Providing expert analysis and problem-solving using insights from condition monitoring data through a range of advanced engineering services.

Effective condition monitoring solutions

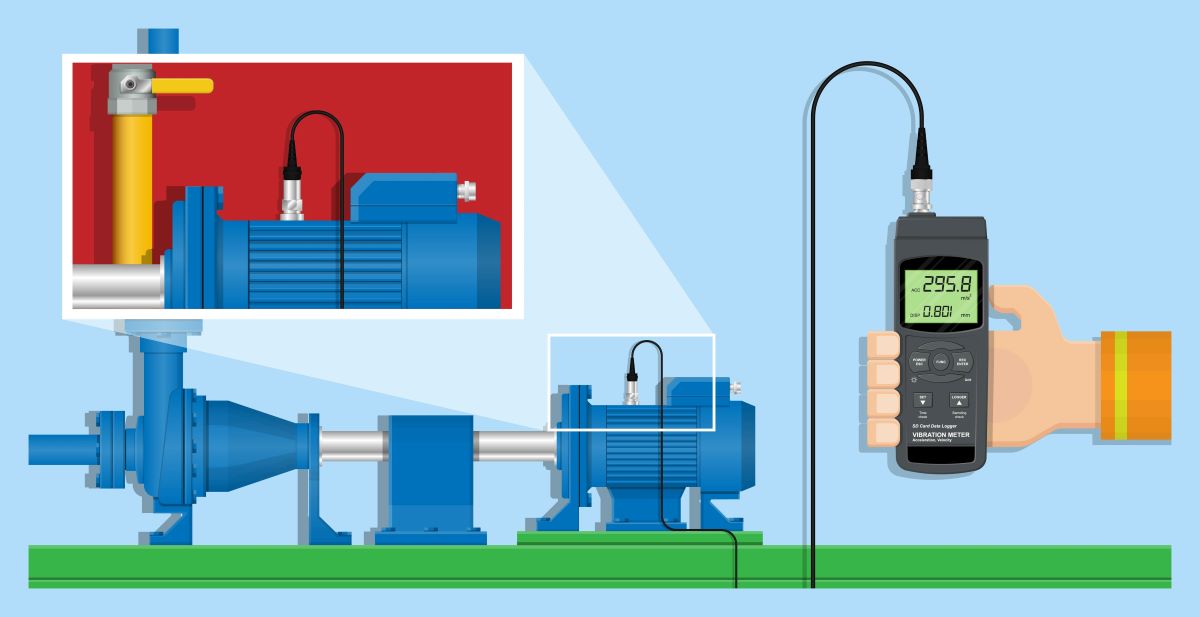

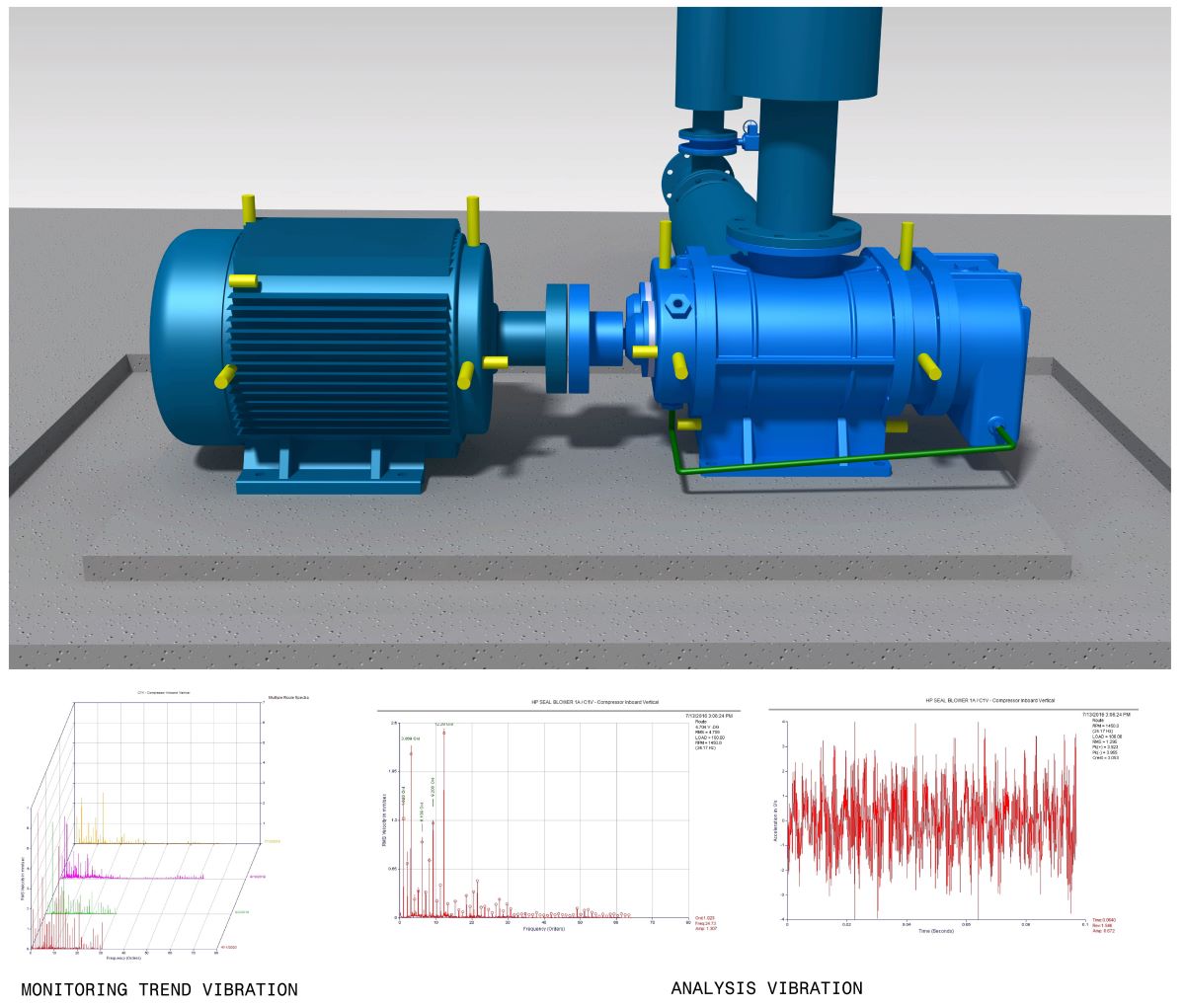

Condition monitoring is essential for identifying potential issues, but the key is knowing how to resolve them and prevent them from happening again. At DOCAN, we specialise in determining the root cause of any issues raised through condition monitoring and providing effective solutions to fix the problem and prevent future occurrences.

Our team has extensive experience helping clients address issues such as vibration, using advanced engineering techniques like Finite Element Analysis (FEA) to enhance the accuracy of results. By combining expert problem-solving with cutting-edge technology, we ensure that your systems operate efficiently and reliably over the long term.

How we can help

We have an experienced team of engineers with specialised skills in high-level engineering techniques and expertise spanning a range of applications across various industries, allowing us to tackle intricate and complex engineering challenges effectively. We are Corporate Members of the Vibration Institute which enables us to offer industry-best practices for cutting-edge solutions and ensure our methods and technology are consistent with the body of knowledge within the industry.

What sets us apart is our ability to identify and solve problems, particularly in demanding scenarios. While maintaining system reliability is crucial, we recognise that condition monitoring is just the first piece of the puzzle.

DOCAN provides comprehensive engineering support that goes beyond basic monitoring, addressing underlying issues to ensure the optimal performance of your systems.

Some of the problems we can help to solve include:

- Solving vibration issues found through vibration analysis

- We are corporate members of the Vibration Institute and can solve issues through detailed analysis and mechanical design iterations.

