How to optimise thermo-fluid hydraulic design in ring main systems

18 / 07 / 25

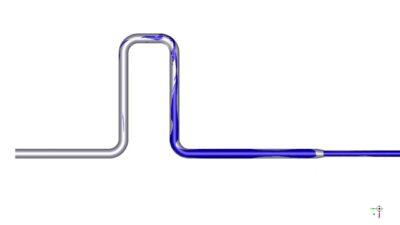

This pre-FEED study looks at the thermo-fluid hydraulic challenges of pumping thick fuel oil across long distances and elevations.

This brief outlines a pre-FEED study focused on efficiently pumping thick fuel oil through a ring main system.

In this ring main system, we are pumping thick fuel oil over a large distance and large elevation to its multi-usage points.

Part of our task here is to size the pump and the main pipeline to give efficient flow. We can then estimate the next stage of the project (time/cost/details) thereafter.

Key considerations

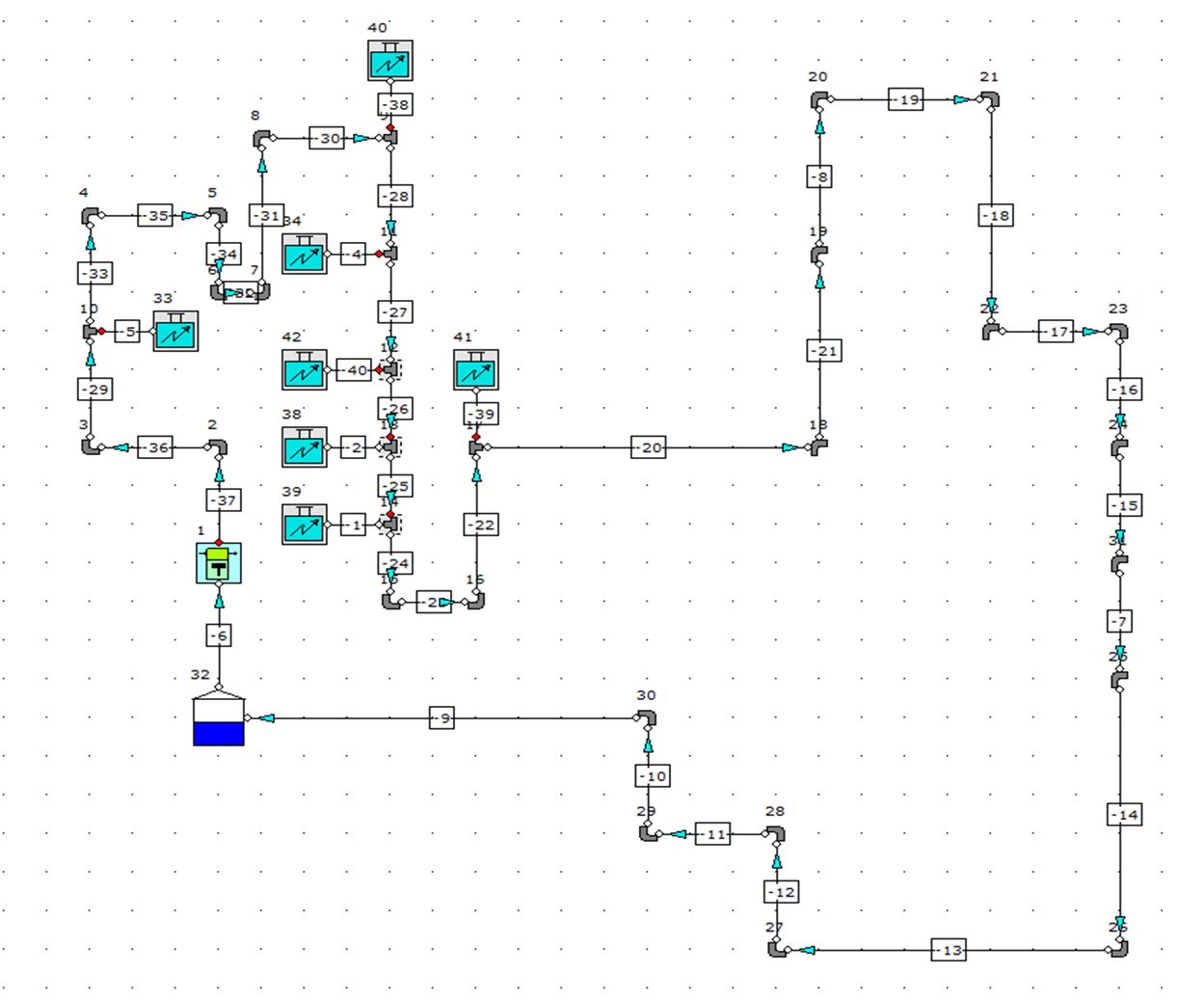

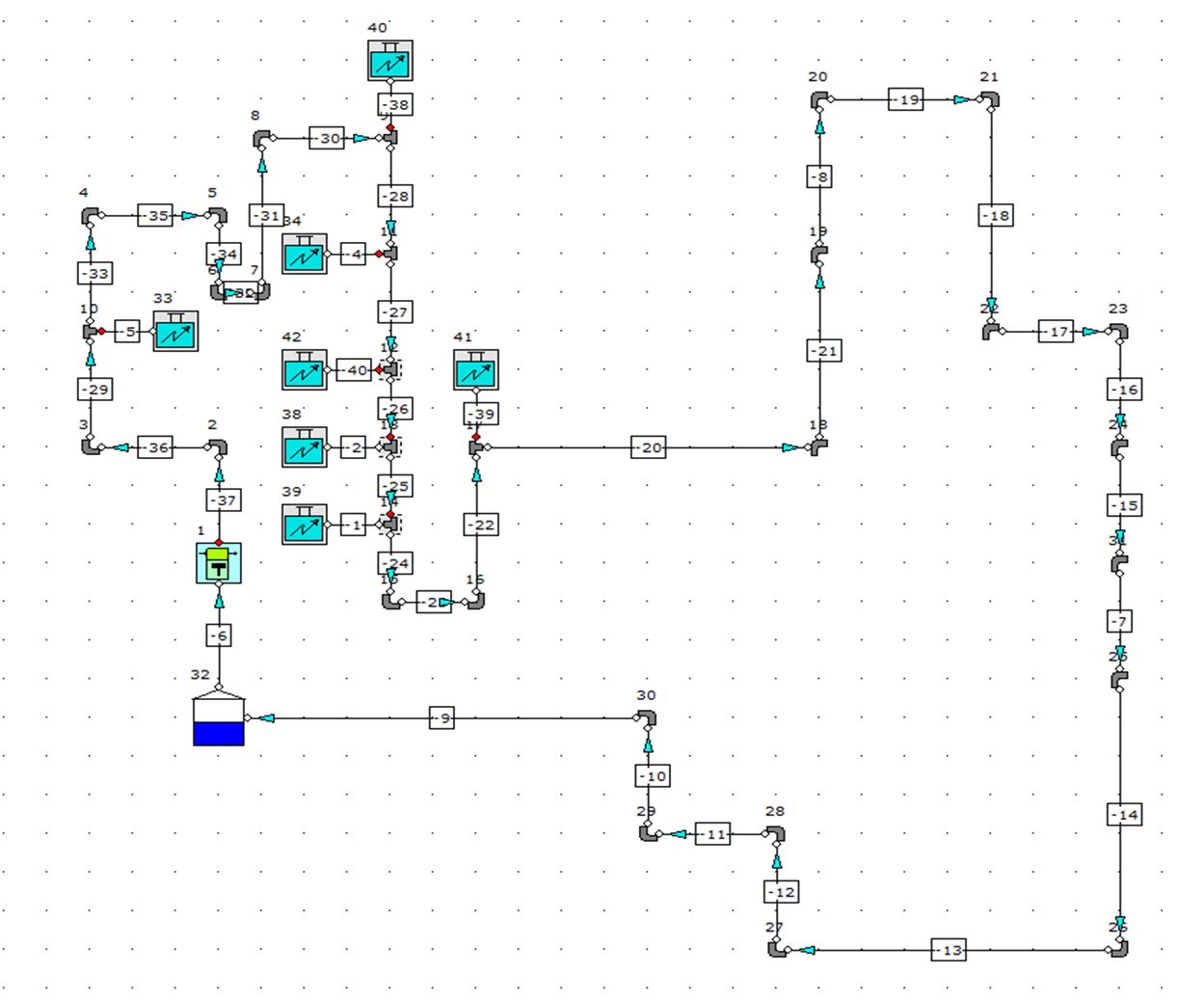

- Pre-FEED – so only modelling the larger parts of the system, with simplifications used for smaller sub-systems

- Positive Displacement pump, or multi-stage centrifugal pump – noting large distance, large elevations and large flows (+10kg/s)

- Size pipe – having efficient pumping and flow, and limit excessive turbulence and velocity, and cost

- Avoid cavitation, by ensuring our Head pressure is sufficient (i.e. NPSH is higher than our NPSHa)

Conclusions from task

- Pump selected – efficient positive displacement pump

- Size selected – sized for acceptable flow and minimal pressure drops versus time and cost

- Confirmed pump and pipeline can deliver requirements efficiently

- Onto the next stage of the project with confidence.

If you’re looking for thermo-hydraulic designs for your system, get in touch with DOCAN.