design to the client’s requirements.

- We supplied the full detailed fab drawing design pack

- We built the structural model and detailed the drawings in Tekla

- We completed all the assessments in STAAD