Consultancy

Piping Engineering Consultants

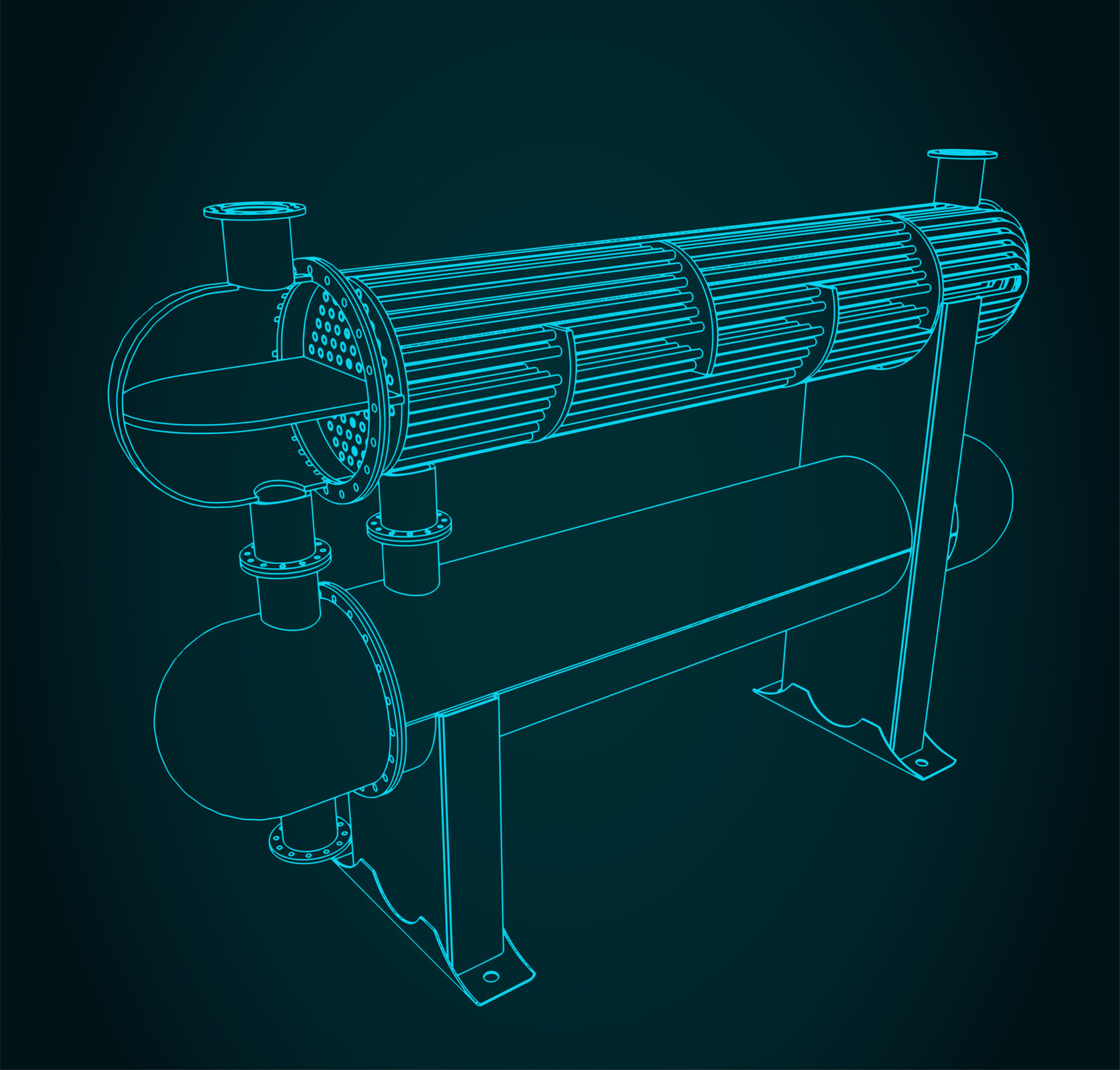

We deliver efficient heat exchanger engineering solutions for process and power applications, supporting industries such as nuclear, offshore, chemical, water, industrial, and refining.

