The importance of R&D in product engineering

R&D plays a crucial role in the development of any product, and its accuracy will determine the outcome of the end result.

Turning innovative ideas into successful products isn’t just about creativity, but requires a thoughtful and structured approach. This is where Research and Development (R&D) comes in.

Behind every groundbreaking product or cutting-edge technology, there’s a robust R&D process that lays the foundation for a better-engineered result. Engineering R&D consulting is one of our core services here at DOCAN, and it’s through this very process that we help clients tackle common engineering challenges to deliver them a market-ready solution.

Whether you’re launching a new product or refining an existing one, understanding the impact of R&D can make all the difference when it comes to improving both your processes and end result. In this blog, we’ll share some of our R&D expertise to help bring your engineering projects to life.

Quick links:

What is R&D in engineering?

R&D refers to the processes involved in the conception phase of any product, where essentially there’s an idea for the product but no clear way to take it from concept to a marketable product.

Typically, the R&D stage will involve researching new technologies, testing concepts and refining designs until there’s a tangible solution. With a combination of research, design, and testing it helps us find better ways of engineering products that meet market demands and technical requirements.

When we’re working with a client on the R&D phase of any new product development, our main goal is to guide the design process and verify its integrity. So, our client might have an idea for a product but how feasible is it? How will it operate in the real world? We need to provide them with quantifiable data that will prove feasibility and allow them to proceed to the design stage.

R&D doesn’t just apply to new products though, it’s also applicable when we’re looking to refine and improve existing ones. You’ll see this a lot in essentially any product that has numerous iterations, for example, the latest iPhone. Apple don’t launch a product and then sit still, they’re continuously engaging in R&D to figure out how they can improve their phones to better meet the demands of their customers and stay ahead of their competitors.

From initial research and experimentation to product testing and refinement, there’s a lot that goes into the R&D stage of any product engineering process but arguably, it’s the most important phase.

Why R&D plays an important role in addressing product engineering challenges

Designing and developing a new product isn’t without its challenges but the implementation of proper R&D can help to overcome many of these hurdles from day one, so your project is set up for success.

Let’s take a look at some of the critical challenges we can help to avoid in product engineering.

Challenge: Scope creep

Running into scope creep at some point during the product development process is more common than it should be. This is where the project’s original goals or requirements gradually expand beyond what was originally agreed which can ultimately lead to major project delays.

We’ll usually see this happening when new features or processes are introduced later down the line, without considering how this might impact the project’s timeline. This then translates into delays, cost overruns, and challenges in meeting the initial objectives of the product. Naturally, this is something that any product engineer wants to avoid which is why we’d always ensure that the R&D stage is performed thoroughly and accurately.

How R&D helps to prevent scope creep

Effective R&D involves thorough research and testing that can help to identify any potential challenges which we can address sooner rather than later. For example, if the proposed material proves not to be feasible during the R&D phase we can find a better alternative before money is invested later down the line.

R&D helps to set realistic expectations in terms of timelines, cost implications and product viability, laying out a solid roadmap to follow so that all phases of the project stay on track. Essentially, we can make sure that everyone is on the same page and focused on the project’s core objectives, with any changes being carefully considered along the way.

Challenge: Technical debt

Technical debt can often happen throughout the product development process if shortcuts or compromises are made to meet deadlines, but this can bring a whole host of long-term issues to the table.

Compromises such as using less optimal materials, implementing quick fixes or bypassing testing procedures to speed up development can, over time, create a ‘debt’ which affects the product’s performance and ability to meet goals or standards. This ‘debt’ will eventually need to be repaid which usually means costly and time-consuming fixes, creating even more problems.

How R&D helps to prevent technical debt

R&D helps us to be proactive early on in the process, making sure that product development doesn’t sacrifice long-term quality and performance for short-term gains. In this phase, we can lay down robust design practices and process standards that avoid the pitfalls of quick fixes.

For example, detailed design simulations and process optimisations can reveal any potential integration challenges or scalability issues early, allowing for adjustments that prevent long-term debt. Implementing best practices and comprehensive testing, R&D will ensure that design decisions aren’t just suitable for immediate needs but are also adaptable and scalable for any future requirements.

Challenge: Compliance and regulatory requirements

No matter the product or its purpose, ensuring that it meets all relevant compliance and regulatory requirements is a critical challenge, especially in high-integrity industries. From safety and environmental regulations to industry-specific standards, navigating these requirements can be complex and time-consuming but again, if these aren’t addressed in the first instance this can lead to delays and additional costs later down the line.

How R&D helps to ensure compliance

An effective R&D approach will always consider compliance and regulatory requirements from the very beginning to ensure that everything from the approval process to time-to-market goes without a hitch.

It helps to have a team of experts who understand the specific requirements so they can be worked into the design, testing and development phases, ensuring that all bases are covered. Here at DOCAN, we work with clients across various sectors such as manufacturing, chemical, commercial, medical, oil & gas, and nuclear, and can apply our widespread knowledge of regulatory requirements and compliance across sectors to any project.

Benefits of effective R&D in engineering

When R&D is done right, the benefits it brings to the product engineering process are huge but these might not always be immediately obvious.

