An insight into DOCAN’s Middle East engineering consultancy services

Helping to solve client's complex engineering problems all over the world.

DOCAN is an advanced engineering consultancy and CAE software distribution company based in the UK, with extensive experience and capabilities in providing the same level of service across the world.

Over recent years, our international presence has grown significantly and we have established long-term business partnerships with various companies across a range of sectors in the Middle East.

As we look to connect with other companies across the globe looking for highly skilled consulting engineers to assist with their projects, this blog post gives us an opportunity to introduce ourselves and what we can do for you.

An introduction to DOCAN

We are an established yet continually growing engineering consultancy that prides itself on a can-do attitude and the ability to offer cutting-edge solutions to our clients, no matter where they are in the world.

We are run by experienced chartered engineers, designers and consultants and our expertise lies in working within high-integrity industries including Oil & Gas, Renewables, Nuclear and Manufacturing.

We have a proven track record of delivering on significant safety-critical projects and ensuring that all work is completed in the most cost-effective and timely manner.

Our engineering consultancy services

The core services that we provide cover all key disciplines of highly complex engineering design, assessment, simulation and analysis.

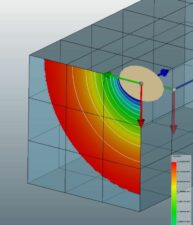

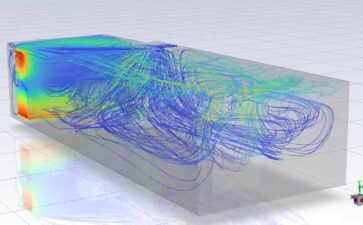

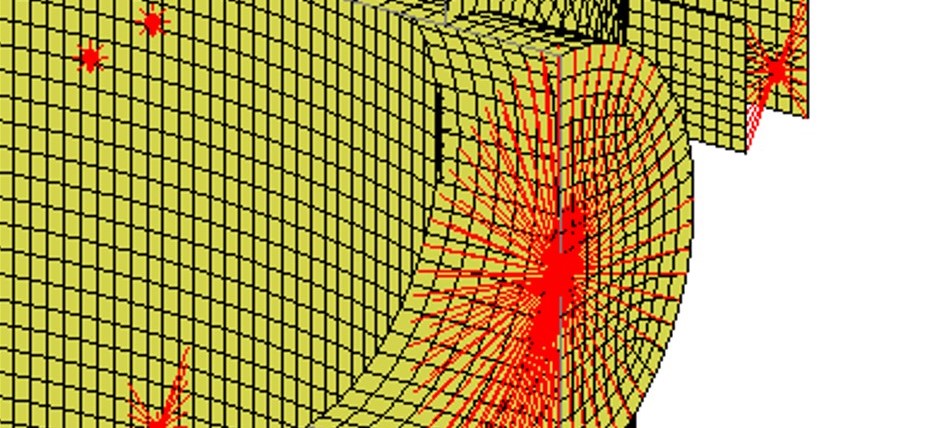

We use design and analysis to provide better engineered solutions, and assist our clients in solving complex problems in the fields of structures, fluid dynamics, thermo-fluids, process, and chemical engineering.

How we help our clients

Essentially, we act as a one-stop shop for providing a complete engineering service. Clients turn to DOCAN when they don’t have the resources or skills in-house to complete a specific aspect of their project.

As an external consulting company, we take the hassle out of managing certain aspects of a project and provide direct access to SQEP (suitably qualified and experienced personnel) resources and high-end software solutions. This eliminates the need for the client to source these themselves, which can often lead to delays in project completion timelines and incur excess expenditure.

Some of our fundamental services within these areas include Fitness for Service Assessments (FFSA) and Decommissioning studies to verify the structural integrity of equipment where safety in lifting, removing or working on existing assets is paramount.

