Simulation-driven engineering in action: Real-world examples across industries

How we use simulation-driven engineering across a range of industries and projects.

Simulation-driven engineering may just sound like a bit of a buzzword, but it’s actually how we approach a lot of our projects here at DOCAN. It’s a smarter way of solving problems across design, manufacturing and system optimisation.

It incorporates simulation methods like CFD and FEA and puts them at the heart of the engineering process, helping us make better decisions before building physical systems.

We use simulation-driven engineering across a huge range of our projects – from pressure vessels and plant systems to medical models and high-performance seals. In this blog, we’ll walk through some of our real client projects and show how simulation-driven engineering has helped us to not only solve a variety of challenges but also add real value to every stage of the process.

1. Preventing failure in high-pressure systems

When we’re working with systems that operate within high-pressure environments, the cost of any failures can be huge and this applies whether it’s a sealing assemble, a pressure vessel or anything in between.

Simulation plays a key role in designing these systems to prevent failures in the early stages, so we can reduce the risk of costly downtime and repairs. Here are some examples of how we have used simulation-driven engineering for design in high-pressure systems.

Understanding seal behaviour under load

In one project, we carried out a detailed simulation to understand how an O-ring and backing ring assembly would behave under realistic operating conditions. Using material test data from a real elastomer, we built a hyper elastic model in ABAQUS and applied full non-linear analysis.

The goal was to assess how the seal would perform over repeated load cycles – looking at form, fit, and function, and to identify whether it might leak, degrade, or lose effectiveness over time. By modelling deformation, strain, and contact behaviour early in the design process, we could give the client insight into how the seal would behave in real-world situations.

The video below shows logarithmic strains and overall displacements using ABAQUS.

Designing seals with confidence

In another seal design project, we worked with an OEM to develop a new seal where leakage performance, seal ability and IP ratings were critical. The goal behind this was to give them product assurance that the seal would be reliable before it went to manufacturing.

We used ABAQUS FEA to model the product and built a benchmark simulation to analyse how the seal behaved under realistic loads. This included penetration effects, hyper elastic materials, non-linear geometry and loading, and full-contact friction modelling.

By accurately simulating the model, we could verify how the elastomer deforms and how pressure affects sealing contact to verify the products’ performance for the client.

Simulation in pressure vessel design

It’s worth adding that our work in high-pressure, high-temperature systems goes beyond seals. We’re often brought in to support the design and engineering of pressure vessels at all stages of a project from concept to analysis and verification.

Some of our recent work has included:

- Design of multi cell multi-cell multi-elevation resin reactor

- Design of extremely hot rotating calciner

- Moving full process streams from one continent to another

- Design of new massive HP accumulator

- Design review of HPHT heat exchanger

We regularly work to ASME BPVC, UK, and European pressure vessel codes. For Design by Rule (DBR), we combine our in-house expertise with tools like PVElite, CADWorx, and MathCAD. For more complex assessments under Design by Analysis (DBA), we use ANSYS and ABAQUS FEA, often in combination with SolidWorks and DBR checks for a complete picture.

2. Optimising flow and thermal performance in industrial systems

In the case of industrial systems, fluid flow and heat transfer are crucial to performance but they can be challenging to get right. There’s usually a lot happening beneath the surface, whether it’s dealing with thick fluids, mixing fluids, or managing complex heat exchangers but that’s where simulation comes in.

Through simulation, we can get a clear view of what’s going on inside the system so we can solve problems early. Below are some of the recent problems we’ve tackled in this area.

Using CFD to de-risk complex mixing systems

It goes without saying that mixing liquids and gases is typically very complex, and this is what one of our recent projects involves.

We’re using CFD to break the complex challenge down step by step, starting with a benchmark model simulating the interaction between a liquid and a gas, driven by a mixing wheel. Using the Volume of Fluid (VOF) method with buoyancy included, this early-stage simulation helps us understand the core dynamics before building out the full model.

As the project progresses, we’ll be adding exothermic chemical reactions and electromagnetic effects – forming the backbone of a new technology we’re helping to develop.

