Assessing defects & revamping old technology through FEA

05 / 07 / 24

Using a combination of methods, we brought life back into a damaged energy system.

We’re often designing new technology, but there is significantly more old technology which still has plenty of life remaining.

Recently, our Advanced Engineering team has been working on a major energy project for one of our international clients – where there are varying degrees of damage.

To conduct this work, we used a combination of methods:

- Materials testing to characterise strength, toughness, ductility, transition, composition, and microstructure

- Defect inspection to classify the defect as having cracks, poor fusion, laminations, phase change, etc

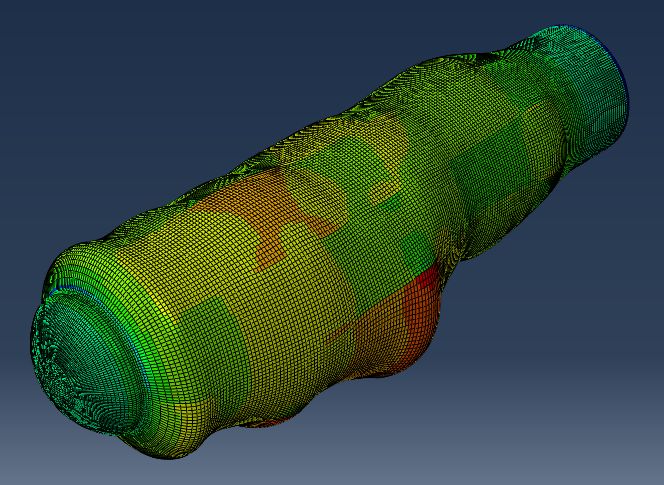

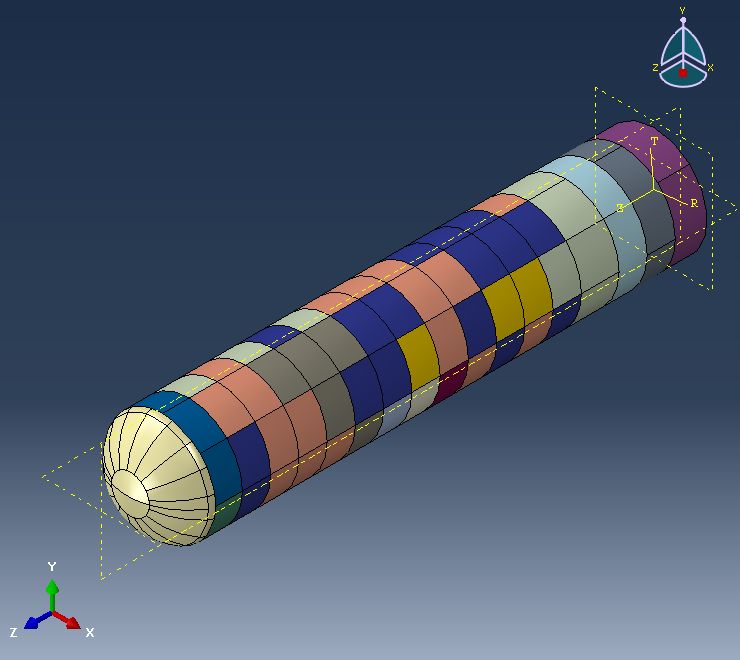

- CAD modelling with SolidWorks to describe the geometry of the equipment and its defects

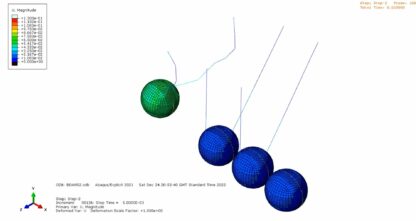

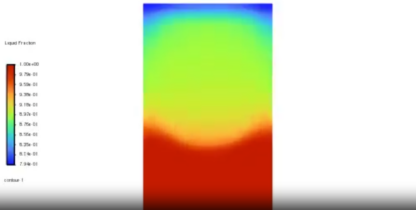

- Finite Element Analysis using Abaqus for linear and non-linear to determine stress, stability, collapse resistance, stress intensity, local stress, thermal stress, linearized stress, etc.

- Fracture mechanics using the FAD approach with TWI Crackwise to complete BS7910 Options 1 to 3 FAD assessments and confirm if defects are stable, and if they will grow.

This type of work helps to keep industry moving efficiently and safely. DOCAN can work with a variety of different design codes to design new systems or keep current systems up and running.

Get in touch with us to find out how we can help with your project.