Projects

Pipeline Defect Fitness For Service Analysis

Industry

Offshore O&G

Services

Fitness for service, Finite element analysis, Piping, MARC, Calculation

Location

UK - Scotland

A high-pressure pipeline was subject to external corrosion adjacent to a flanged connection. DOCAN were contracted to perform a Fitness For Service Assessment to determine if the defect was safe for continued operation.

The challenge

Due to the proximity of the defect to the flange and the discontinuity effects that this presented, investigation was required prior to undertaking the FFSA to determine how the structural discontinuity affected the stress field around the defect area.

The DOCAN solution

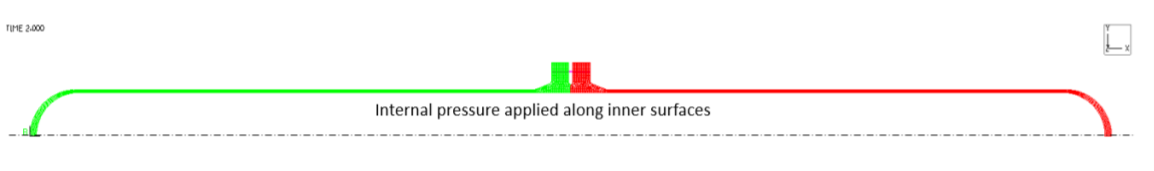

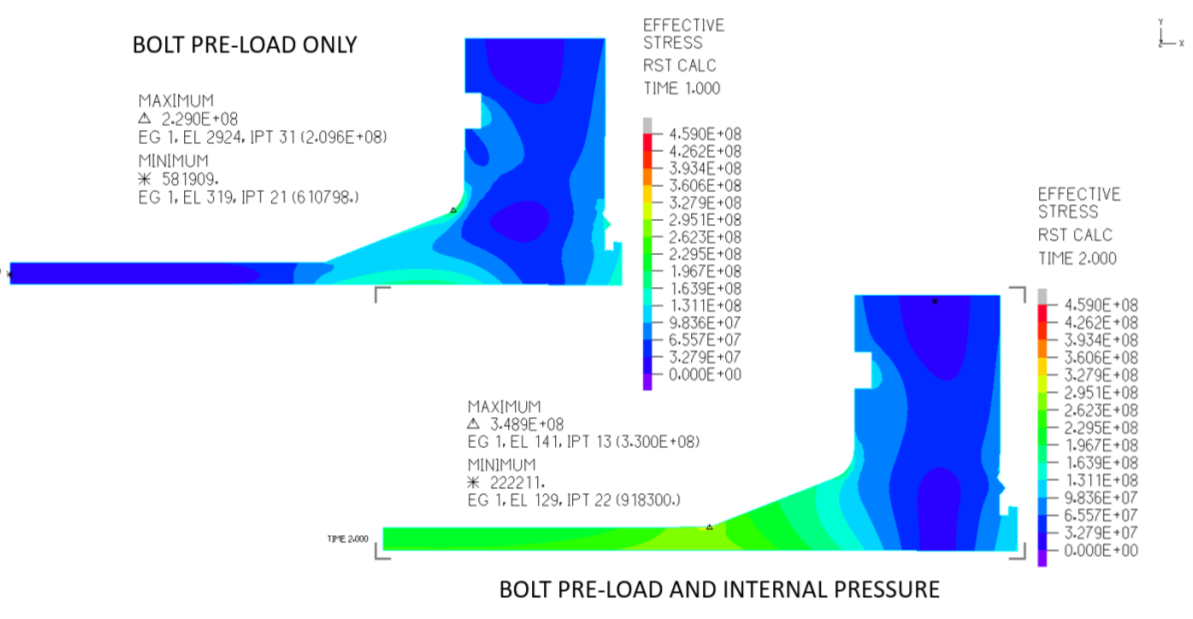

By comparing models of the flanged connection (which included bolt pre-load effects) and a straight length of pipe, it was justified that the flange did not affect stresses in the corroded section of the pipe. The use of CAESAR II pipe stress analysis was also employed to determine the external loading expected on the pipeline, and this was considered in the calculations produced.

The outcome

The formal and verified DOCAN calculations and numerical analyses provided a basis to produce reporting to the client that showed that per the requirements of the relevant codes, their equipment remained fit for service, and they could continue operations.

Project summary

| Task | Application | DOCAN Fitness For Service expertise | Pipe support & piping | Finite Element analysis | MathCAD | MSC MARC | CAESAR II |

|---|---|---|---|---|---|---|---|

| Proficiency in use of engineering standards | DNV-RP-F101 | ||||||

| BS7910-2013 | |||||||

| ASME B31G | |||||||

| PD 8010 | |||||||

| ASME VIII Div 2 | |||||||

| Flange representation | Bolt Preload | ||||||

| ASME B16.47 | |||||||

| Finite Element analysis | Axisymmetric modelling | ||||||

| Bolt representation | |||||||

| Stress linearization |