Our heat exchangers expertise

At DOCAN, we have extensive experience in the design, assessment, and optimisation of heat exchangers across a wide range of industries. Our engineers apply both manual calculations and advanced simulation techniques to ensure reliable, safe, and efficient solutions tailored to client requirements.

Some examples of our heat exchanger lifecycle experience include:

- Design, re-rating, and upgrading of shell-and-tube and high-pressure heat exchangers.

- Thermal and mechanical analysis using leading software, from basic calculations to full 3D simulations.

- FEED, Detailed Design, and production of manufacturing and construction documentation.

- Fitness For Service Assessments, including fracture mechanics and code-based evaluations.

- Assessment of nozzles, internals, and connected piping, from simple calculations to advanced 3D FEA.

DOCAN’s heat exchanger services

We utilise a range of specialised software tools to complement our engineering knowledge, enabling us to perform highly accurate simulations and calculations:

Design and Calculations

- PTC MathCAD for manual engineering calculations.

- Hexagon PV Elite for pressure vessel and heat exchanger design.

- HTRI for process and thermal design.

- AxStream for thermal-fluid optimisation.

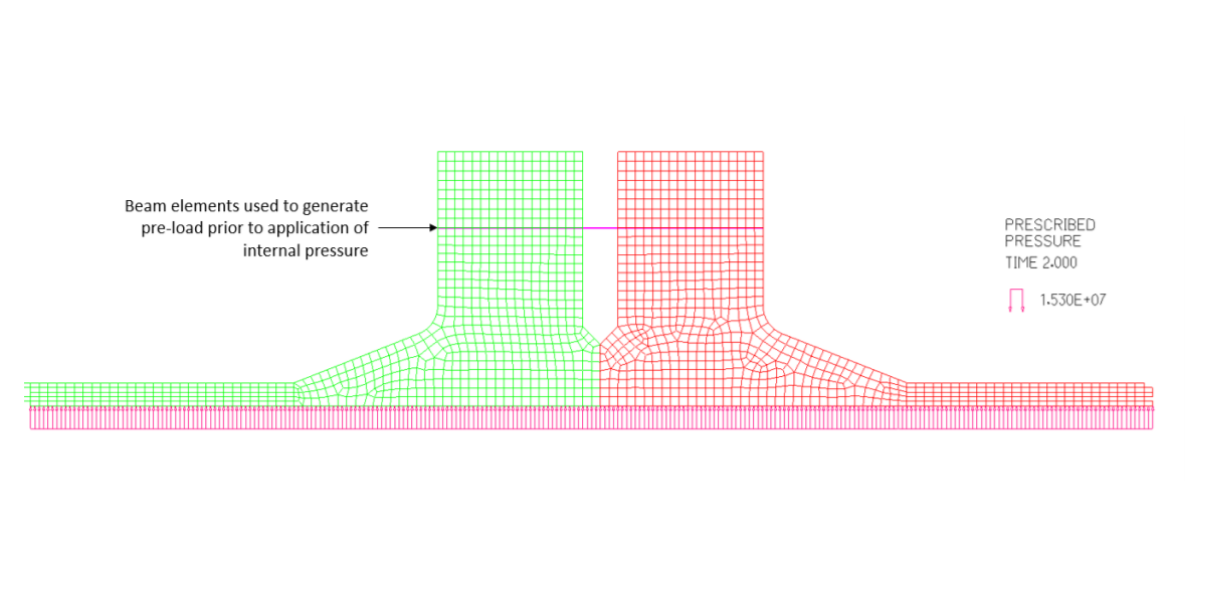

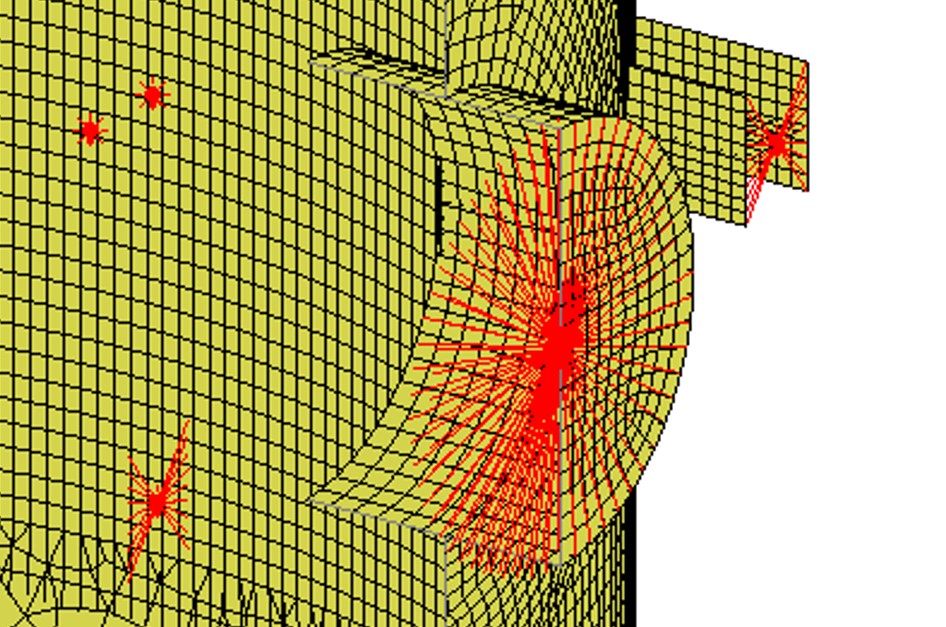

Finite Element Analysis (FEA)

- ANSYS or ABAQUS for structural assessments

- PRG NozzlePRO for nozzle evaluation, where suitable.

- Zencrack and Crackwise for 3D crack modelling and fracture mechanics.

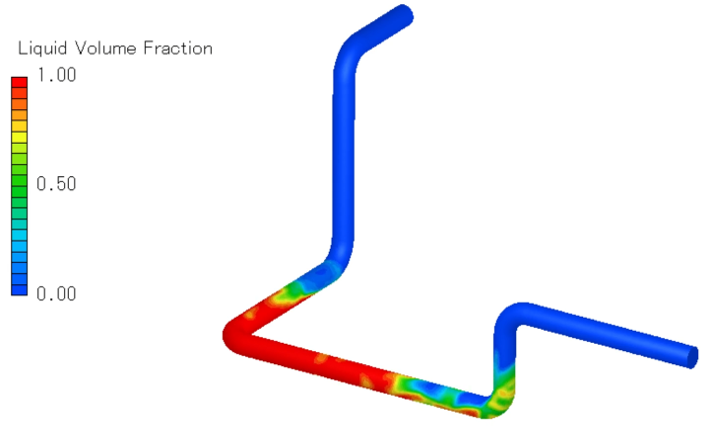

Computational Fluid Dynamics (CFD)

- ANSYS Fluent and ANSYS CFX for flow and thermal simulations.

