Projects

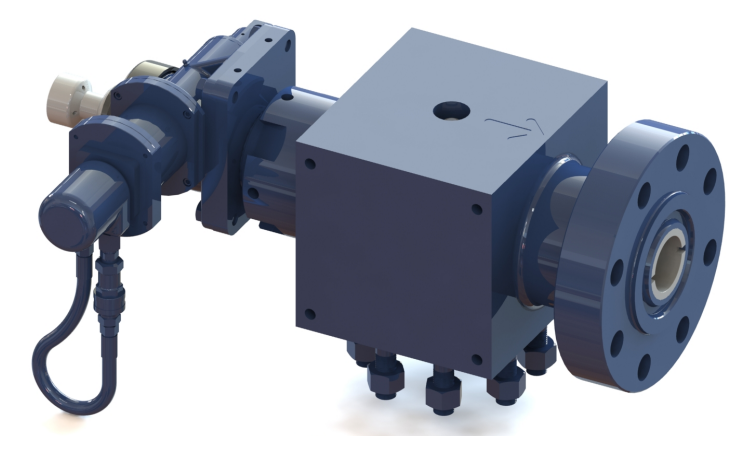

CFD analysis for choke valves in O&G applications

Industry

O&G

Services

Tanks, CFD

Location

USA

The challenge

This project was to determine the flow co-efficient (Cv) curves for two size configurations of a choke. Our client had seen a poor correlation between physical testing and calculations completed by others, and part of this work was for DOCAN to determine the cause of this poor correlation.

The DOCAN solution

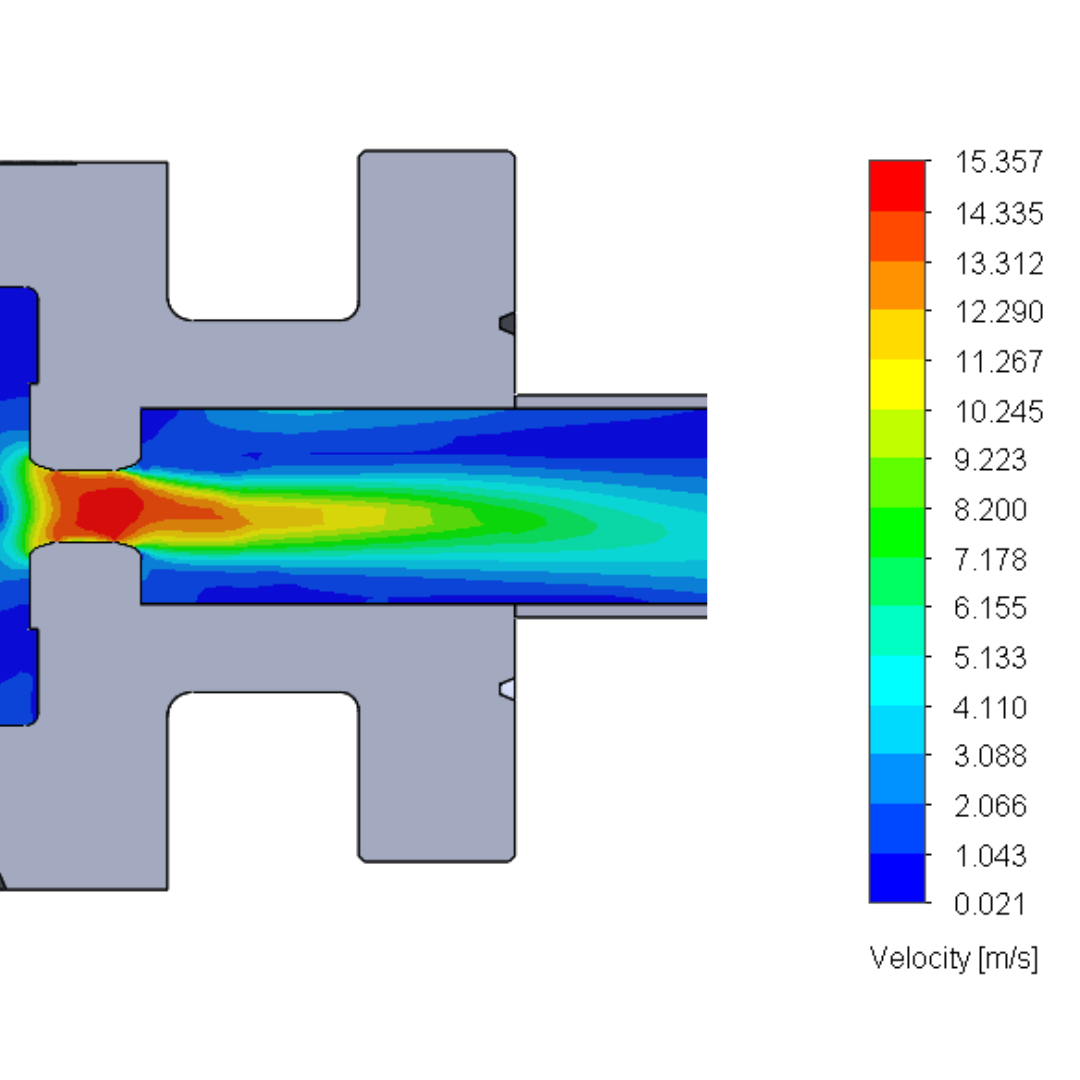

Computational Fluid Dynamics (CFD) was used to determine the pressure drop across the valve at varying stages of valve opening position to then generate the flow co-efficient (Cv) curve data.

Additionally, a review of previous physical test data and calculation work was conducted, to offer an explanation of the poor correlation between the previous calculations and test data.

The outcome

The results presented show good correlation of trends between the flow coefficient (Cv) curves determined from CFD and from physical testing for both valve configurations, however, there appeared to be a discrepancy within the client test data.

The DOCAN results indicated that CFD can be used with a high level of confidence to determine the flow coefficient data for a choke valve, but it is important that any further testing completed should follow a strict QA method to confirm the valve and configuration are correct and traceable.

Project summary

| Task | Application | DOCAN Associate Expertise | CFD | Siemens FloEFD | Health and Safety |

|---|---|---|---|---|---|

| CAD geometry | Build 3D model | ||||

| CFD model building | Modified Parts and Meshing | ||||

| Flow rates & boundary conditions | |||||

| Reporting | Information summary |

Related Inustry & Services

Oil & Gas

Providing full-scope engineering services to the oil & gas industry