Consultancy

CFD Consulting Services

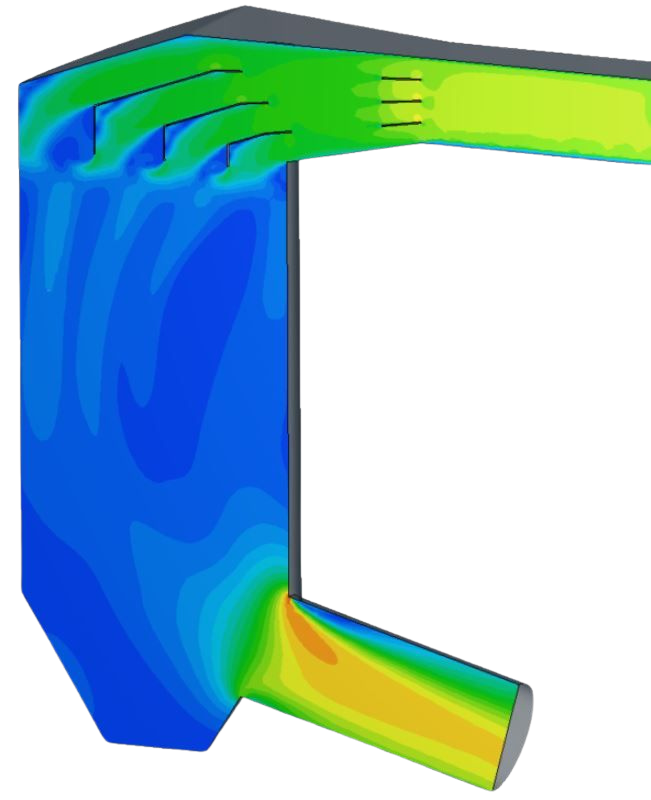

We offer industry-leading Computational Fluid Dynamics (CFD) consultancy services to solve complex engineering problems involving fluid flow and heat transfer on a wide range of applications across industries.

DOCAN's CFD Analysis, Modelling & Simulation Expertise

DOCAN’s engineering team have vast and varied experience in applying state-of-the-art CFD methods to a broad spectrum of complex flow problems across high technology sectors including power generation, oil & gas, petrochemical, manufacturing, aerospace and many more.

With a deep understanding of fluid dynamics, heat transfer, and multiphase flow systems, we offer tailored solutions that address both the performance and safety demands of these industries.

From enhancing the efficiency of HVAC and ventilation systems to optimising battery cooling, fuel cell modelling, and aerodynamic performance, our CFD expertise allows us to predict, refine, and validate designs for a wide range of applications.

Solving Fluid dynamics problems with CFD Simulation

We combine our experience in both the experimental and computation fields of fluid dynamics with world leading software tools to not only analyse and identify flow problems but to devise a fully engineered solution that meets the project requirements.

Our experience in working across a variety of industries and disciplines gives us the knowledge and skillset needed to successfully carry out a CFD consulting project, solving complex CFD simulations no matter the scale.

Our key Computational Fluid Dynamics capabilities

We can apply the CFD method to any fluid flow or heat transfer problem, addressing complex challenges such as multiphase flows, thermal management, equipment design optimisation, energy efficiency, and safety analysis.

Some of the critical areas in which we can help include:

-

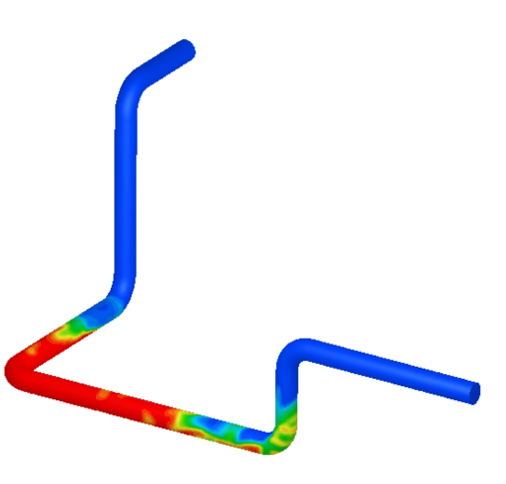

Flow assurance and slug flow modelling

- CFD modelling for complex multiphase flows, including slug flow and flow-induced vibration control to ensure stable pipeline operation

- Flow assurance strategies to prevent pipeline slugging, vibration, and transport instability -

Pressure relief and valve design

- Design and optimisation for pressure relief and choke valves, preventing choked flow and cavitation to improve durability and performance

- Safety analysis for pressure relief systems, enhancing reliability in high-pressure applications -

Fire, smoke, and gas dispersion modelling

- Fire and smoke simulation for safety compliance, with gas and steam dispersion analysis to manage exposure risks