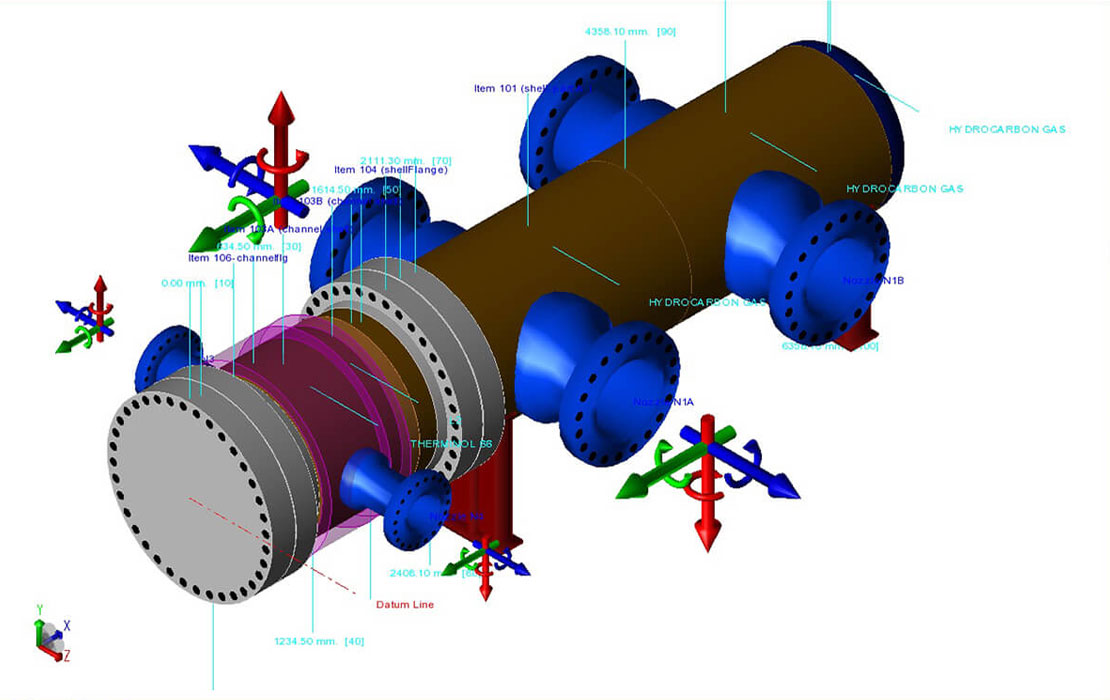

We can provide specialist FEED services to help clients plan, design, execute and improve the efficiency of their engineering projects, and we have particular expertise working with piping and pressure systems. This includes design, engineering and analysis of pressure vessels, pressure systems and piping networks.

Through simulation, we can perform a range of highly complex and in-depth analyses of existing systems or proposed designs through the means of stress analysis, pipe stress analysis, fluid dynamics and 1D systems analysis. As registered distributors of a range of industry-leading software packages, we combine this technology with our experience and expertise to deliver quality-assured and cost-effective solutions to our client’s engineering problems.

Working with an international engineering consultancy

The nature of our services allows us to operate globally, regardless of the location. Whether you’re located in Saudi Arabia or UAE or elsewhere, DOCAN can assist with your comprehensive engineering problems.

We have a proven track record of working with the likes of Uniper, ESSAR and other major global energy companies on a number of projects delivering a wide range of services such as reverse engineering, fluid flow analysis, rerating and pipe stress analysis. We have a demonstrable success rate working on safety-critical Decommissioning projects on tanks and pressure vessels in internationally recognised oil refineries and developing specifications for repair activities.

We’re currently working on several projects at major refineries, as well as multiple other petrochemical sites, reducing their need to source internal engineering resources. Having recently completed FFSA and decommissioning projects on a UK oil refinery for Valero Energy, we received the following feedback:

“As the Reliability & Engineering Leader at the Valero Pembroke refinery I enjoyed a very fruitful technical relationship over the past five years when utilising your team at DOCAN Engineering as an extension of our own Engineering group, particularly for the more complex engineering challenges including fitness for service assessment work to API 579 Level 3. I’m happy for you to share some of the work completed for us including the FFSA and subsequent lifting studies completed for the internal corrosion on our depropaniser vessel 04-F-109 and also the complex engineering work completed around the extensive assessment of the external corrosion on our debutaniser vessel 06-F-101 in addition to the development of the repair strategy for this column completed in our C&O shutdown earlier this year.”

There are many more successful projects we could share, but what’s important is the one thing that they all have in common – the reason why those global companies chose to work with us.

On the face of it, DOCAN is a smaller sized company than your average global organisation but this is one of the driving factors that draws clients to us. Operating on a smaller scale, we take a completely focused approach to each individual project and all clients are prioritised on a personal level. We pride ourselves on the level of care and attention we dedicate to each project and we share the same goal as our clients.

Solving highly complex engineering problems is what we do, and what we’re good at. We’ve refined our skills and services over the years, and our expertise are unparalleled. We recognise that classic EPC is generally done in lower-cost centres compared to the UK, but when it comes to a seriously challenging design and analysis problem at R&D, FEED or detailed design, we have the capabilities to de-bottle the problem and enable the larger project to move forward.

Most importantly, we’re a more effective option than seeking internal resources with the same level of skill and expertise, and we have the flexibility to integrate with your project as much or as little as you need us to.

Learn more about us at ADIPEC

We recently announced that we’ll be exhibiting at the ADIPEC conference in Abu Dhabi this October. This is the next step in growing DOCAN’s reach overseas and we’re excited to continue expanding our business connections in the Middle East.

Find out more about the exhibition here, or if you’d like to hear more about what we can do for your project get in touch with us online.