Projects

Fitness For Service Assessment of a Pressure Vessel

Industry

Manufacturing

Services

Fitness For Service Assessment, Repair

Location

UK

DOCAN were contracted by a client to perform a comprehensive Fitness For Service Assessment (FFSA) of a hot-running pressure vessel. The assessment was initiated due to concerns over structural integrity, corrosion, and crack-like defects in the vessel shell. The project required advanced engineering analysis and repair concept development to determine whether the stove could be safely returned to service.

The Challenge

The pressure vessel, constructed in the 1950s, had experienced significant local metal loss due to corrosion and crack-like defects in welds. The greatest challenge was the lack of complete inspection data, which made it difficult to quantify all flaws and assess their stability. Some flaws were found to be too long or deep to be shown stable with available data, and the presence of laminations in the shell plates added further complexity.

The DOCAN Solution

DOCAN applied a multi-faceted engineering approach combining advanced finite element analysis (FEA), fracture mechanics, and repair concept development:

- Fitness For Service Assessment with FEA using ABAQUS was performed to assess protection against plastic collapse and to determine stresses for assessment of crack-like flaws

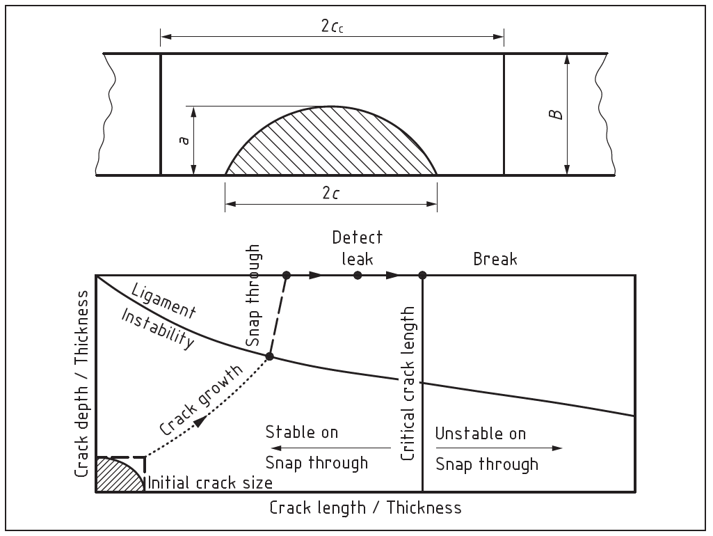

- Crackwise and BS7910 were used to assess crack-like defects. Where flaws could not be fully quantified, conservative assumptions were applied. Some flaws were shown to be unstable, while others passed under Leak-before-Break (LbB) arguments.

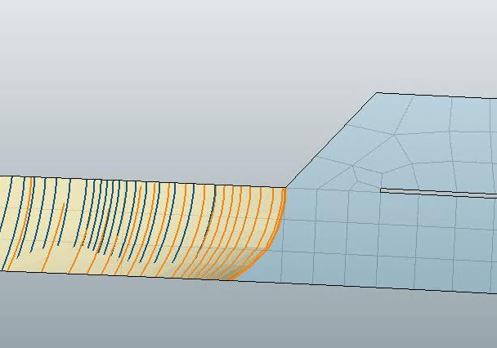

- Zencrack modelling was used to simulate crack growth paths and verify stress intensity factors. This confirmed that cracks tend to curve vertically rather than propagate circumferentially, suggesting potential for crack arrest strategies.

- Repair concepts included circumferential overplated bands, local patch repairs, and crack arrest ribs. Composite wrapping and full stove encapsulation were also considered.

- Statistical flaw assessment was attempted to justify FFSA without full inspection, but ultimately rejected due to the presence of long and deep flaws

The Outcome

DOCAN’s assessment concluded that while it could be possible to make a safety case with further engineering work, the vessel was damaged beyond cost-effective repair and should be removed from service. Without DOCAN’s assessment expertise and ability to identify and quantify critical issues, the client was at significant risk of experiencing a catastrophic failure, a risk that has now been mitigated against.