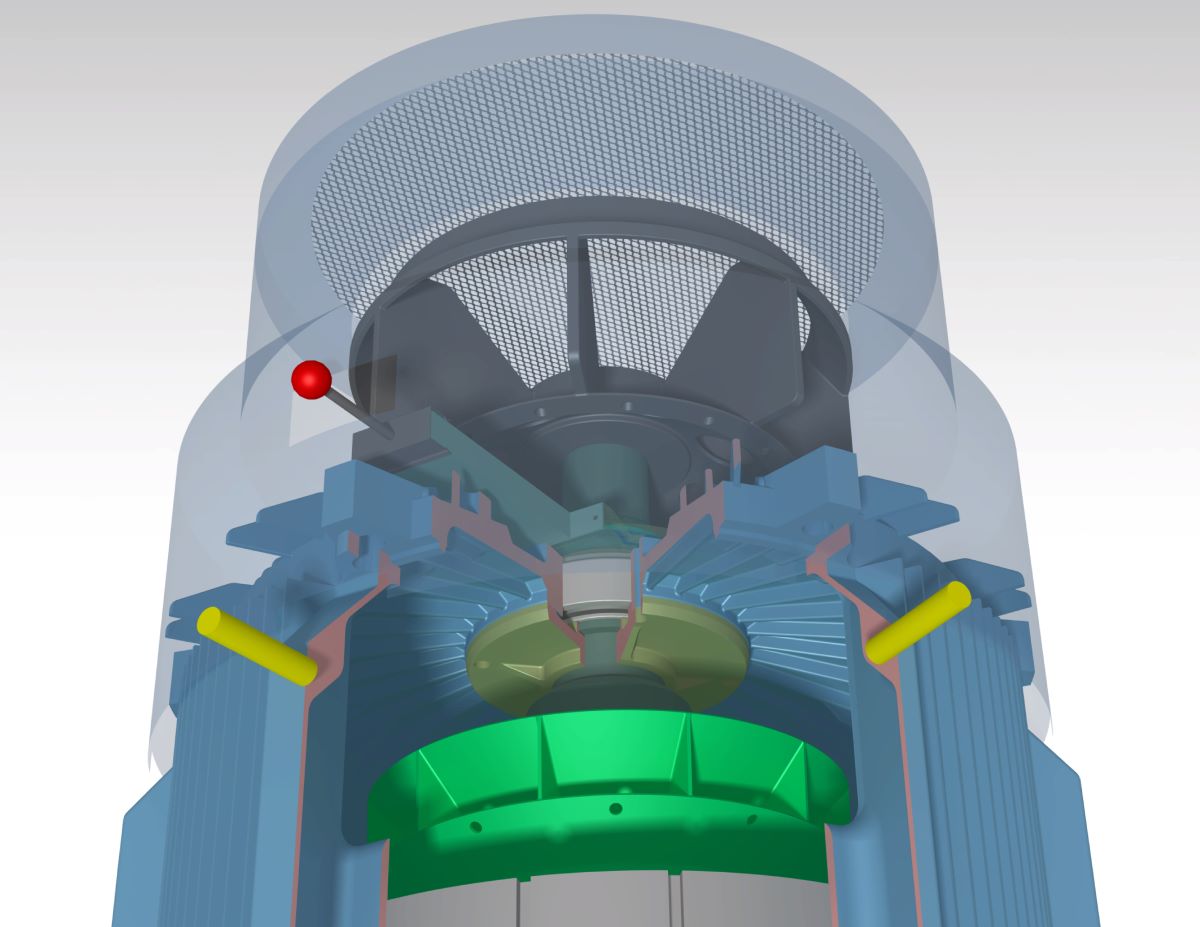

- Solving thermal issues on rotating, electrical, or other equipment

- Preventing end of life by identifying excessive temperatures and any heat-related issues

