Projects

Design of High Speed Impact Equipment

Industry

General Engineering

Services

Explicit FEA

Location

UK

DOCAN were contracted to make improvements to the prototype design of equipment which employs high speed and high energy impacts.

The Challenge

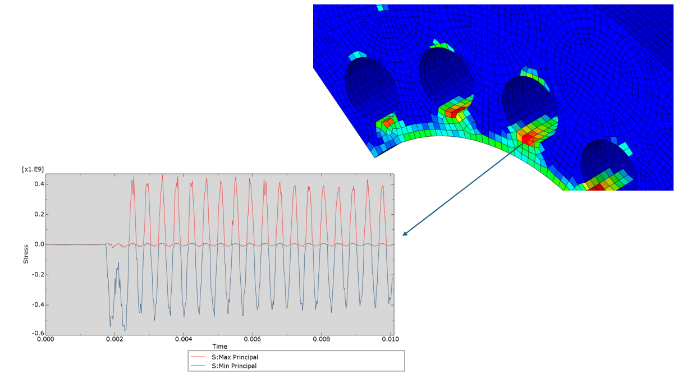

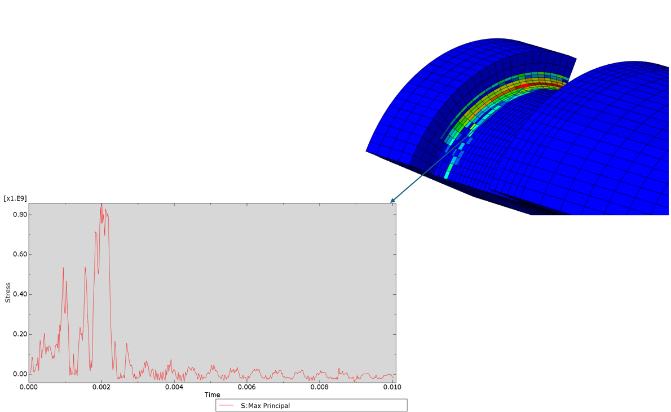

To design equipment for a product which includes repeated impacts. Each impact gives a single high tensile stress for some components while causing others to vibrate, which can accumulate many reversed stress cycles in a single strike.

How do we know which stresses are most damaging in fatigue and where we should focus our design effort?

The DOCAN Solution

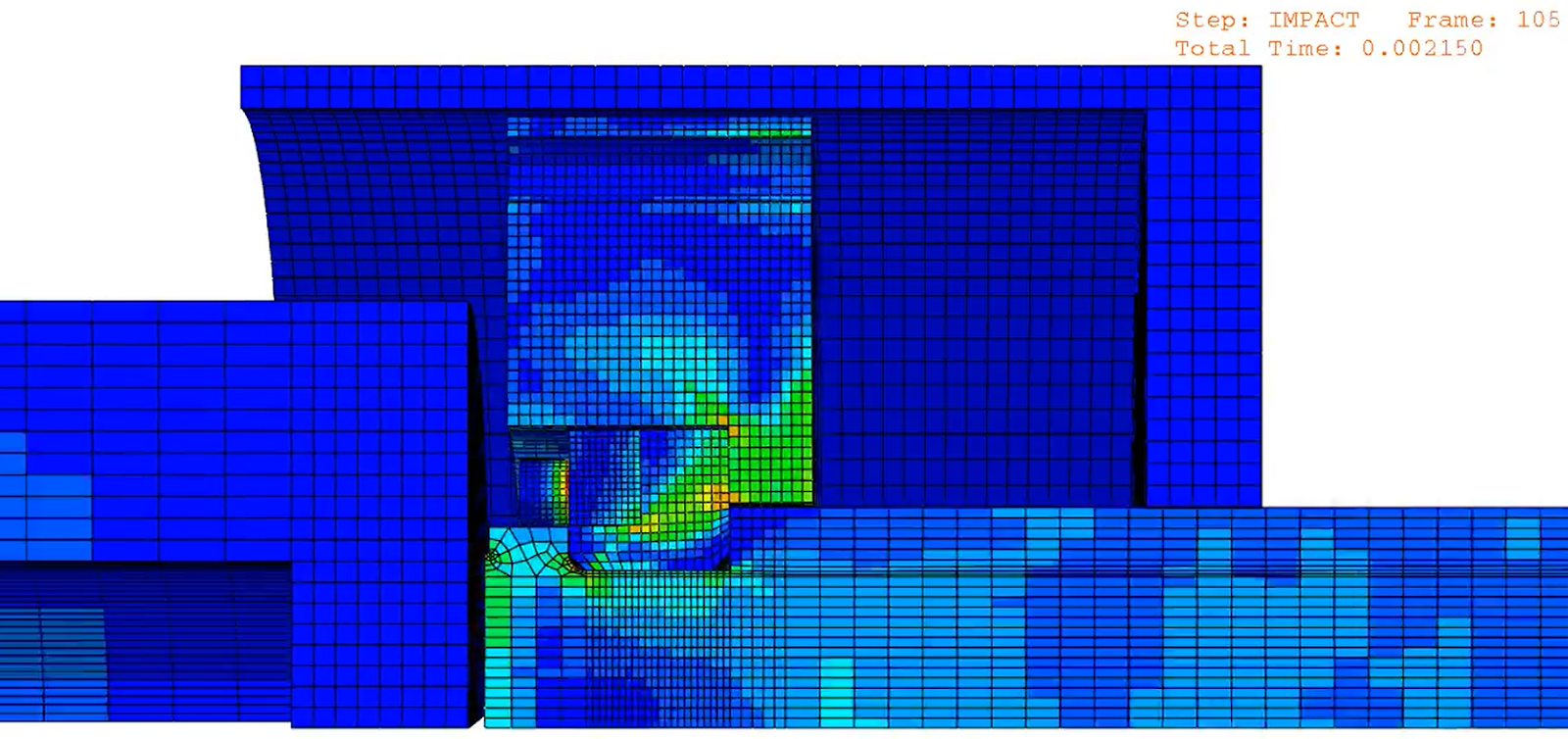

Using traditional implicit FEA for this dynamic event would be impossible, however by using explicit FEA we are able to capture the full transfer of energy through the system and the relative speeds of all of the different components at any point in time.

DOCAN’s experienced engineers use complementary pieces of software which allows us to use an advanced fatigue algorithm accounting for material differences, mean stress correction, bilinear stress states, and complex loading cycles which allows predicted life to be reported as a contour plot for every single element of the model.

The outcome

By producing a life contour plot of the entire system, it was possible for DOCAN’s engineers to visually show the effects of adjusting geometry and materials within the design space, resulting in an increase of several orders of magnitude in the expected design life of the equipment.