Projects

Reverse engineering for Refinery equipment

Industry

O&G

Services

Reverse Engineering, 3D scanning, Pressure Vessels, Piping

Location

UK

The challenge

Many of our refinery-based projects have required a Reverse Engineering service in order to facilitate the larger project. These projects include Pipe Stress Analysis, Fitness For Service Assessment, pressure vessel repair, and decommissioning amongst others.

The DOCAN solution

Many of these projects have required some element of reverse engineering, from surveying with 3D scanning to building full 3D CAD models of large pieces of equipment.

Some of these projects include:

-

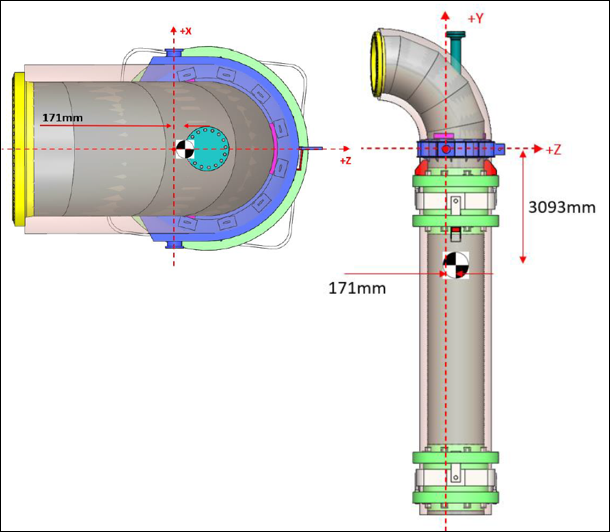

Power Recovery Train (PRT) Inlet Piping FEED, FFSA and repair:

- Engineering surveying

- Development of 3D models of existing equipment

- Pipe Stress Analysis and FEA

- Design of attachments for decommissioning lifting -

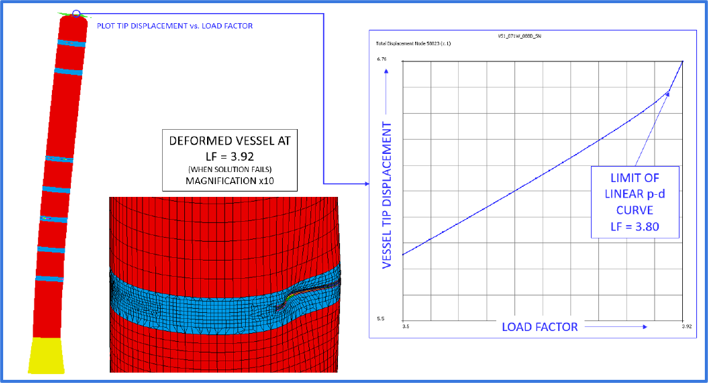

Deisobutanizer Column FFSA and repair:

- Detailed FEA and Level 3 FFSA of heavily corroded, +70m tall pressure vessel, based on Creaform surface scanning data

- Design of insert plate repairs and creation of repair drawing pack -

Pressure vessel decommissioning and super lift:

- Reverse engineering and 3D CAD modelling for detailed mass and CoG calculations

- Design and assessment of lifting connection points for lifting over live refinery equipment

The outcome

Reverse Engineering has played a key part in many of our projects and allowed us to provide our clients with a full engineering service to meet their needs.