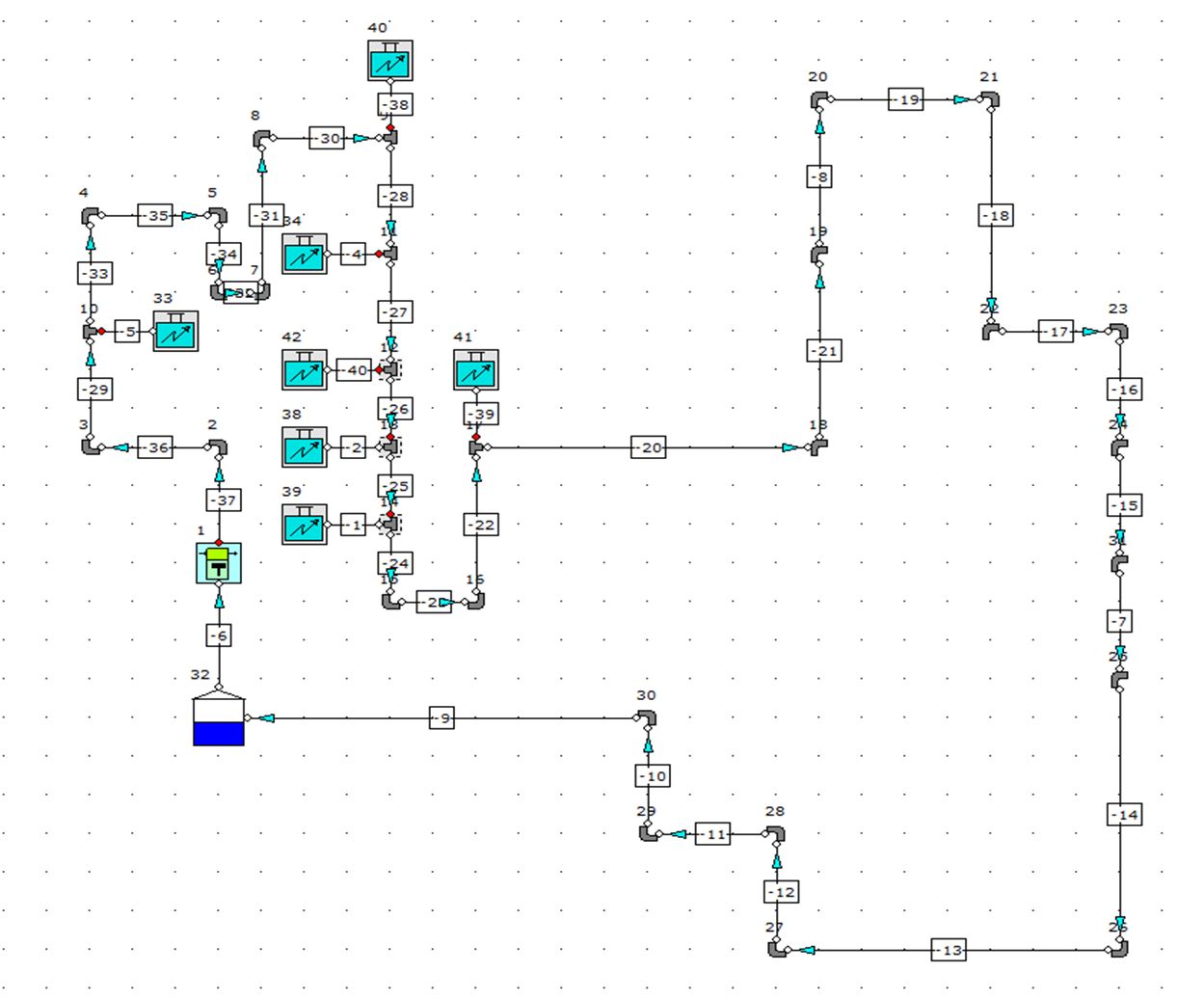

Pumping thick fuel oil across large distances

A recent thermo-fluid project saw us supporting the design of a ring-main system for pumping thick fuel oil over a large distance and large elevation to its multi usage points. Our job was to size both the pump and the main pipeline to ensure efficient flow and to set up the next phase of the project with clarity around cost, time, and performance.

Working at the pre-FEED stage, we focused on modelling the larger elements of the system while simplifying the smaller subsystems. We evaluated different pump types including positive displacement and multi-stage centrifugal considering high flow rates (over 10 kg/s), large elevation changes, and the risk of cavitation.

Using simulation, we identified a positive displacement pump as the most efficient choice and sized the pipework to minimise pressure drops without adding unnecessary cost.

Simulation-first thinking in heat exchanger design

Heat exchangers are critical to many industrial processes and is an area of significant interest and expertise here at DOCAN.

We support both fundamental and codified heat exchanger design, using simulation to solve complex thermal and fluid problems.

Our experience spans everything from 0D and 1D thermal models to full 3D simulations. We work on a wide variety of systems, including internal circuit analysis, fire risk evaluations, and heat and mass transfer scenarios involving chemical reactions.

Simulation lets us test these systems under different load cases, predict how they will respond to upsets, and ensure optimal performance in the design stage.

3. Designing plants and pipelines with precision

When designing complex systems like plants and piping layouts, it’s crucial to make sure they work reliably and efficiently. Things like stress and vibration can have a big impact on performance so we use advanced modelling and simulation tools to make sure every part of the system is designed with purpose.

