Why vibration analysis matters in defence and aerospace engineering

Vibration is one of the biggest issues that plagues equipment and systems used in the defence and aerospace industries, but we can help to prevent that in many cases.

In defence and aerospace, system reliability isn’t just important – it’s essential. No matter the scale or complexity of the equipment, these systems operate in some of the most extreme environments and under constant stress. That means they need to be robust, durable, and designed to perform in high-stress environments.

At DOCAN, we’ve worked with a wide range of clients across these sectors, from aircraft structures to naval systems, supporting them in solving some of the toughest design challenges. And one of the biggest recurring issues? Vibration.

From the structural loading on aircraft wings to the shaking endured by electronics in a land vehicle, vibration is everywhere. And while it’s easy to think of vibration as a small side effect of movement, it’s one of the most common causes of fatigue, wear, and failure in mechanical systems.

Unchecked vibration can weaken components, reduce performance, and ultimately lead to unexpected failures that can compromise safety and increase downtime. That’s why incorporating vibration analysis early in the design and simulation process is so important.

This blog explores how we can use vibration analysis as a proactive design tool – not just to spot issues, but to design them out entirely.

Why it’s so important in aerospace and defence

The nature of defence and aerospace systems means they’re exposed to more intense conditions than other industries, and there’s no room for error. This doesn’t just apply to large, complex military hardware either, vibration can be found everywhere:

- Aircraft structures experiencing continuous vibration from engines and aerodynamic loads during flight

- Rotating components like jet turbines or helicopter gearboxes operating at high speeds

- Electronics and comms equipment dropped in the field or shaken in transit

- Armoured vehicles enduring constant vibration from rough terrain

- Unmanned drones and small aircraft that must be light, reliable, and durable

- Even field laptops and control systems, which need to keep working no matter the environment

All of these systems need to perform well under pressure and have minimal downtime for any repairs. Vibration analysis helps ensure that we can spot any of these potential problems early to help us improve durability and extend the life of the equipment.

Understanding what vibration is

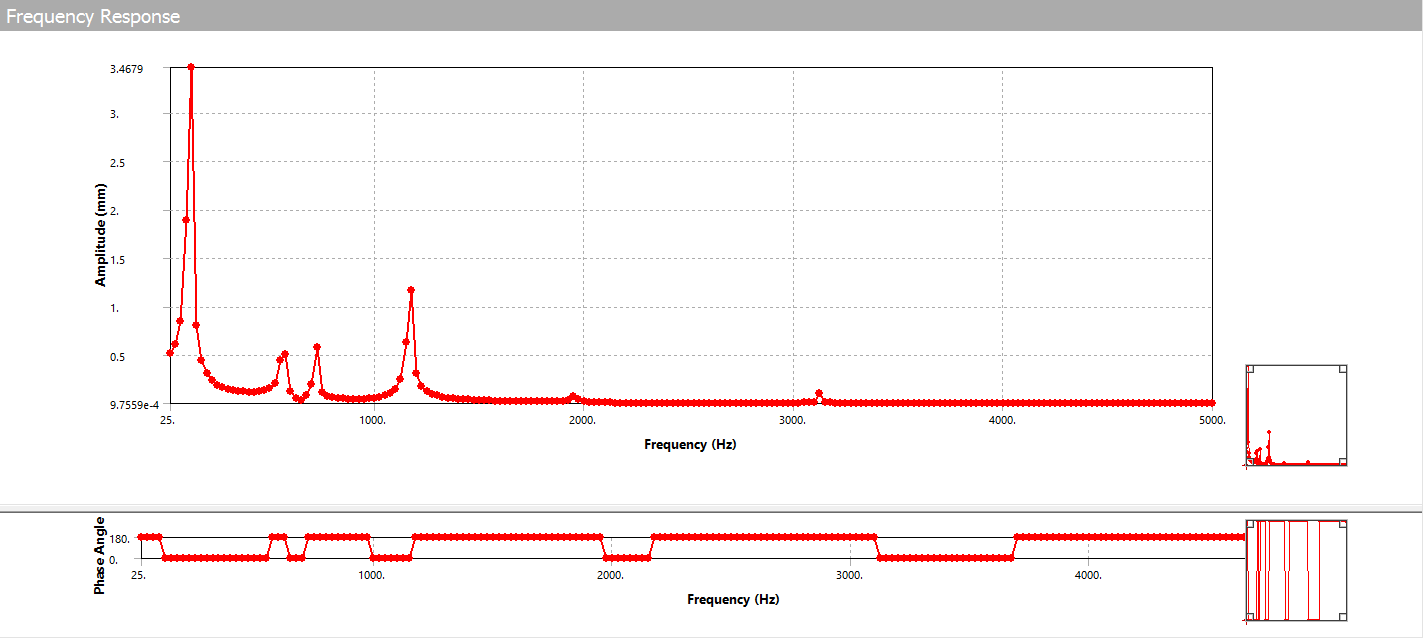

To properly test and analyse vibrations, we need to understand the key factors that define how and why things vibrate. Vibrations are complex and can be described using a few main parameters:

- Amplitude tells us how strong the vibration is. It can be measured in displacement (how far something moves), velocity (how fast it moves), or acceleration (how quickly it changes speed).

