What is process engineering?

Process engineering for chemical, petrochemical and other industries is a critical service we offer here at DOCAN, here's what it means and why.

Safe and efficient processes are the backbone of many industries, but even more so within the highly regulated sectors of chemical and petrochemical operations. From refining raw materials to optimising workflows, process engineering transforms complex challenges into streamlined, effective solutions.

At DOCAN, we provide expert process engineering services for the chemical, petrochemical, and similar industries. Through innovative techniques and advanced tools, we help clients solve problems, enhance efficiency, and achieve their operational goals. But what exactly is process engineering and why does it matter? Let’s take a closer look.

Quick links:

Understanding process engineering

At its core, process engineering is all about designing, analysing, and improving systems and processes. It’s all about taking raw materials – whether chemicals, gases, or other resources – and transforming them into useful products or services.

Process engineers like ourselves design and improve workflows, ensuring they are optimised for maximum output while minimising waste and energy use. They also ensure safety standards are met to protect both the workforce and the environment. From refining production lines to designing new systems, process engineering is crucial for making complex operations safer, more efficient, and cost-effective.

Our work often involves adhering to critical industry standards, such as:

- UK COMAH regulations for sites handling large quantities of hazardous substances

- API, ASME, and DNV standards for design and operational safety

- Compliance with Shell DEP, Saudi Aramco SA, and ADNOC standards to ensure processes meet the highest international benchmarks

Key areas of process engineering

When we look at process engineering, we need to understand the many unique challenges that they face.

Recognising that they’re extremely fast-paced, demanding and highly regulated sectors that deal with everything from aggressive chemicals and extreme temperatures to stringent environmental and safety standards is crucial for ensuring specialised approaches are in place to meet these demands.

With that being said, let’s take a look at some of the critical areas where process engineering makes a difference in chemical and petrochemical operations.

Pressure relief and safety systems

Safety is paramount in any process, but particularly in highly demanding sectors where pressure relief systems are crucial for preventing dangerous overpressure situations.

With experienced process engineers designing and validating these systems, we can ensure that the equipment can withstand unexpected surges in pressure without causing harm to personnel or equipment. This type of work usually involves selecting the right pressure relief valves and implementing safety measures tailored to the specific hazards of each process.

Energy optimisation

Optimising energy use is critical in reducing operating costs and minimising environmental footprint. By analysing energy flows and integrating renewable energy solutions, we can help to reduce waste, improve heat exchange efficiency, and implement cutting-edge technologies.

The result? Driving cost savings and helping businesses meet sustainability targets by lowering emissions and energy consumption.

Front-End Engineering Design (FEED)

FEED is a vital stage in process engineering that ensures projects are set up for success from the start. During this phase, we can develop detailed plans and strategies that address everything from technical specifications to cost projects.

The goal here is to identify potential risks early, ensure compliance with regulations, and set clear project expectations which lays the groundwork for smooth execution during the design and construction phases.

Process hazard and safety assessments

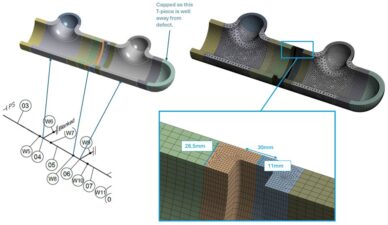

This involves evaluating processes to identify any risks or hazards that could impact safety, operational integrity, or the environment. By conducting rigorous assessments, simulations, and modelling techniques, we can get a good understanding of potential risks upfront.

This enables us to design systems that prevent accidents and comply with industry standards, ensuring both workplace safety and regulatory compliance.

Piping and Instrumentation Design (P&ID)

