Projects

Decommissioning Assessment of a Pressure Vessel

Industry

Oil & Gas

Services

Decommissioning, FEA

Location

UK

DOCAN were contacted to perform a decommissioning assessment of a large +400 tonne, 65m tall pressure vessel to verify its structural integrity before lifting the vessel for maintenance work to be carried out.

The challenge

The pressure vessel had been in operation for decades and due to its scale, ensuring the safety of the lift whilst maintaining integrity of the vessel was paramount.

Our role was to assess the vessel and assist in the planning, preparation and engineering of the lifting activity for safe execution.

The DOCAN solution

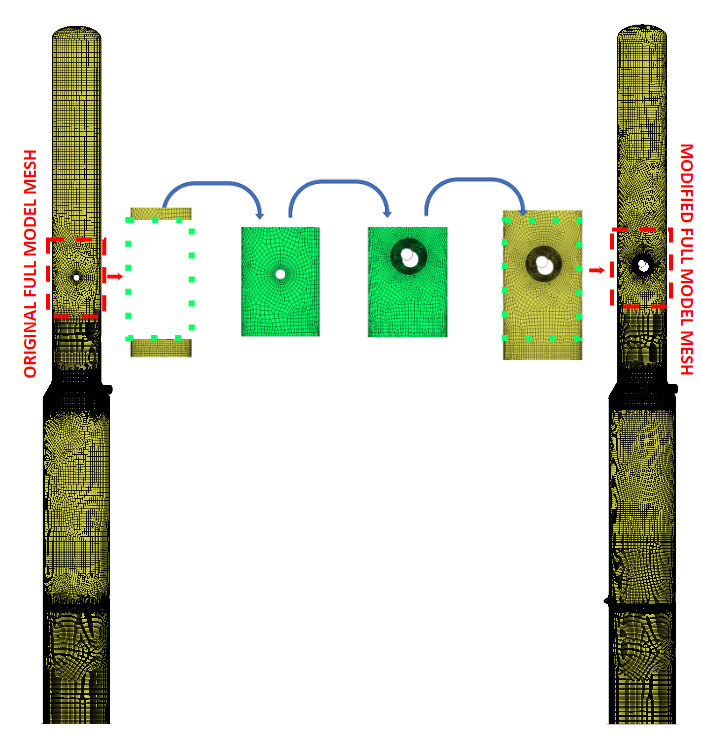

Having previously analyzed and shown this equipment Fit For Service during operation, we had existing Finite Element models of this vessel. As part of DOCAN’s assessment of the lifting of the vessel, historical mesh files were edited to include lifting details.

For the lifting assessment, we needed to refine and adapt several areas of the existing mesh for this pressure vessel FEA model, to analyse the complete vessel.

Once the section of mesh was modified, it was re-connected to the non-linear FEA model, which included large deflection effects, material plasticity, and frictional contact.

The assessment conducted here followed an LFRD (load factor resistance design) method, but the same mesh modelling process could be used if following an ASD (allowable stress design) approach.

The outcome

Through DOCAN’s verification of the vessel and a detailed heavy lift plan, the lift was executed safely and efficiently, allowing maintenance work on the vessel to commence off-site.

This method of working would be applicable to any application where additional load cases or configurations need to be assessed for an existing FEA model, without the original CAD geometry being available.

This is very relevant in industries where heavy engineering and old equipment are to be repaired or decommissioned, such as up and downstream oil & gas, nuclear, and heavy manufacturing.