Projects

Steam Dispersion CFD Analysis

Industry

Power Generation

Services

CFD

Location

UK - England

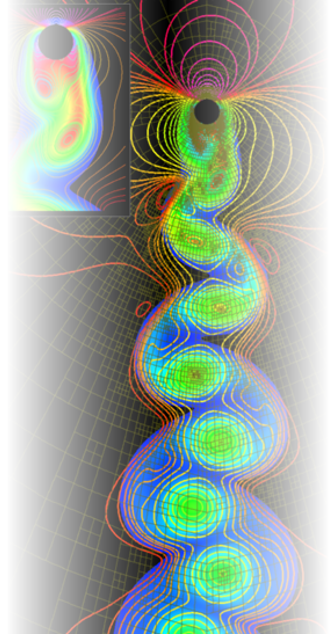

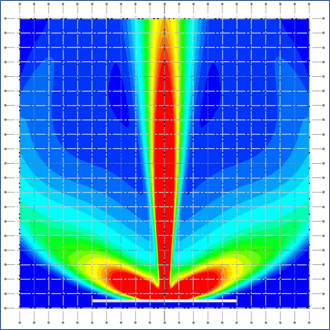

A steam line of part of a power generation system experienced a circumferential crack and began releasing high-pressure, high-temperature steam. In the interest of health and safety, DOCAN were contacted to evaluate the boundary wherein the steam could pose a danger to personnel.

The challenge

This jet of steam can be problematic for various reasons including scalding risk, high velocity flow, and large pressure fluctuations / acoustic risk.

Establishing the area where this issue would be serious requires understanding where the steam travels while expanding from highly pressurized in the pipe to ambient pressure, which is not always intuitive, especially for supersonic fluid flows as caused by the design conditions present here.

The DOCAN solution

Using Siemens FloEFD DOCAN produced a model of the steam flow from the damaged pipeline, the results from which were used to define an exclusion zone around the pipe based on the temperature, velocity, volume, and pressure of the ejected steam.

The outcome

The client has been able to ensure the safety of workers in the area by defining an exclusion zone whilst being able to plan in repair activities, with the advantage of knowing what the effects of increasing crack size would be and the potential Health and Safety implications.

Project summary

| Task | Application | DOCAN Associate Expertise | CFD | Siemens FloEFD | Health and Safety |

|---|---|---|---|---|---|

| CAD geometry | Build 3D model | ||||

| CFD model building | Modified Parts and Meshing | ||||

| Flow rates & boundary conditions | |||||

| Reporting | Information summary |