We are an advanced engineering consultancy with digital twinning capabilities, offering full engineering support to client’s projects.

Experienced digital twin consultants

At DOCAN, our team of experienced digital twin consultants brings expertise across a wide range of engineering applications. We specialise in creating digital twins to support clients where critical information may not currently exist, providing valuable insights for various projects.

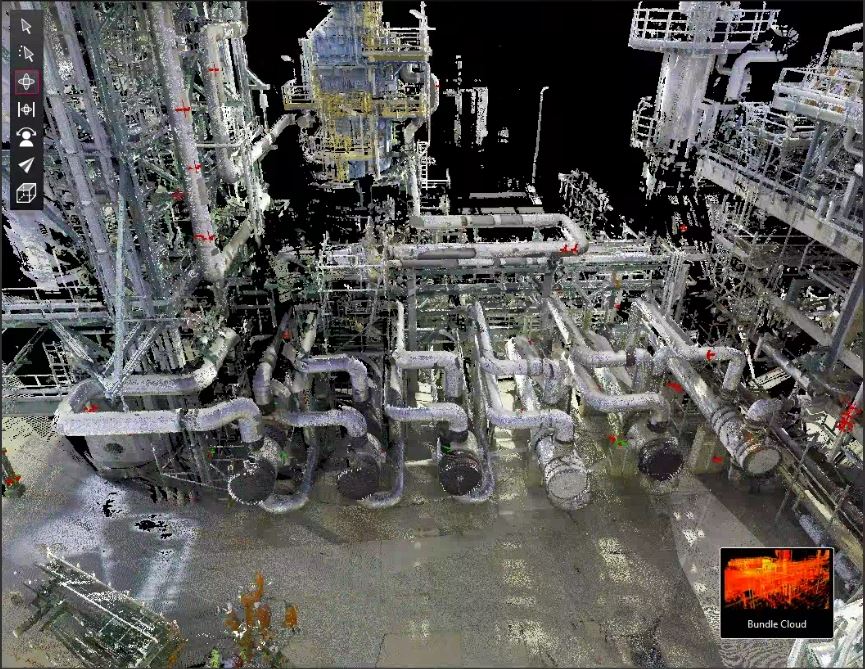

Our multidisciplinary team of skilled engineers works across major industries, including construction, energy, and mechanical engineering. With access to the latest technology and advanced engineering software, we handle everything in-house, including tools such as Leica Laser Scanners, total stations and trackers (RTC360, P40/P50 long-range scanners, and TS07 and TS16), Hexagon, FARO and Creaform technologies for CMM, metrology grade laser scanners and laser trackers.

Whether you need a digital twin for successful reverse engineering, a Fitness For Service (FFS) assessment, or to inform the design of a new component or structure, we’ve got the expertise and tools to deliver precise, reliable solutions tailored to your needs.

