Projects

Fitness For Service Assessment of Fire Damage Biodiesel Storage Tank

Industry

Petrochemical

Services

FFS, Digital Twinning/Reverse Engineering, FEA

Location

USA

A client in the USA had experienced a fire on their site which had damaged a biodiesel storage tank. The fire damage had distorted the tank’s shell as well as rupturing several welds connecting the head to the shell. As such, production at the client’s site was severely limited due to the tank being out of action.

DOCAN were contracted to perform Fitness For Service Assessment services to determine if the tank was still safe to operate.

The Challenge

The distortions in the tank’s shell potential would compromise its structural integrity, as well as potential degradation of the shell’s mechanical properties. DOCAN had to account for the real-world damage to ensure that our assessment was reliable and safe.

The DOCAN solution

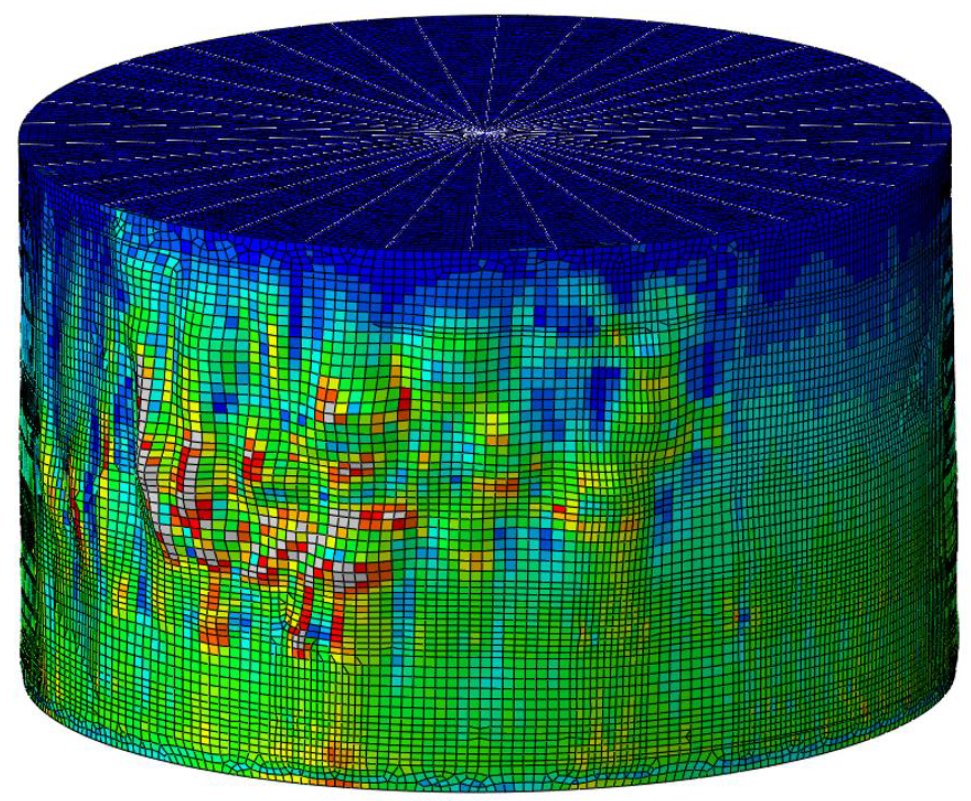

The assessment of the tank was completed to the requirements of the FFS code API 579/ASME FFS-1, specifically Part 11 (Assessment of Fire Damage) and Part 8 (Assessment of Weld Misalignment and Shell Distortion).

Aside from the obvious shell distortion effects, there were other forms of damage to be considered. As part of this FFSA work, DOCAN has conducted a review of the fire damaged inspection data (i.e., material mechanical properties and point cloud data) against the requirements of Part 11 (Assessment of Fire Damage) of the FFS code, which covers assessment of general forms of damage, such as:

- Mechanical distortion and structural damage.

- Degradation of mechanical properties.