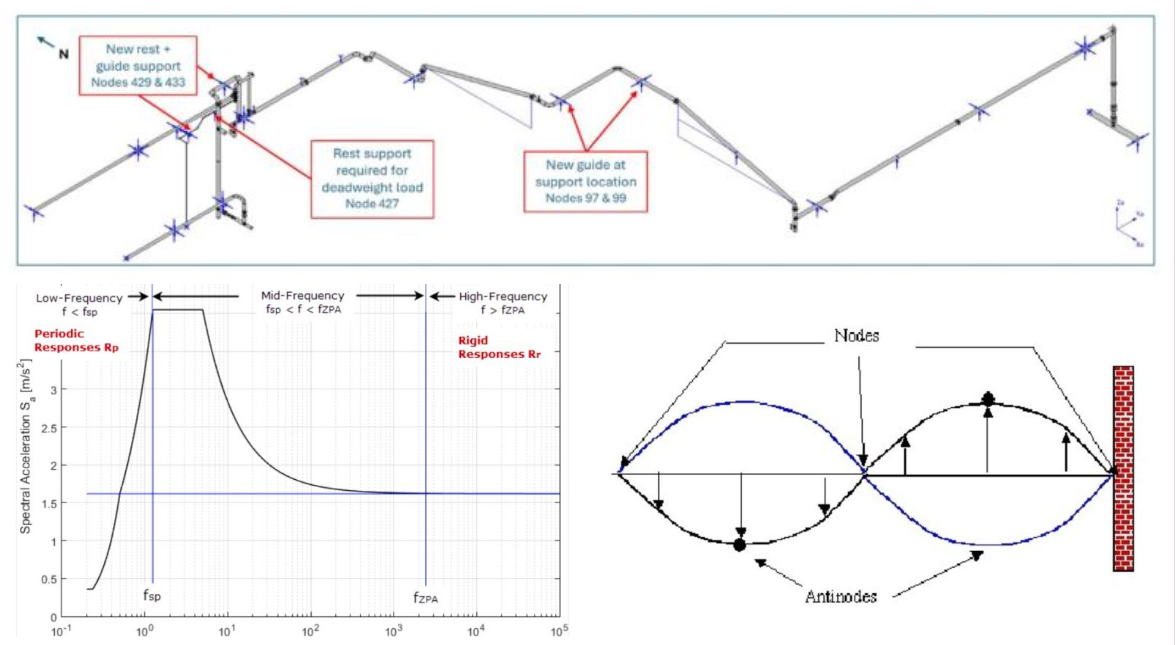

Why natural frequency matters in piping design

We’ve seen it time and time again – pipelines and piping systems are physically installed and operational, but they weren’t truly engineered. One of the most overlooked aspects is dynamic behaviour, particularly the natural frequencies of piping systems.

This becomes especially important in hot or cold systems, where flexibility is needed to avoid stress from thermal expansion. This however, often leads to low natural frequencies – sometimes below 4 Hz – which can be a problem.

If your system is exposed to dynamic loads from pumps, compressors, or machinery, and your natural frequency happens to match those input frequencies, you risk fatigue and vibration issues. Even in seismic zones, poorly tuned systems can experience amplified responses if not properly engineered.

The general rule is to aim for natural frequencies above 4 Hz to keep the system stable under everyday conditions – like valve operations, small vibrations, or environmental effects like wind. The challenge is doing this without over-stiffening the system and introducing new stress concentrations. That’s where smart support placement at the right dynamic nodes or antinodes can make all the difference.

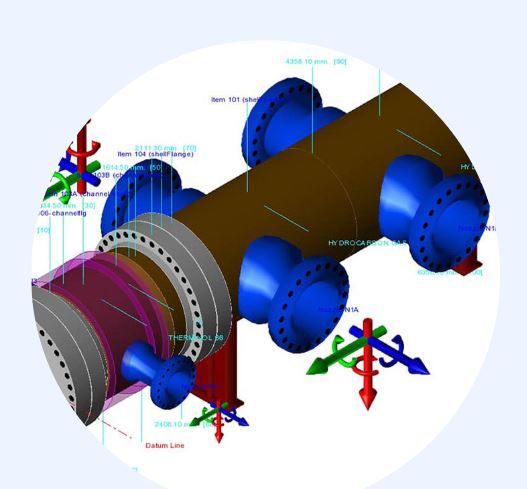

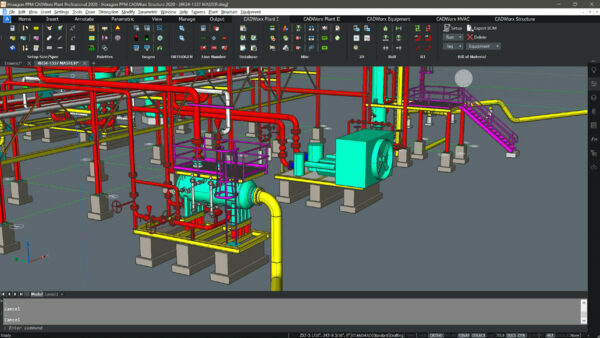

Using CADWorx for smarter plant design

At DOCAN, our engineers and designers bring projects to life through detailed design models and drawings. When working on large, multi-discipline projects, we use CADWorx from Hexagon – a powerful tool that allows multiple team members to work within a shared database model.