- Frequency is the number of vibration cycles that happen every second, measured in Hertz (Hz). Higher frequencies mean faster vibrations.

- Phase shows the timing of the vibration compared to another reference – for example, how two parts of a machine might be moving in sync (or out of sync).

When we’re designing, assessing, or generally working with any vibrating system we’re not just looking at one of these values – we need to analyse them all together to spot patterns and figure out what’s going on.

Some of the main vibration issues to be aware of are:

- Forced vibration happens when something causes a part or system to shake – like the constant running of a motor or the operation of a pump.

- Resonance is when a system vibrates at its own natural frequency. This can be a big problem if that frequency matches the equipment’s operating frequency, leading to much higher and potentially damaging vibration levels.

Designing for effects of vibration

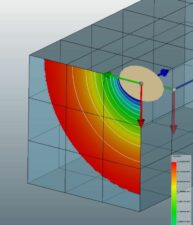

Here’s where smart design comes in. Using tools like FEA (Finite Element Analysis), we can predict how systems will behave under different vibration conditions before they’re even built.

Depending on the situation, we might use:

Modal

Modal analysis is a technique used to determine the vibration characteristics of structures, such as their natural frequencies. This helps us understand how a structure is likely to behave in different scenarios.

Harmonic

A technique to determine the steady-state response of a structure to sinusoidal (harmonic) loads of known frequency. It helps identify steady-state responses and is largely useful in understanding how components will behave under consistent, repeating loads.