- Degradation of metallurgical microstructure.

- Degradation in corrosion resistance and susceptibility to environmental cracking and creep damage.

- Presence of crack-like flaws in the pressure boundary.

- Residual stress changes.

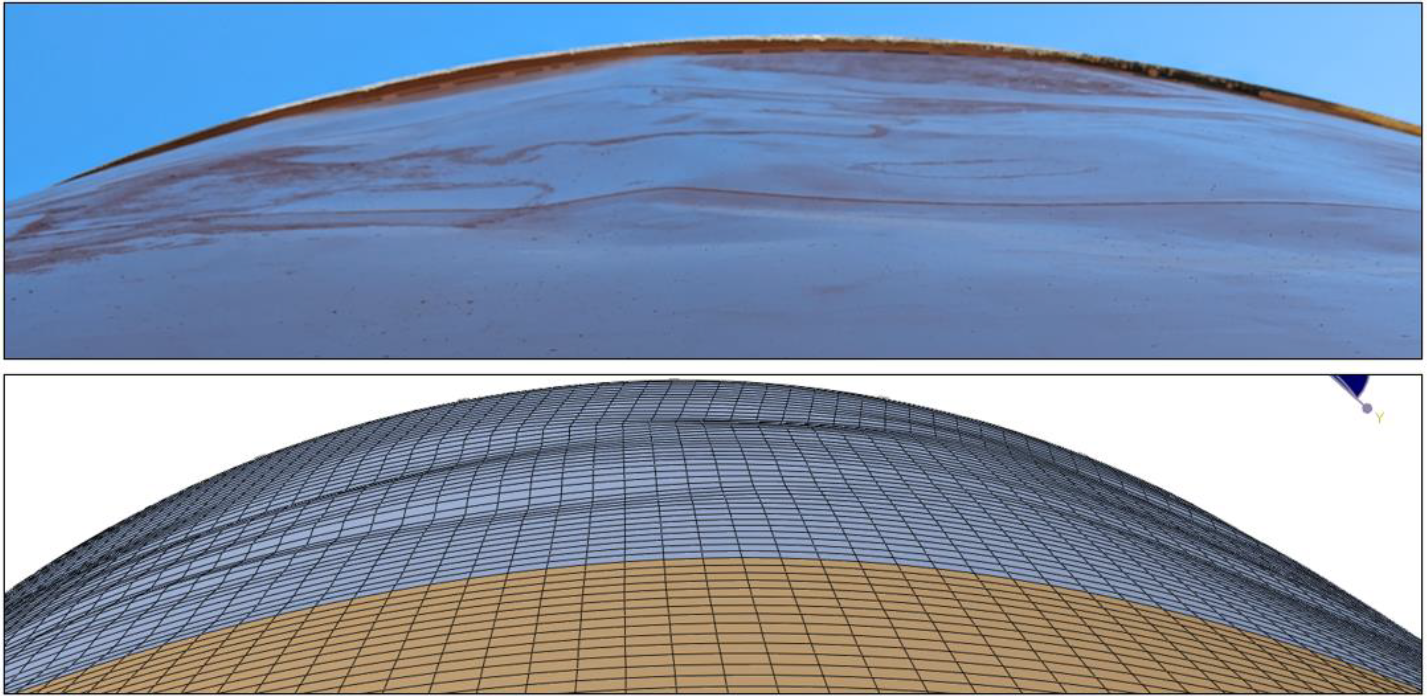

The structural assessment of the tank was performed by obtaining 3D laser scan point cloud data, post-processing this into useable CAD geometry, and then developing a Finite Element Analysis model to perform the assessment.

DOCAN have completed several similar project where our Digital Twinning expertise have been used to capture real world measurement data and turn this into useable, useful digital models that can be used to support design, assessment, and modification of parts and structures.

The outcome

DOCAN were able to demonstrate that the tank was still Fit For Service and the client could continue to operate the tank with some minor repairs, thus allowing production to continue at full capacity.