Digital twins for equipment & structures

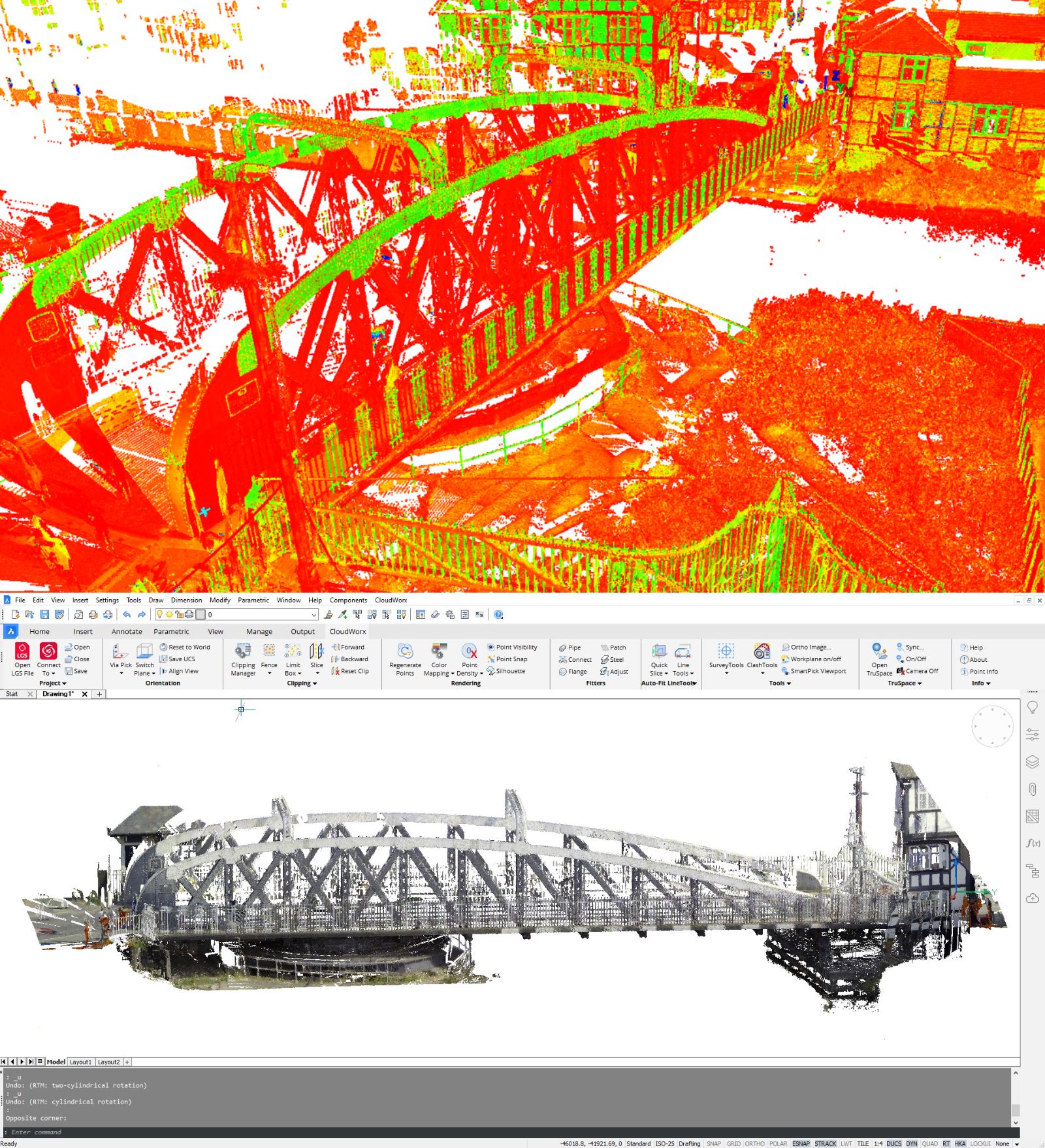

Our digital twin services work seamlessly with our 3D laser scanning expertise. By using precise scan data, we create highly accurate digital twins that can inform the design of new structures or systems. We use metrology grade scanning equipment where capturing high resolution detail is important, through to terrestrial scanners for larger scale, but still impressive levels of detail.

Digital Twinning may also be required as part of your Building Information modelling (BIM) project and this is something where we can help you too.

We start by capturing raw scan data from the physical asset and then put it through a detailed post-processing phase to refine the data. The result is a highly accurate and detailed digital representation of the equipment or structure, providing a valuable tool for engineering, analysis, and design. Whether for new projects or ongoing maintenance, our digital twins deliver the insights you need.

Our approach

We handle every aspect of our client’s projects in-house, eliminating the need for them to invest in expensive equipment or software.

With internal access to 3D laser scanning technology, digital twinning software, and CAD systems, we manage the entire process from start to finish. We take care of the whole project, from initial scans to the creation of digital twins and anything beyond.

Our approach is simple and efficient:

- On-site measurement: We use leading equipment such as the Leica RTC360, P40 long-range scanner, and Total Station to capture accurate data of your system.

- Post-Processing: We refine the raw scan data and create a global model that serves as a digital twin.

- Data integration: We then export the processed data into a CAD system, where it can be easily accessed for further use.

- Project foundation: This detailed CAD model becomes the foundation for a variety of engineering tasks, from design updates to reverse engineering and more.

How digital twinning can help your project

A digital twin offers a highly accurate digital representation of a physical system that can be analysed and used as a foundation for engineering tasks, without the need for direct access to the physical asset. This powerful tool allows for seamless assessments and modifications, even from remote locations.

While creating a digital twin is often a critical part of Reverse Engineering, it also plays a key role in other services we provide, such as Fitness for Service (FFS) Assessments and new design work. By integrating digital twins into a wide range of engineering applications, we ensure precise, data-driven solutions that enhance the efficiency and accuracy of your projects.

Why choose DOCAN for digital twin design?

At DOCAN, we offer comprehensive engineering support throughout the entire project, ensuring you’re never left to solve problems on your own. Unlike typical scanning companies that simply deliver a basic CAD model, we go beyond by providing the full range of engineering services you may need once the digital twin is created – whether it’s Fitness for Service (FFS) assessments, reverse engineering, or other specialised solutions.

Our approach is cost-effective, as clients don’t need to invest in expensive surveying equipment. Plus, with our deep engineering expertise, we understand exactly what’s needed from a digital twin. This ensures that all the necessary data is collected accurately from the start, saving time and resources while delivering high-quality results.