- Thermal and mechanical coupling for complex interaction studies.

Pipe Stress and Structural Modelling

- CAESAR II and ROHR2 for stress analysis.

- SolidWorks or BricsCAD for detailed 3D and 2D modelling.

Our services include:

- New design of shell-and-tube heat exchangers.

- Re-rating and upgrading existing units to meet new process demands.

- Fitness For Service assessments for ageing or damaged equipment.

- Minimum Design Metal Temperature (MDMT) evaluations.

- Complete design reviews where original documentation is missing.

- Process system support, including condensers, pre-heaters, and chillers.

Industries

DOCAN have extensive experience working within the below industries, but our expertise can be applied to the heat exchanger requirements of projects within any sector.

Why work with DOCAN?

Choosing DOCAN means working with a team that combines deep technical expertise with proven project experience. We don’t just apply design codes – we understand their intent, limitations, and how to integrate them into complex real-world applications.

Key reasons to partner with us:

- Proven track record delivering successful projects across pressure vessels and heat exchangers.

- Expertise in both mechanical and process engineering, giving us a holistic approach to problem solving.

- Capability to work with modern and legacy systems, including projects where original design data is missing.

- Advanced use of simulation and analysis tools for greater accuracy, efficiency, and reliability.

- Commitment to safety, compliance, and delivering cost-effective solutions.

At DOCAN, we are dedicated to helping clients improve performance, extend equipment life, and ensure compliance with the most stringent industry standards.