Projects

Repair drawings for pressure vessel defects

Industry

Oil & Gas

Services

Repair, FFS, Engineering Drawings, Specifications

Location

UK

One of DOCAN’s clients had discovered corrosion under insulation (CUI) around multiple insulation support rings of their pressure vessel that needed repair. Alongside ongoing analysis, DOCAN were designing the repair process and methodology including reinforcement as required and produced repair specifications and drawings for the vessel repair.

The challenge

DOCAN faced many challenges in the project, including working with multiple contractors. DOCAN’s expertise and the experience of its engineers had to be utilized to apply the first principles of the vessel design code to different situations specific to the client’s vessel to ensure the safety of the vessel when undergoing repairs

The repairs required were of large scale and involve disinvestment, sequencing, detailing, parts drawings and reinvestment and was time sensitive to minimise downtime.

The DOCAN solution

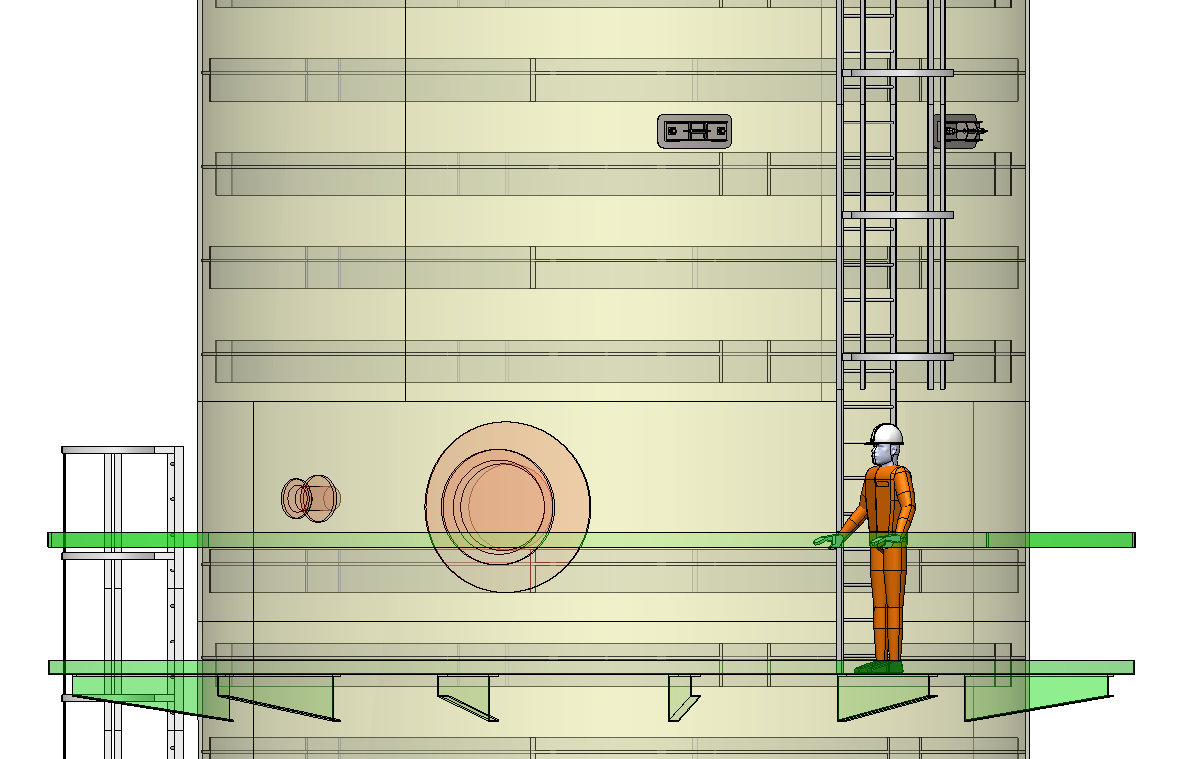

Once information and drawings provided by the client are reviewed, we produced 3D CAD including corroded areas, which greatly assists with visualization and provided the basis of further analyses and drawings.