On brownfield projects, we link in Leica CloudWorx, which lets us work directly from laser-scanned point cloud data. For larger or more complex projects, we also work with platforms like AVEVA E3D and PDMS.

With CADWorx, we can quickly build out the full scope of a plant including structures, tanks, vessels, piping, equipment, and ECI and start developing construction and deconstruction drawings. The result is a smoother path from concept through FEED and detailed design, with less risk and more confidence from the start of the project.

4. Simulation for niche and emerging applications

Pipelines and pressure vessels might be considered our ‘usual content’ here at DOCAN but simulation-driven engineering goes far beyond these applications.

In fact, some of the most exciting work we’re doing right now is in completely different areas – like modelling human movement, studying explosions and fire scenarios, and looking at how entire systems perform under real-world conditions.

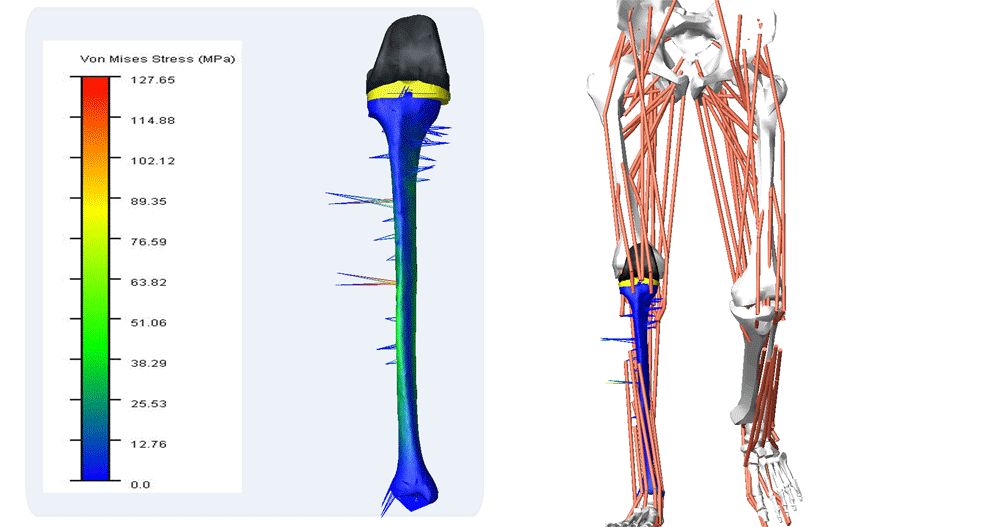

Simulation in biomechanics

We believe every problem has a solution – it just takes time, creativity, and the right approach to find it. At DOCAN, we break complex challenges down into manageable steps before everything starts to fall into place.

Whether it’s advanced kinematics, reactor physics, the design and development of new technology, or simply a complex piping or structural system we deliver. On time, on budget, and with real added value.

Here is a nice example of something out of the ordinary from MSC Adams, used to model human biomechanics, this is one of the most advanced tools available for simulating dynamic systems. So, whether you need support with motion modelling, detailed engineering, or full-system design, our team is here to help.

CFD benefits in various projects

Ever wondered how we help our clients with fluid dynamics challenges? Our work spans a huge range of applications, including:

- Supporting OEMs with static, dynamic, and rotating machine design packages

- Fire, dispersion, and explosion studies

- Green water and splash zone analysis

- Noise and acoustic studies

- Balance of Plant (BOP) and full system or process-wide studies

- Specialist ventilation and HVAC modelling

- Thermo-fluid, chemical, and electromagnetic process studies

And that’s just the start – this area of expertise is growing fast as more clients see the benefits of simulation.

What sets DOCAN apart is that we’re not tied to any specific software or technology provider. We select the best tools for each project, whether it’s ANSYS, ABAQUS, or other leading platforms.

Our engineers and designers working within high-performance quality systems to deliver reliable, first-rate results. With our specialist, multi-disciplinary teams, we can link fluid dynamics studies seamlessly into wider design and engineering projects.

Need help with your project? Get in touch with us to discuss how we can help.