- Radiant heat and flue gas dispersion modelling for environmental safety in oil and gas facilities -

Ventilation and containment systems

- CFD analysis for designing natural and mechanical ventilation in confined, high-risk areas, ensuring smoke control and air quality

- Loss of containment analysis to mitigate hazardous leaks and manage steam or gas releases -

Pump and rotating machinery design

- Cavitation prevention, vibration analysis, and flow management for enhanced pump and rotating machinery performance and longevity

- CFD solutions to reduce wear and optimise flow in rotating machinery systems -

Liquid overfill and containment

- Modelling to prevent liquid overfill and ensure safe containment in storage tanks

- Overflow risk assessment and containment design to manage overfill incidents in oil and gas facilities -

Heat exchanger and turbine flow modelling

- Design and optimisation for cross-flow, double-pipe, and twisted tube heat exchangers

- Gas and oil flow assurance in turbines for reliable energy performance -

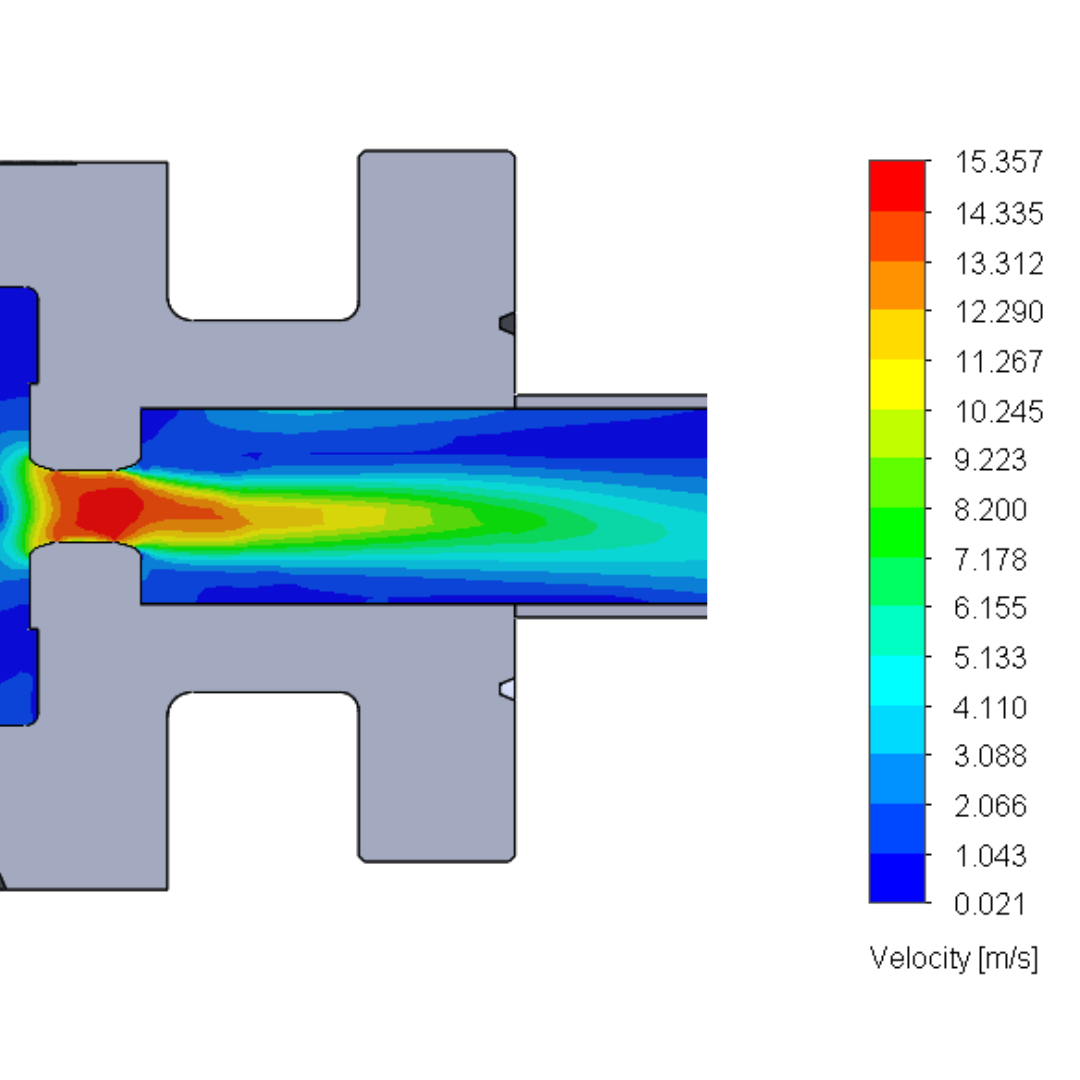

Pipe, valve, and erosion simulation

- CFD simulation for pipe flow, valve performance, and erosion/corrosion in high-stress conditions