We find that when we’re working with a client on the R&D stage of their product development there are many ways we can benefit their project, including:

- Improved product quality: There’s no debate that effective R&D leads to better, more reliable products. When everything is considered from the materials and designs to the operational efficiency, the end result is a product that meets the client’s needs and stands the test of time.

- Faster time-to-market: Product development takes time to get it right, but R&D helps to streamline the process so we can take it from conception to completion within the allotted timeframe with minimal or no setbacks.

- Cost savings: R&D helps to figure out the most optimal materials, production methods and processes from the get-go. Not only does this contribute to improved outcomes but it reduces the risk of mistakes or delays along the way which can lead to further costs incurred.

- Competitive advantage: Effective R&D is a great way for manufacturers to engineer innovative products that keep them ahead of the competition. By gaining insights into the current market and possibly even using tools such as reverse engineering, we can help to improve existing products and open up gaps in the market.

A real-life example of effective R&D in product engineering

DOCAN’s R&D consulting services help clients across a wide range of industries to get their product development processes over the line, offering practical solutions to their engineering challenges and helping them develop products that meet their objectives.

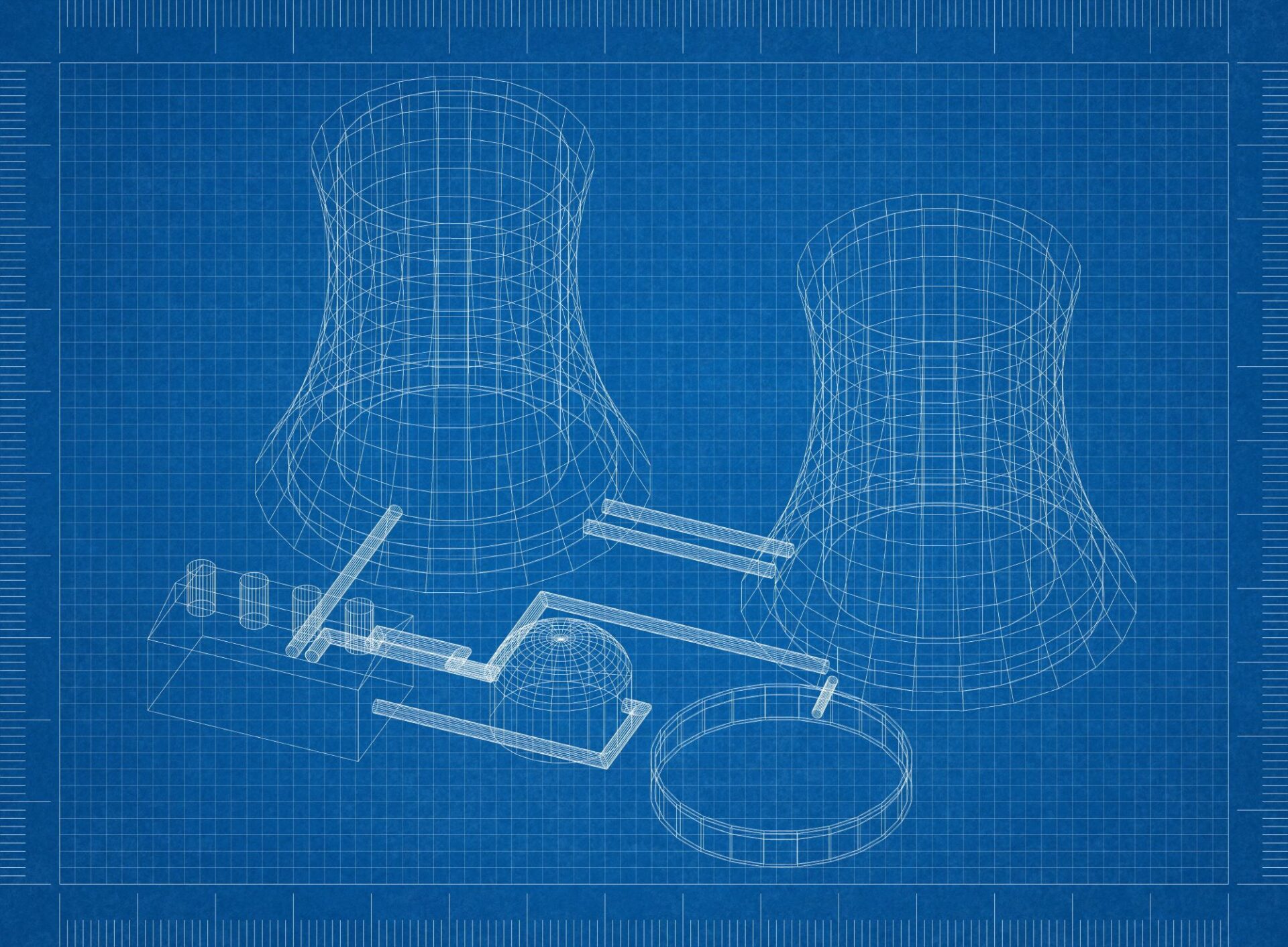

Whilst the nature of our work means that we can’t share details of all the projects we work on, we can disclose information about some including our recent work with MoltexFLEX on their innovative FLEX reactor.

