Projects

FFS Level 1 Assessment

Industry

Software

Services

Postprocessing, Calculation, MAPLE, FEA, DSET

Location

UK, Cheshire

DOCAN had previously worked with a client to repair areas of corrosion on a very large pressure vessel.

The challenge

DOCAN faced many challenges in this project, including assessing over 100 areas of corrosion in an efficient manner according to API 579, requiring detailed knowledge of the code requirements and methodology.

The DOCAN solution

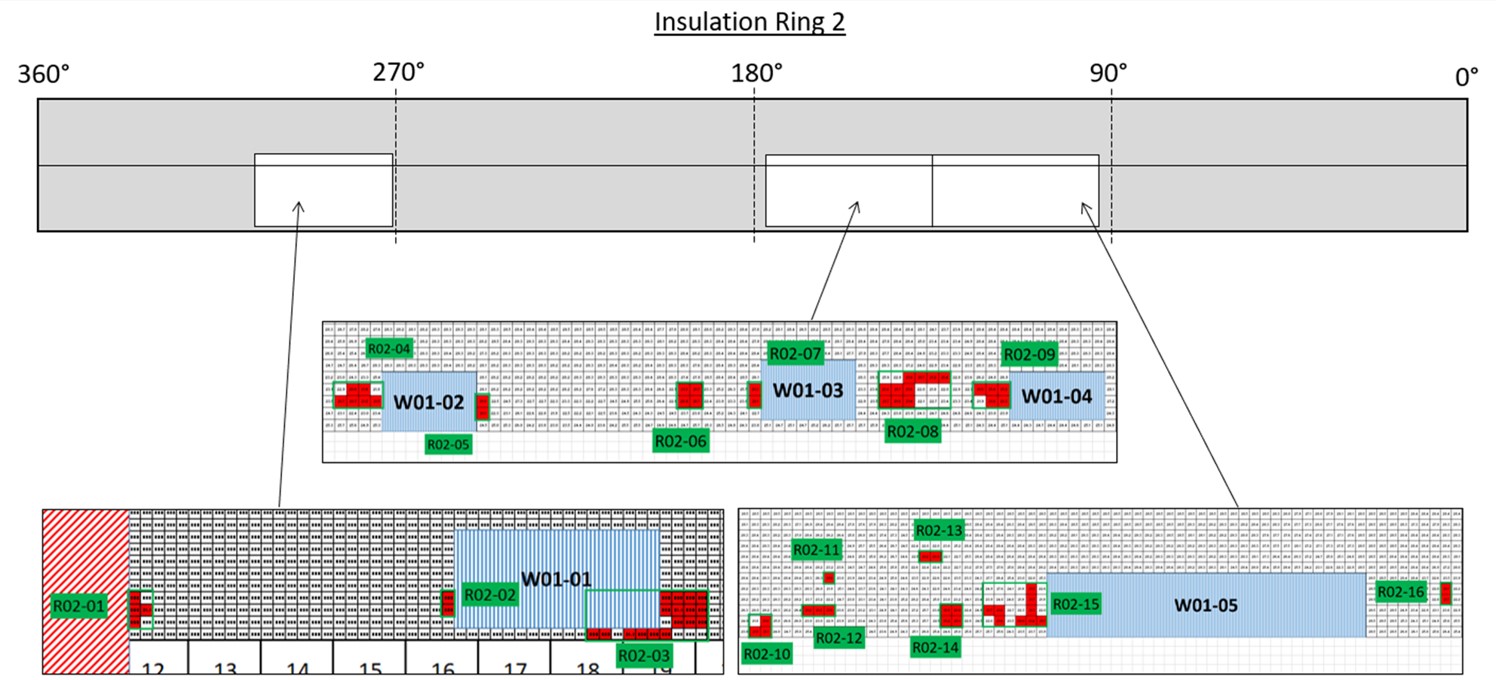

The first stage in the project was to identify the areas of corrosion to be assessed. A screening process was undertaken to identify areas of corrosion previously repaired and determine which of the remaining areas were applicable for assessment. As well as identifying the areas, the size and depth of the corrosion needed to be distinguished from the data available, taking the most conservative values for assessment.

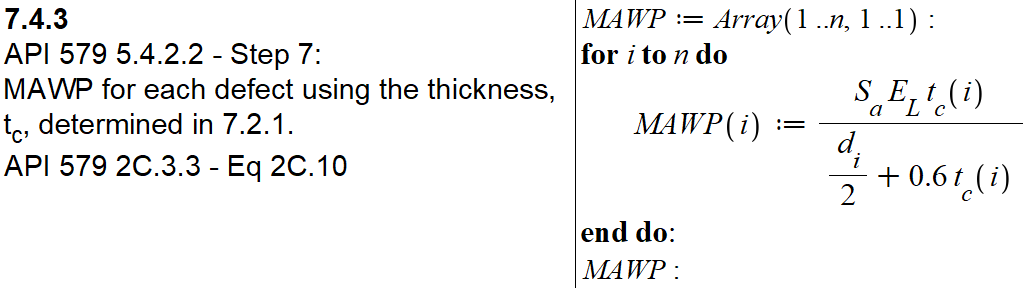

In order to assess over 100 areas of corrosion on the vessel to API 579, rather than assessing each area individually, a Maple calculation was developed to perform the assessment on all corrosion areas simultaneously. The Maple calculation follows the same methodology and process as that described in API 579 and allows all corrosion areas to be assessed in one calculation. Sensitivity studies were also undertaken to determine the effect of future corrosion allowance on the assessment.

The outcome

DOCAN reports offer clear and concise feedback to the client showing the results of the Fitness for Service Assessment.

Project summary

| Task | Application | DOCAN expertise | Pressure Vessels | FFSA | Repairs | DSET | MAPLE |

|---|---|---|---|---|---|---|---|

| Proficiency in use of engineering standards | ASME VIII Div. 1 | ||||||

| API 579 | |||||||

| Engineering calculations | Vessel design code check | ||||||

| Minimum wall thickness | |||||||

| Sensitivity Studies | |||||||

| Fitness For Service Assessment | Level 1 assessment |