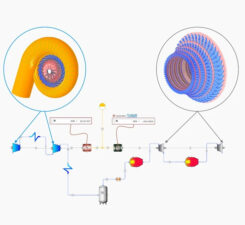

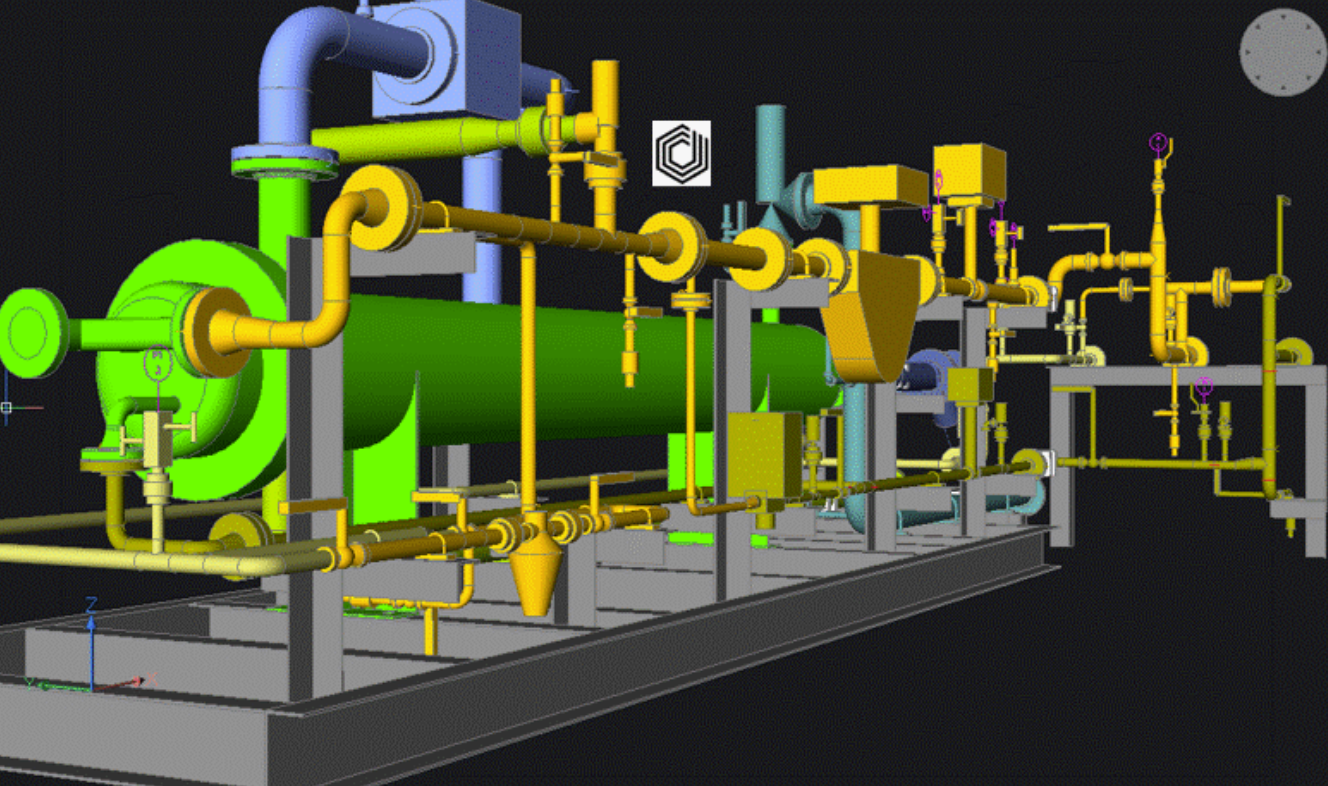

Piping and Instrumentation Diagrams (P&IDs) are key tools in designing safe and efficient process systems.

These diagrams provide a detailed, visual representation of piping, equipment, valves, and control instruments in a plant, helping engineers optimise process flow, monitor system performance, and identify potential bottlenecks or inefficiencies. A well-designed P&ID is crucial for ensuring accurate system installations and smooth operations.

Why is process engineering so important?

Process engineering isn’t just about making things work – it’s about making them work better. It’s the backbone of these industries and for many good reasons, here are just some of them.

- Safety assurance: Process engineers design systems to protect against hazards such as fire, explosion, or chemical leaks, ensuring compliance with global safety standards (e.g., API, ASME, UK COMAH).

- Efficiency and cost reduction: Process engineers streamline workflows and systems, identify inefficiencies, and implement improvements that lead to reduced operational costs, enhanced productivity, and lower energy consumption.

- Environmental compliance: When dealing with strict environmental regulations, process engineers are instrumental in developing systems that reduce emissions, minimise waste, and comply with environmental guidelines.

- Optimising production: Process engineers refine systems to optimise throughput, minimise downtime, and ensure the highest quality outputs, improving profitability.

- Risk management: Identifying potential process hazards and risks is key, and by implementing process hazard analyses we can ensure systems are resilient and operational risks are minimised.

Above all else, it’s important that we strike a balance between efficiency, safety and sustainability within these industries as they are complex and highly regulated, so the goal of process engineering is to create systems that maximise productivity while minimising risks.

How our process engineering expertise can help you

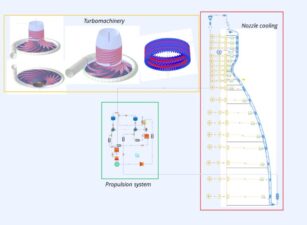

DOCAN’s process engineering team specialises in providing tailored solutions for the chemical and petrochemical industries. With in-depth knowledge of industry standards (such as API, ASME, and UK COMAH) and advanced tools like CFD and FEA, we deliver practical recommendations to enhance your operations.

Solving challenges is what we do best, and this expertise is reflected in our comprehensive reviews of systems and processes. Our services range from FEED analysis to system optimisations and long-term maintenance strategies, ensuring that each project is carried out safely, efficiently, and in compliance with all relevant regulations.

By leveraging tools like advanced thermal and fluid analysis, we can pinpoint areas for improvement and deliver practical recommendations that enhance safety and performance. We don’t believe in one-size-fits-all solutions. Instead, we approach every project with a fresh perspective, adapting our strategies to meet the unique goals of our clients.

From initial design to long-term optimisation, we provide comprehensive support throughout the lifecycle of your project. So, whether you’re looking to improve an existing operation, design a new system, or tackle a technical challenge, we can help. Get in touch with DOCAN today to see what we can do for you.