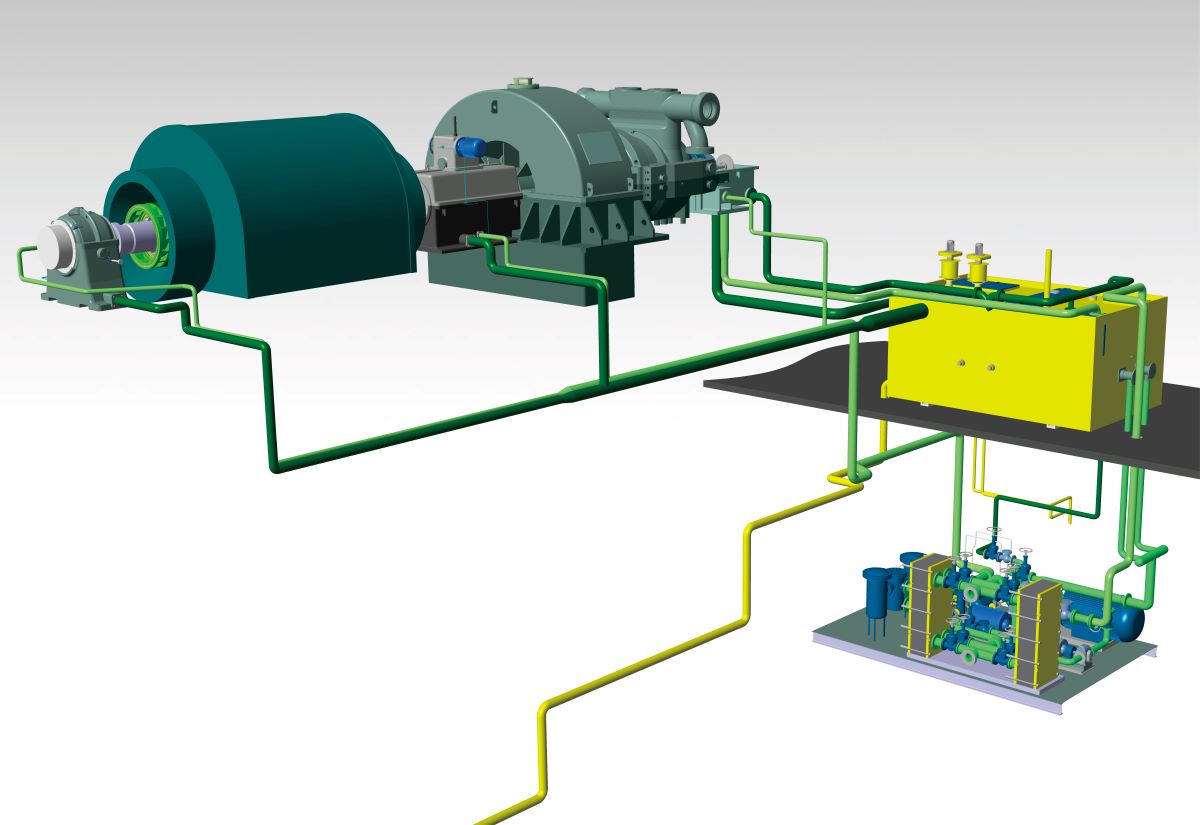

- Solving lubrication problems found through lubricant analysis

- Identifying issues and devising solutions tailored to optimising practices, reducing wear and improving the reliability of equipment

As a multidisciplinary consultancy, we can implement advanced techniques such as FEA to solve some of the most complex problems experienced in machinery and systems.

Why work with DOCAN?

Interpreting condition monitoring data is just one part of the equation; developing a suitable strategy for effective asset maintenance is equally crucial. At DOCAN, we provide a wide range of services, including training, measurements, and consulting, to support your asset management needs.

Even if you have condition monitoring systems in place and a maintenance plan to identify issues before they arise, you may require deeper insights to fully understand the potential effects of damage, assess the effectiveness of remedial actions, or explore redesign options for a part or system. That’s where we come in.

DOCAN offers an extensive suite of engineering support services, from R&D to decommissioning. We utilise advanced vibration and thermal design and assessment methods, employing state-of-the-art technologies to tackle your engineering challenges head-on. With our expertise, you can ensure the longevity and reliability of your assets while optimising performance.