Thermal shock and flanges: The hidden risks

A real-world case where thermal shock caused bolt bending - and how advanced simulation revealed the root cause.

Some of our projects involve pressure systems operating in extreme environments including high temperatures well within the creep domain. These are not systems you can afford to misunderstand.

In one example, a client experienced new upset conditions and leaks. They wanted to get to the bottom of what was happening and, more importantly, how to mitigate it going forward.

Our approach was to model the full system lifecycle: start-up, various operational stages and sequences, and an aggressive shut-down scenario. This gave us a detailed picture of how the system behaves under stress.

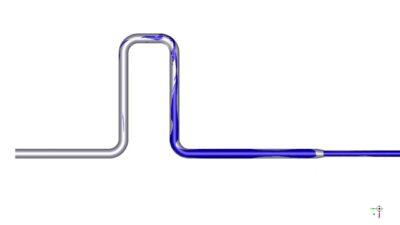

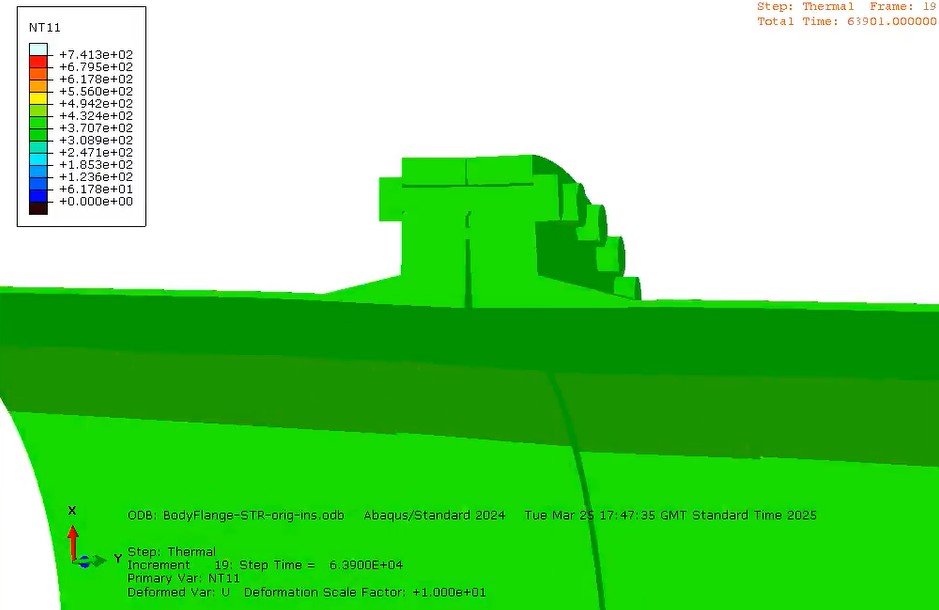

Take a look at the results. On the left, you can see the temperature profile. On the right – stress. One of the key findings? The thermal shock during shutdown causes bending in the flange bolts.

To get these insights, we used ABAQUS FEA – a powerful finite element analysis tool that helps us see what’s really going on beneath the surface.

Understanding thermal shock isn’t just about high temperatures — it’s about how every part of a system responds to rapid changes. And sometimes, the smallest components tell the biggest story.

Need help with understanding how your pressure systems behave under thermal shock or upset conditions? Get in touch with our team.