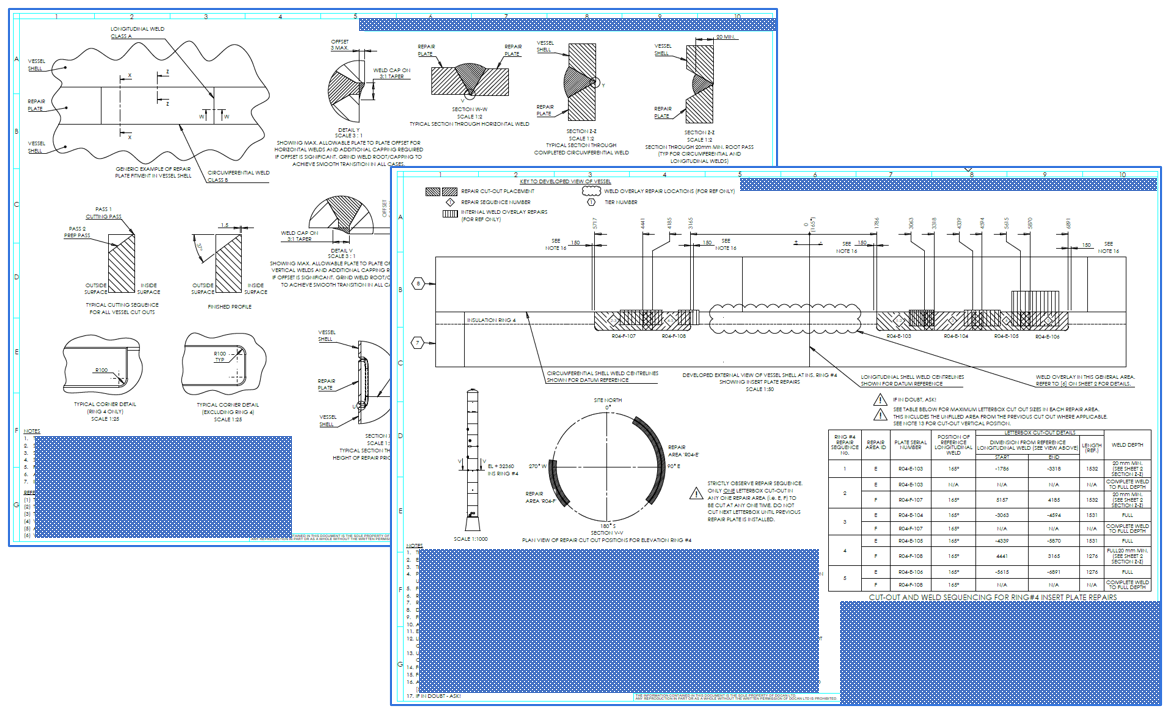

After passing our initial FFS assessment, design of the repair process for the vessel began. The repairs involved cutting and removing sections of the vessel shell to be replaced, as well as individual weld overlay sections to be completed.

Technical drawings were developed using SolidWorks to define the repairs, including all necessary GD&T. A package of drawings were developed including disinvestment, repair and reinvestment.

The outcome

The technical drawing package provided allowed the planned repair of the vessel to be completed successfully by making clear which areas required attention, what operations were required, and what sequence these actions should be conducted in. Accompanying documentation assured the clients of the relevant concerns and solutions involved in the repair process.

Project summary

| Task | Application | DOCAN expertise | Pressure Vessels | FFSA | Repairs | Solidworks | Technical drawings |

|---|---|---|---|---|---|---|---|

| Proficiency in use of engineering standards | ASME VIII Div 1 | ||||||

| ASME VIII Div 2 | |||||||

| API 579 | |||||||

| BS EN 1-4-1991 | |||||||

| API 510 | |||||||

| PCC-2 | |||||||

| Pressure vessel modelling | Wind loading overturn moments | ||||||

| MDMT | |||||||

| Vessel design code check | |||||||

| Minimum wall thickness | |||||||

| CAD modelling | 3D system modelling | ||||||

| Client visualisation | |||||||

| Vessel reinforcement concepting | |||||||

| Virtual Reality walk through | |||||||

| Reviewing stl surface scan data | |||||||

| Fitness For Service Assessment | Level 3 assessment | ||||||

| Linear elastic analysis | |||||||

| Non-linear elastic-plastic collapse | |||||||

| Buckling analysis | |||||||

| Drawings | BS8888 | ||||||

| Repair design | |||||||

| GD&T | |||||||

| Technical drawings | Pressure vessel repair drawings |