DOCAN’s process engineering consultants offer expert support to clients looking to optimise the design, operation and maintenance of their industrial processes to ensure they run efficiently, safely, and sustainably.

Our process engineering expertise

We have a team of highly experienced engineers with expertise across multiple engineering disciplines such as Mechanical & Piping, Civil & Structural Engineering, Process Safety & Advanced Engineering including Front End Engineering Design (FEED), Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA) and many more.

With a broad range of transferable skills and expertise, we work with clients across a multitude of industries such as manufacturing, renewables, nuclear, oil & gas, energy, chemicals, pharmaceuticals and more, helping them to streamline their operations and ensure their projects are successful.

Our consultancy services span worldwide and we have extensive experience managing projects of all levels of complexity no matter the industry. We work closely with major UK COMAH sites and are experienced in working with various engineering & HSE standards across the globe.

Whether you’re looking for technical support for existing processes or a team to develop new complex infrastructure, we can help. Our process engineering team work with all major standards including API, ASME, BS, EN, DNV, Shell DEP, Saudi Aramco SA, ADNOC and more.

Key capabilities

Some examples of how we’ve helped clients and can help your project include:

-

Pressure relief systems

- Supporting the design, validation and pressure safety valve compliance

- Ensuring compliance with HSE and DSEAR requirements based on API 521 -

Energy & power systems

- Integrity evaluations for steam mains and condensate networks, along with operational support for CHP (Combined Heat and Power) plants

- Conducting energy balance simulations and pressure relief system upgrades for legacy power networks -

