Supporting hydrogen projects and developing solutions

An insight into how DOCAN's engineering consulting team support clients on their hydrogen journey.

At DOCAN, we work in many industries, particularly those that are regulated and quite often related to energy.

In this blog, we’ll provide an insight into how we can help with projects where hydrogen is a key element.

Understanding hydrogen

Hydrogen (H) is a colourless, odourless, highly flammable gas, the chemical element of atomic number 1 and in gas form, the molecule is made from two atoms creating the symbol H2.

Hydrogen is the most abundant chemical substance in the universe, constituting roughly 75% of all matter.

Hydrogen has a boiling point of approximately 20K and is generally in gas phase, unless it is at high pressure and in liquid phase (liquified hydrogen). In gas phase, it’s lighter than air and extremely combustible – not so good for hot air balloons.

Hydrogen has a boiling point of approximately 20K and is generally in gas phase, unless it is at high pressure and in liquid phase (liquified hydrogen). In gas phase, it’s lighter than air and extremely combustible – not so good for hot air balloons.

In liquid phase, likely under high pressure and refrigerated or cryogenic, even more risk is present, where gas clouds can form, and double explosions can occur (burnback, secondary explosions, then jet fires).

In liquid phase, likely under high pressure and refrigerated or cryogenic, even more risk is present, where gas clouds can form, and double explosions can occur (burnback, secondary explosions, then jet fires).

Even air products can cool causing secondary fire risk.

Hydrogen-related issues

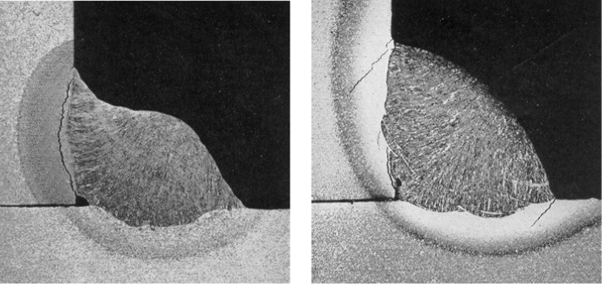

Hydrogen has a tiny molecular size – the smallest in the universe. Subsequently, hydrogen can absorb into steels at room temperature (and is very difficult to seal against, compared to other gases and liquids).

This causes metallurgical issues, such as Hydrogen Induced Cracking (HIC) which is a particular issue in steels, especially high-strength steel, as well as materials such as iron, nickel, cobalt, titanium, and so on.

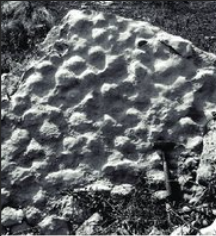

At high concentrations, a hydrogen species can reform into molecules in material voids and cause hydrogen-induced cracking and then blistering. This is a big problem for pressure systems where high concentrations are present, which can form unstable cracks, and blisters can form burst zones as well as further cracks.

When hydrogen is created at the surface of a metal through a chemical reaction, hydrogen can quickly absorb into the metal causing HIC. Typical chemical reaction issues come from poorly controlled electroplating, moist welding rods (causing hydrogen cracking), aqueous corrosion as well as cathodic protection.

To remove hydrogen from chemical reactions, a bakeout method can be employed by heating up the material and letting the hydrogen diffuse out slowly. This is one of the reasons welding rods are kept dry and heated before use (of course following the correct procedure). When this is not done, cracks in welds can occur some time after welding.

Working with different types of hydrogen

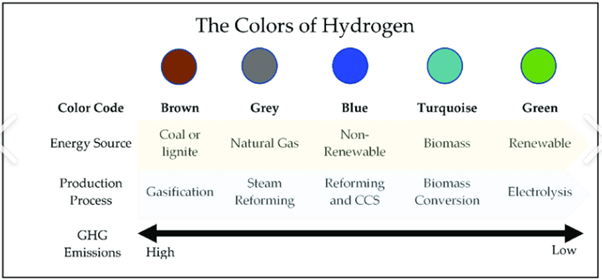

At the moment, there are various colours of hydrogen:

- Green – produced from renewable electrical energy

- Blue – produced from natural gas with carbon capture and storage

- Grey – produced the same as blue but without carbon capture

- Black or brown – produced from coal

- Pink – produced using Nuclear power to electrolyse water

DOCAN have been associated with various colours of hydrogen for both design phases and fitness for service cases, including HIC and Blistering.

We have helped design reactors which will create Pink Hydrogen, and Renewable Energy sources which will help create Green Hydrogen. We have also completed significant work related to Black and Grey Hydrogen.

Hydrogen can be transported in several manners, but typically this is in gas or liquid form. Pipelines are normally used for gas transport, but due to the reasons noted above, Hydrogen is normally mixed with other products such as natural gas to reduce concentration levels and reduce risk – to date, typical hydrogen concentrations are in the order of 5% to 15% – after which risk can significantly increase due to the reasons noted above.

Codes for pipelines and pressurised systems

ASME B31 piping codes cover hydrogen piping and pipeline service with B31.12. Wall thickness calculations, weld details, and fatigue/stress ranging are all variations on the B31 principals but modified to account for hydrogen service particularly accounting for embrittlement effects of hydrogen and fracture.

ASME BPVC Section VIII Div 3 covers high-pressure applications, including the use of hydrogen service with updated rules to account for fracture mechanics and crack growth – particular to the issues associated with hydrogen service.

ASME BPVC Section X covers Fiber Reinforced Plastic Pressure Vessels of several types (types I to V) with various metal/composite/polymer combinations with increasing design pressure, up to 1000 bar.

Our proven expertise

DOCAN have significant experience working with the B31 piping codes, including ASME B31.12. We have also significant experience working with the related pressure vessel codes for high and super high pressure, as well as including fracture, fatigue and crack growth.

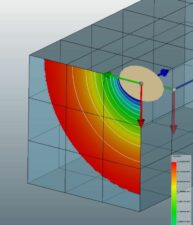

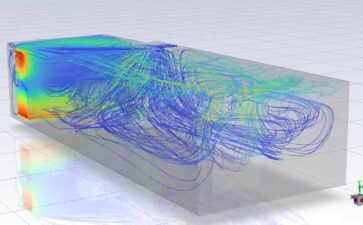

DOCAN have significant experience modelling processes and systems, using 1D to 3D Process and Computational Fluid Dynamics (CFD) and developing overall designs, from FEED to Detailed Designs.

Figure 1 Hydrogen Fuel Cell modelled in Flownex

DOCAN have significant experience in R&D, Design, Modification and Repair as well as Fitness for Service and Decommissioning of Pressure Systems, Structural Systems and Process Safety.

We are also Industrial Members of TWI, VI, and NAFEMS, and also have an annually BSI audited ISO9001:2015 Quality Management System which ensures we deliver high-quality work.

If you are also on the hydrogen journey, get in touch with team DOCAN – we are here to help. Our clients are generally in the UK, USA, ASIA and MENA.

What sets DOCAN apart from the others is our technology-led solutions, our can-do attitude, and our focus on delivery and quality and adding value.