- Laminar and turbulent flow modelling to optimise industrial piping networks -

Battery performance and thermal management

- CFD analysis for battery thermal management, reliability, and lifecycle optimisation

- Thermal analysis and simulation to improve battery cooling and performance for automotive and industrial applications -

Heat generation and cooling in electrical systems

- Thermal management solutions for powertrain and underhood components, ensuring efficient heat transfer and cooling

- CFD-based heat transfer analysis to enhance performance in electrical machinery and drive systems

-

Food processing and mixing applications

- CFD modelling and flow control for food processing, improving efficiency in mixing, heat transfer, and quality control

- Customised simulation services for high-rheology materials and food industry applications to enhance process optimisation -

Fuel cells and renewable energy systems

- Fuel cell modelling and simulation to optimise efficiency in hydrogen-powered vehicles and sustainable energy systems

- Integrated thermal and flow management solutions for fuel cells, supporting renewable energy innovations and environmental goals -

Wind farm and wake dynamics modelling

- 3D modelling of onshore and offshore wind farms, optimising energy capture and wake dynamics -

Combustion and chemical kinetics

- Biomass and internal combustion modelling for efficient energy conversion

- Chemical kinetics simulation to support accurate combustion and reaction processes -

Network analysis and clean energy systems

- 1D network and district heating modelling for energy efficiency

- Simulation and optimisation for hydrogen systems in power generation -

Aerodynamics simulation & flow control

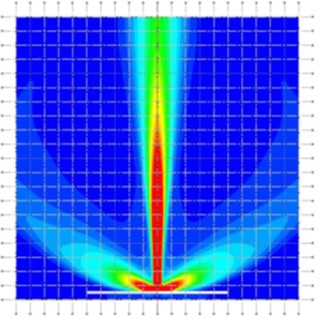

- CFD-based aerodynamic simulation, flow control, and separation analysis for optimised performance

- 3D aerodynamic modelling for vehicles, aircraft, and flow control applications -

Turbomachinery and performance analysis

- CFD analysis and simulation of turbomachinery performance, including compressible and turbulent flows

- Comprehensive modelling to optimise turbomachinery efficiency and flow dynamics -

Combustion and reacting flows

- Simulation of reacting flows and combustion for engines and chemical processes

- Modelling combustion dynamics to solve issues in turbulent and heat transfer scenarios -

Fluid-structure interaction (FSI) analysis

- FSI simulation for dynamic fluid-structure interactions, including axial flows and failure analysis

- Modelling separated flows and structure interactions for design validation and optimisation -

HVAC analysis and optimisation

- CFD simulation and analysis for HVAC systems, including airflow, vibration, and preventative maintenance

- 3D HVAC modelling and airflow balancing to optimise performance and address airflow issues

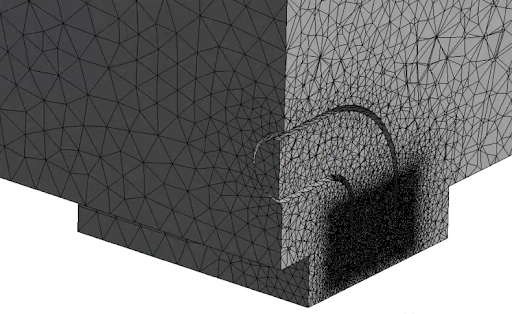

Industry-leading CFD Software

Here at DOCAN, we utilise state-of-the-art CFD software solutions to undertake all consultancy projects which offer a series of practical, industry-leading CFD simulation and visualisation tools. Our CFD tools can incorporate multiphysics co-simulation to achieve couplings with 3D CAD and other relative analysis tools, to improve the accuracy of the simulations.

With our CFD software, we can model effects such as cavitation, aeroelasticity and erosion whether that pertains to equipment, buildings or land. This can be applied to model full HVAC responses, hydroelectric facilities, or piping networks.

Why choose DOCAN’s CFD Consulting Services?

At our core, we’re a team of highly skilled engineers who are focused on solving problems. We analyse, test, provide detailed reports and conclusions, and develop competitive cost-effective solutions that improve product performance and efficiency.

We pride ourselves on our collaborative approach to consultancy work, which sees us integrate as part of your team as opposed to being viewed as an external entity. We share the same goal as our clients and are committed to bringing value to their projects.

As a proud company member of NAFEMS, the international body for engineering analysis & simulation, we strictly adhere to industry best practices through all of our CFD consultancy projects.