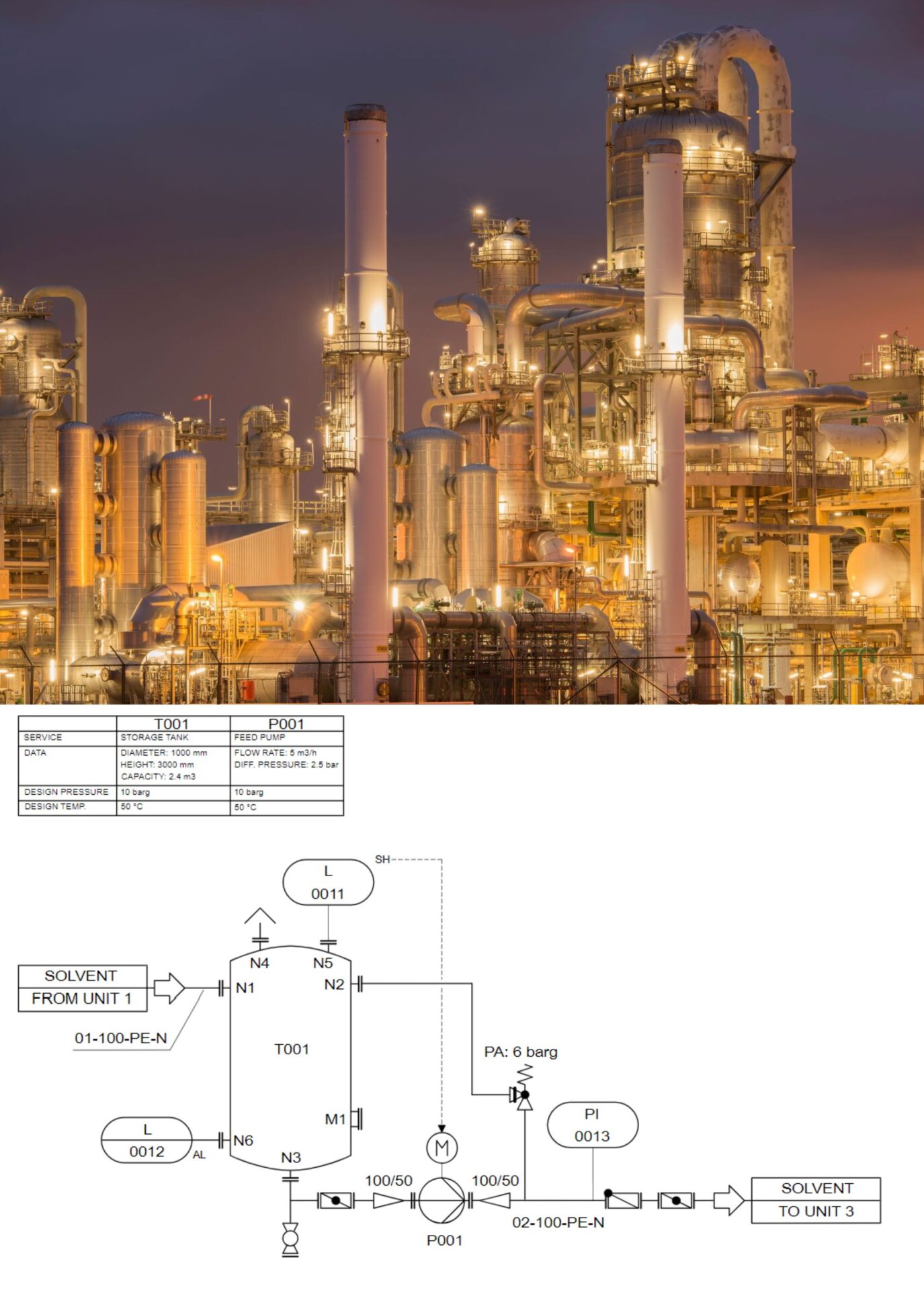

Process Pre-FEED, FEED (Front End Engineering Design), and Design

- Preliminary process design evaluations to establish scope

- FEED including creating P&IDs, mass and energy balances, and defining specifications for equipment and systems

- Design packages including equipment datasheets, process descriptions and design reports -

P&ID preparation & development

- Designing P&ID (Piping and Instrumentation Diagrams) development for new systems

- Optimising process flows in reactor systems, distillation units, and hydrogen supply systems -

Condenser & venting systems

- Design and specification of new condenser systems for solvent vapour recovery and emissions control

- Engineering gas scrubber systems

- IPPC emissions assessments -

Technology & vendor selection

- Assessing and selecting appropriate technology and vendors for new plant installations -

Process hazard and safety assessments

- HAZOP (Hazard and Operability) study

- HAZID (Hazard Identification)

- SIL (Safety Integrity Level)

- DSEAR (Dangerous Substances and Explosive Atmospheres Regulations)

- COMAH (Control of major accident hazards regulations)

- LOPA (Layer of Protection Analysis) -

Process Operational Manuals

- Preparation of Operational Manuals to meet HSE standards -

Process Flow Diagrams

- Preparation of PFDs (Process Flow Diagrams), and equipment specifications -

ISBL & OSBL areas

- Basis of Design for ISBL (Inside Battery Limits) and OSBL (Outside Battery Limits) areas -

Steady state & transient modelling

- Including balance of plant, upset conditions, control optimisation, hydraulic studies and systems characterisation, full 1D & 3D CFD methods, explosion and dispersion modelling and more

How our process engineering services can help your project

The capabilities listed above offer just a small snapshot of what we can bring to your project, but our expertise extends far beyond this.

Our unrivalled experience and deep level of engineering knowledge means we can offer guidance and support in any phase of your project. Whether you need a team of engineers to help design new processes or improve existing ones, we can work with you on your project however and whenever you need us. We pride ourselves on being a cost-effective option for our clients, offering direct access to a team of experienced engineers delivering tangible solutions that fit the brief.

In every project, we always share the same goals as our clients – ensuring smooth project execution and making sure all requirements are met. We have access to many industry-leading software packages and we’ll always use the best tools for the job at hand.

Related Consultancy Services

Info pack

To find out more about our Process Engineering consultancy services, download our info pack.