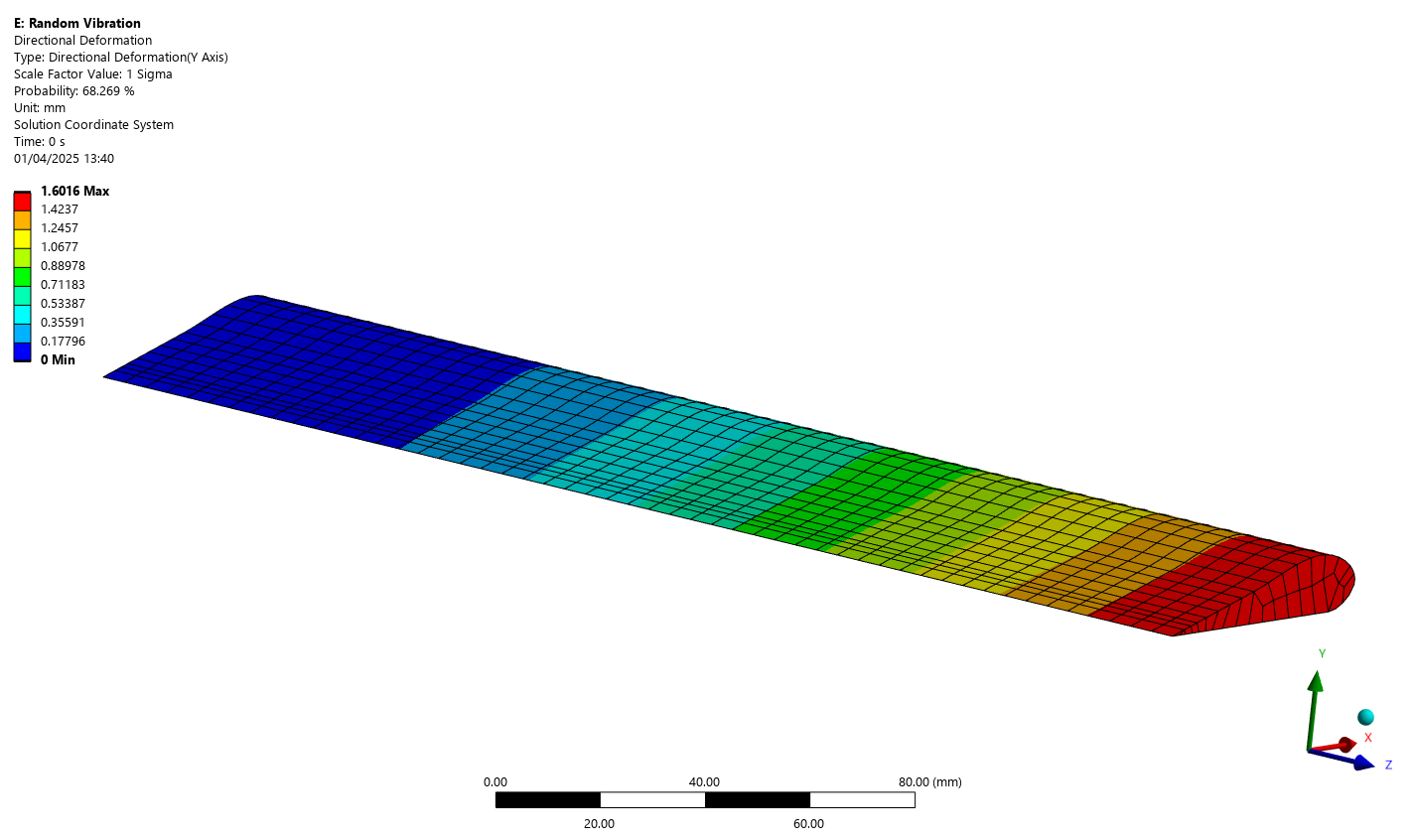

Random vibration

Many common processes result in random vibration where the amplitudes at these frequencies vary randomly with time.

Random excitation can be characterised statistically in terms of a Power Spectral Density plot (or Acceleration Density Plot for structural applications) and can be used in Random Vibration analysis to determine the response of a system to a deterministic excitation.

Time History

Transient structural analyses are needed to evaluate the response of deformable bodies when inertial effects become significant and can handle any type of time-varying load input and are solved in the time domain, giving us the exact response of the physical system.

Response Spectrum

It is common to have large models excited by transient loading. The most accurate solution is to run a long transient analysis; however, we can use Response Spectrum analysis as a quick approximate method that allows for insight into the structural response over many different frequencies without huge amounts of computational effort.

The accuracy of a vibration analysis will depend not only on the type of analysis, but also on how it’s simulated. That’s where choosing between explicit and implicit FEA comes into play.

Implicit FEA is ideal for cases where:

- We are considering quasi-static, or relatively slow speed transient events.

- Our system is inherently stable and well restrained.

- We do not need to consider high speed phenomena, such as shock-loading or stress wave propagation through the system.

Some examples include: constant pressure loading, static forces, slowly applied displacements.

Explicit FEA is typically used when:

- Our system exhibits very high-speed loading events, such as impacts or ballistic strikes.

- There is a high degree of nonlinearity or the system is subject to free body motion.

- We wish to understand the development of stress waves and shock loads and how loads are transmitted through the system.

How vibration analysis is approached makes all the difference. It’s not just about installing sensors and reading graphs, it’s important to understand the whole system and be able to identify what’s normal, what’s not, and what to do when something doesn’t look right.

Measuring vibration on existing systems

It’s one thing to simulate vibration in the design phase, but what about real-life systems that are already in use?

That’s where condition monitoring comes in. We can attach sensors (accelerometers) to key components and track how they vibrate over time. If something starts to drift from its normal pattern, it could be a sign of wear, misalignment, or imbalance and we can catch it early.

A lot of the time, clients don’t even realise vibration is causing problems until something fails. Condition monitoring gives us the insight to spot issues before they get serious.

Read more: What is condition monitoring?

Vibration analysis in problem diagnosis and redesign

Sometimes we’re brought in after something’s already gone wrong – a component fails early, or equipment isn’t performing as expected.

In these cases, vibration analysis becomes a detective tool. We use sensors, simulations, and all the techniques above to get to the root of the problem. Then we help redesign the system to prevent it happening again.

Whether it’s tuning out a resonance frequency, improving damping, or changing materials, we help our clients take what we’ve learned and feed it back into a better design.

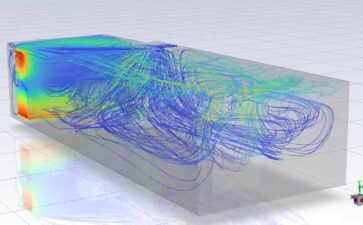

DOCAN’s team of highly experienced consultants and engineers bring deep knowledge of both the equipment and the environments it operates in. Combining vibration analysis with other tools like FEA, fatigue analysis, and CFD to solve complex problems and stop them from recurring.

Whether you’re a major defence contractor or a specialist supplier, we can help you ensure reliability of your equipment. Get in touch with us.