Projects

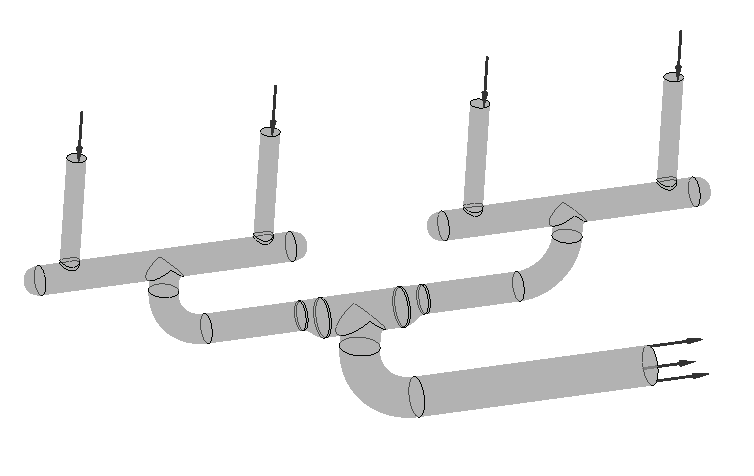

3D CFD analysis: Piping System Metallurgy upgrade For Oil Refinery

Industry

Oil & Gas

Services

CFD

Location

US

DOCAN were contracted to validate and optimise a piping system design for use within a highly corrosive and erosive system on a top tier site in the US.

The Challenge

The project aimed to replace corroding piping with a corrosion-resistant alloy to mitigate the risk of pressure boundary failures caused by accelerated corrosion and erosion. Such failures pose significant risks to personnel safety, plant operations, and operational costs.

DOCAN’s task here was to verify that flow-accelerated corrosion was not an issue with the new piping system.

The DOCAN Solution

To address the challenge, DOCAN were required to validate a piping system designed for highly corrosive and erosive environments. The solution involved:

- Replacing the affected piping with a corrosion-resistant alloy (CRA) that offers superior durability and mitigates existing corrosion and erosion problems.

- Eliminating unnecessary dead ends and replacing them with elbows of suitable thickness to enhance reduce areas prone to erosion and corrosion.

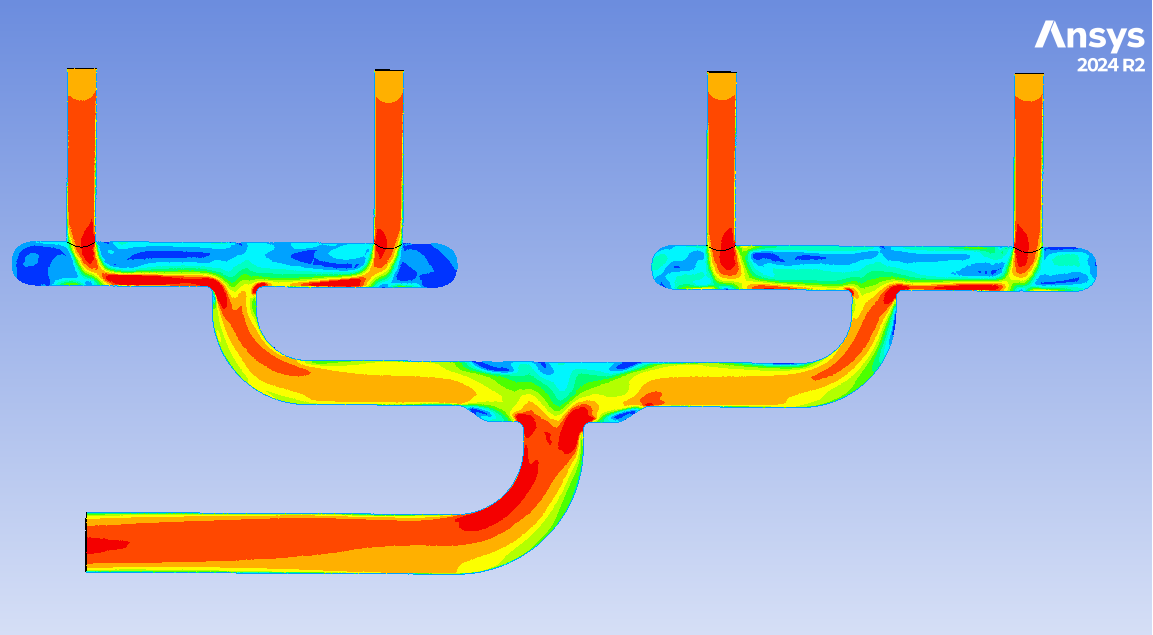

To validate and optimise the proposed design, DOCAN utilised advanced CFD (Computational Fluid Dynamics) simulations. This analysis allowed for:

- Flow Behaviour Analysis: Simulating multi-phase and multi-species fluid behaviour (gases and liquids) within the piping system to identify flow patterns, velocity profiles, and areas prone to high wear or corrosion.

- Stress Evaluation: Erosion/Corrosion for both the existing and proposed piping arrangements. This confirmed that the new layout reduced flow induced corrosion and erosion levels to within acceptable limits.

The outcome

By employing CFD, DOCAN successfully completed the analysis and optimised the piping design. The corrosion and erosion for the new piping system was shown to be within allowable limits to ensure that flow-accelerated corrosion was not an issue.

As part of the project DOCAN also provided comprehensive engineering calculations and drawings to enable the client to procure the correct materials, decommission the old system, and implement the new design seamlessly. The result was a safer, more reliable piping system with significantly extended service life.