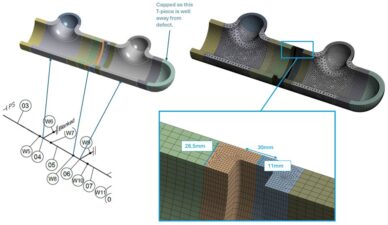

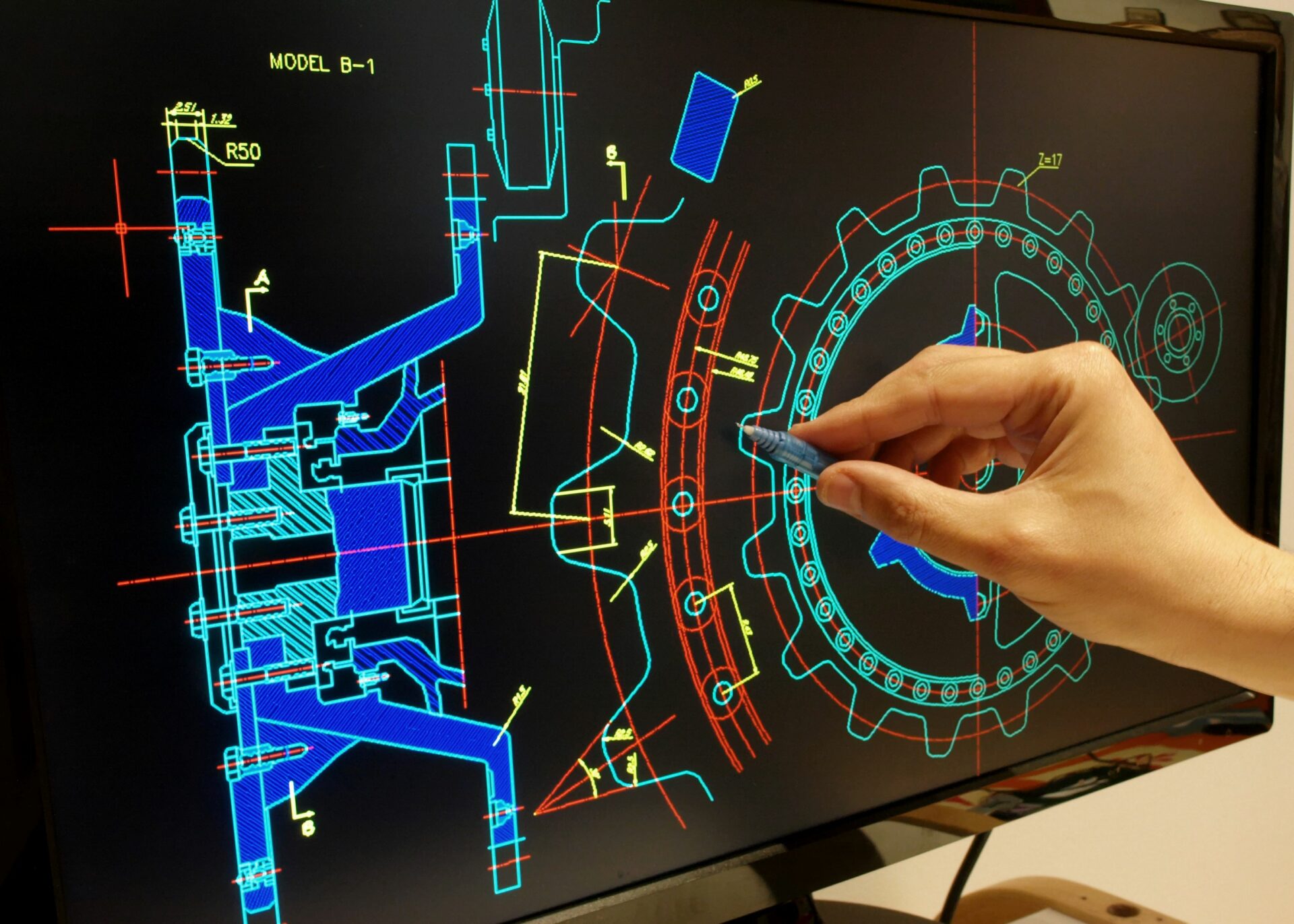

Providing engineering support during the R&D and concept development stages of their new reactor, we offered our expertise in addressing the challenges they had when trying to develop this first-of-a-kind product. Our involvement included offering CAE consultancy and advanced engineering support to help shape viable concept designs.

Using SolidWorks CAD and Abaqus FEA software, we created detailed designs and visualisations of various reactor components. Our expertise in engineering and materials was crucial for selecting suitable materials that meet high integrity standards and ensure long-term durability. Read the full R&D case study.

Above is just an example of how we can help companies overcome hurdles in their product development processes with effective R&D, but we can also offer expertise across the full product lifecycle with advanced services covering many areas of engineering design & assessment and simulation & analysis. If you have a project you’d like some help with, please get in touch with us.