At DOCAN Ltd Engineering Consultants, our Process, Chemical and CFD Team supports clients around the globe in solving some of the most demanding process, chemical and fluid dynamics engineering challenges.

One of the most complex problems in engineering design is creating a system that must work at both a global systems level and a detailed local level simultaneously. This challenge is particularly evident in advanced thermal systems.

A Large-Scale Feedback-Controlled Heating and Cooling System

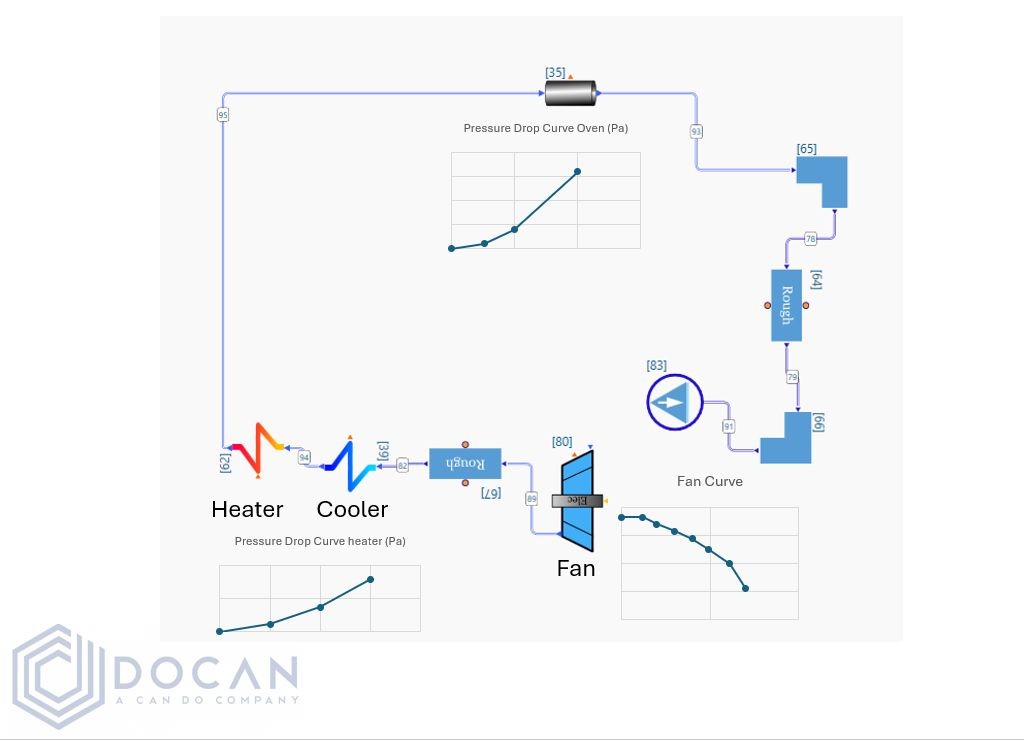

In this project, our client required the design of a very large, feedback-controlled heating and cooling system for a high-tech, high-value application. Only a small portion of the overall system is visible at the component level, yet performance depends on the interaction of every part.

To address this, we combined:

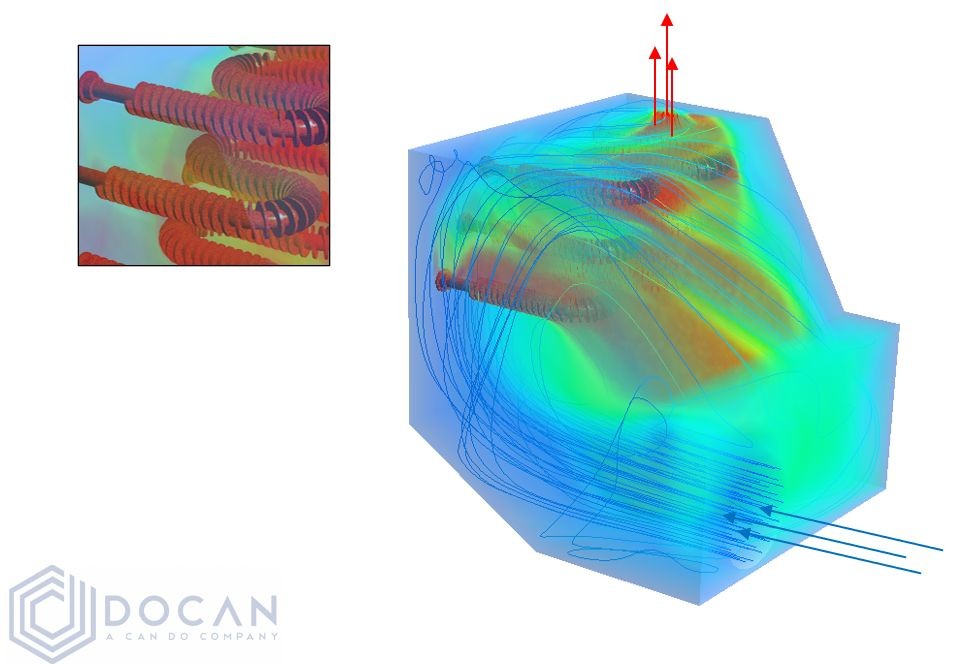

- 3D CFD modelling to capture local behaviour

- Pressure drop

- Heat transfer

- Cooling performance

- Efficiency curves

- A global thermal-fluid network model to integrate those local responses into the complete system

By generating detailed CFD-derived system curves and embedding them within a whole-system network model, we were able to accurately design and optimise overall performance before any hardware investment.

Integrating Digital Control into the System Model

The next stage involves incorporating the digital PID control system directly into the thermal-fluid network model. This allows us to simulate:

- Duty cycle adjustments

- Load variations

- Control tuning

- Energy efficiency optimisation

- Throughput maximisation

- Reduction of operational cycling

This approach enables the EC&I team to select the optimum control philosophy with confidence, ensuring a first-time-right design.

Technology and Expertise Behind the Solution

This work is delivered by DOCAN’s expert Process, Chemical and CFD engineers using advanced tools, including:

- AxStream for thermo-system modelling

- ANSYS Fluent for detailed CFD simulations

By combining detailed physics-based modelling with full-system integration, we can validate performance, optimise efficiency, and confirm functionality before Final Investment Decision (FID).

A First-Time-Right Engineering Approach

DOCAN has extensive consultancy experience supporting global clients across multiple sectors. Our multidisciplinary teams – Mechanical, Structural and Civil, Chemical, and Process – supported by advanced FEA and CFD capabilities, work together to deliver robust, validated designs.

If you would like to confirm your design works before committing capital expenditure, our team would be pleased to discuss your project.