Machines and Rotating Equipment with AxStream Bearing

Designing rotating equipment isn’t just about CAD models - it’s about making sure machines actually work, and work for the right amount of time.

At DOCAN, we have experienced engineers and designers, and they use CAD to help in the process. One of our favourite systems of machine design is SolidWorks. But it does not really help in the mechanics of making sure your machine or rotating equipment actually works, and works for the right prescribed amount of time.

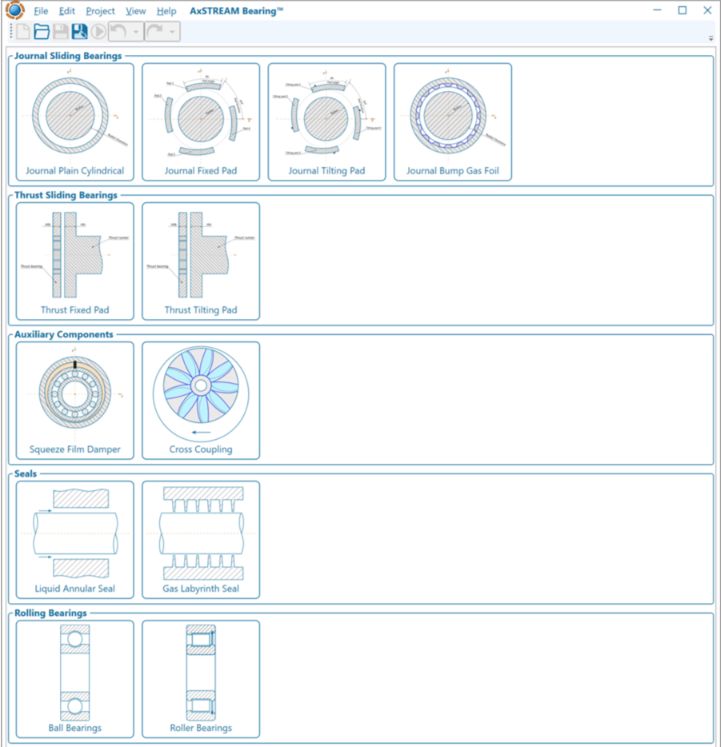

One of our standout technologies is AxStream, which includes tools for designing bearings, seals, shafts, turbines, pumps, compressors and more.

Designing Rotating Equipment in Practice

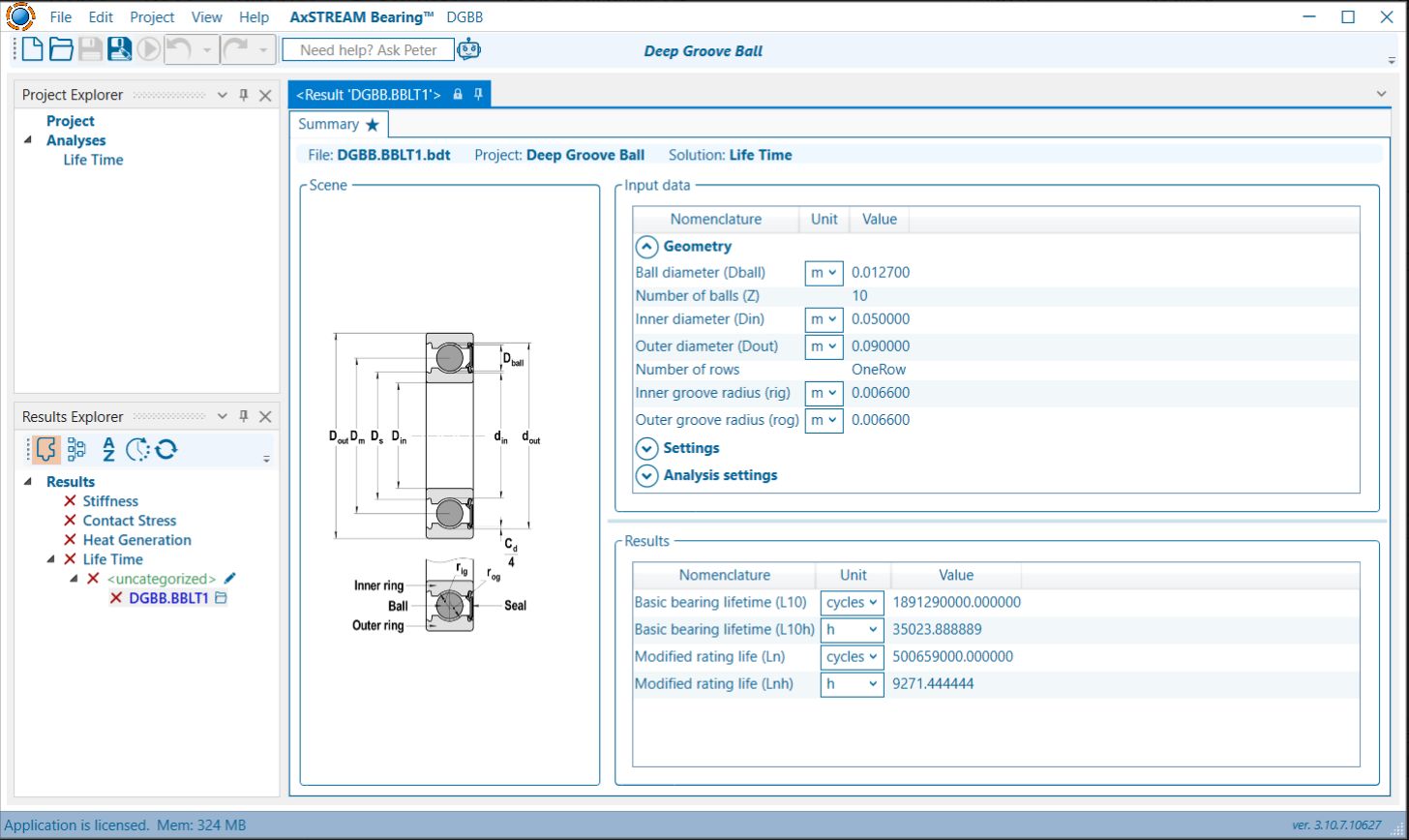

In this example, we are designing rotating equipment as part of a machine. We have determined the shaft loads, and now we need to select the right bearings and ensure they have sufficient life.

If you have ever set up your own calculations, you know that for each type (hydrodynamic, hydrostatic, plain, roller, magnetic, etc.) you can burn an inordinate amount of time.

Introducing AxStream Bearing

We bring you AxStream Bearing — used for basic machines, all the way to rocket engines!

In the example, we have selected a deep groove ball bearing and are selecting the size based on the requirements. In the end, our selection gives us just over 9000 hours of life which is adequate for our purpose.

We also know the generated heat (or cooling requirement), we know the stiffness which is fed back into the shaft design, and we have great confidence our bearing will work. If things change, we can also quickly modify our design with confidence.

If you also want to simplify your design process, but go much further into the design, then come and talk to the team who can help you either in consulting or supplying AxStream Bearing.