Projects

Fatigue and Creep Assessment of a Plastic Pressure Vessel

Industry

Manufacturing

Services

Design by Analysis, FEA, Mechanical Design, Pressure Vessels

Location

UK

DOCAN received an enquiry from a client pertaining to a stress analysis of a new tank design that will be going through testing and requires accompanying Finite Element Analysis to verify the design and to satisfy the request of the Notified Body (NoBo) to provide FEA verification.

The Challenge

The client needed independent verification and validation of their plastic tank design, aiming for long-term safety and regulatory compliance in liquid storage. The greatest challenge lay in ensuring the tank’s resistance to creep and fatigue over a 20-year service life with frequent cycling-failure modes rarely addressed by established design codes, which focus almost entirely on metals rather than plastics. With no standard code provisions for time-dependent deformation or fatigue in plastics, innovative approaches were required for material assessment, prediction, and safety calculations.

The DOCAN Solution

DOCAN developed a rigorous Design-by-Analysis methodology tailored to the unique needs of high-density polyethylene (HDPE), combining advanced finite element methods with custom material evaluation. Key features included:

- Supplementation of pressure vessel design code guidance with research data and real-world test results appropriate for HDPE, since conventional code rules are not directly applicable to plastics.

- Creep analysis based on power-law extrapolation, using literature data to compute long-term rupture and strain limits.

- Fatigue assessment using published S-N curves for HDPE with statistical adjustments for high survival probability.

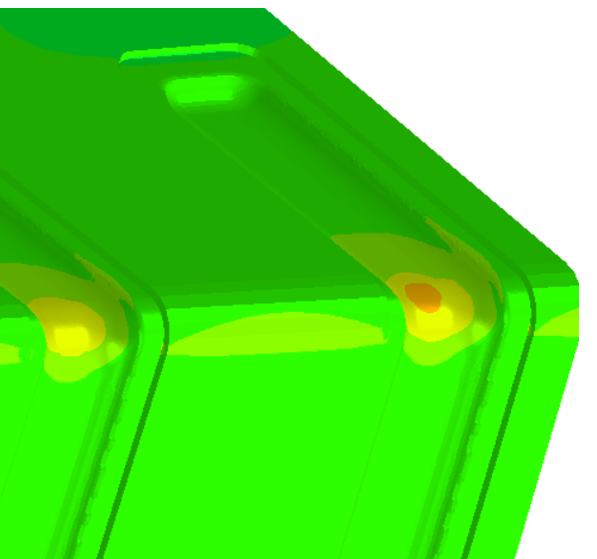

- The assessment confirmed the design’s integrity only after modifying key geometry details to lower local stresses and meet the stringent requirements for both creep and fatigue, ensuring practical long-term safety.

The Outcome

DOCAN’s material-led approach successfully bridged gaps in the design code, providing scientific justification for allowance stresses and long-term deformation in HDPE, backed by experimental and literature data. The client now has a thoroughly validated tank design, assured of regulatory confidence and operational longevity, with a comprehensive audit trail for the creep and fatigue performance of the plastic material.