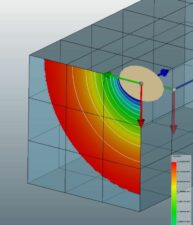

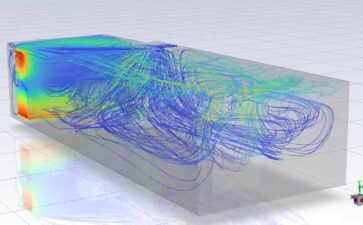

Engineering that has been used to develop carbon capture technology

An insight into the various engineering methods being used to help the UK achieve net zero emissions.

Tackling climate change is a prevalent issue across the globe, and rightly so. In the UK, we’re racing against time to achieve net zero emissions by 2050.

The UK government’s plan has laid out various avenues for achieving this – from banning the sale of petrol and diesel cars by 2030, to reducing emissions and sequestering carbon through environmental means.

Caron dioxide is naturally removed from the atmosphere by trees and green plants through photosynthesis, but it is also absorbed by peatlands. Whilst these processes exist in nature, there are many technologies currently being developed to assist nature and remove excess carbon dioxide from our atmosphere.

In this blog, we take a look at carbon sequestration, what it means, and how engineering is being used to help this process scale up.

Quick links:

What is carbon sequestration?

Carbon sequestration is the process involved in the capture, removal and storage of carbon dioxide. The release of carbon dioxide into the atmosphere significantly contributes to global warming, so the main goal behind sequestration is to stabilise CO2 in a solid form and prevent it from heating the planet further.

Carbon dioxide is released into the atmosphere through both natural processes such as the decomposition of organic matter, and man-made processes such as the burning of fossil fuels. The process of sequestration can be separated into two different forms: biological and geological.

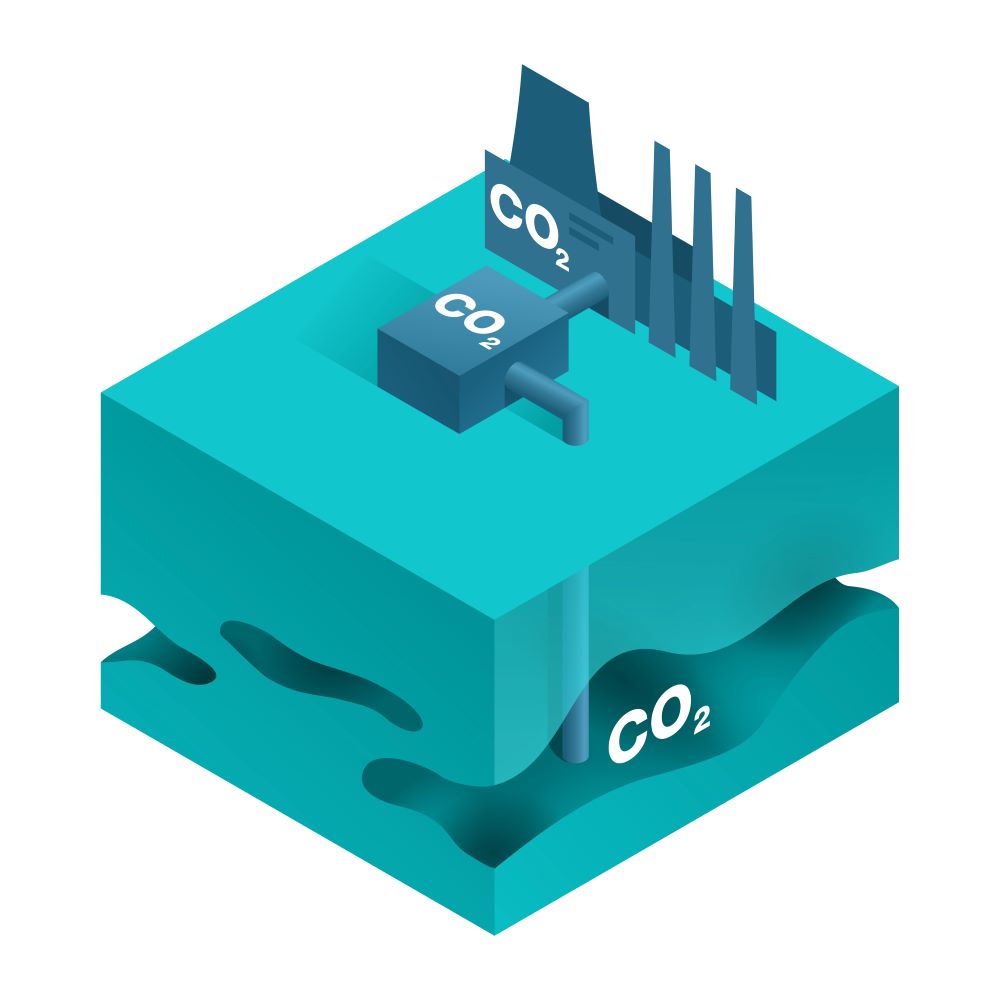

The main difference between the two processes is where the carbon dioxide is stored. In biological sequestration, this is in soil, the ocean, and grasslands and forests. Geological sequestration involves carbon dioxide storage underground or in rocks.

Whilst biological sequestration methods are great absorbers of CO2, when considering the sheer volume of carbon dioxide released into the atmosphere along with threats such as deforestation, this calls on the help of more artificial processes.

These processes sit under the geological umbrella of sequestration and have been developed as a more direct approach to neutralising emissions released by human activities. Naturally, these methods are more technological with a vision to be deployed on larger scales.

Geological carbon sequestration methods include graphene production, engineered molecules, and the main method which we will discuss in this blog, direct air capture technology.

Direct air capture (DAC) technology

Direct air capture is a technology that works to directly pull carbon dioxide out of the air which is then permanently stored underground or reused for other purposes.

Despite the advanced engineering technology that has gone into developing DAC, the methodology behind it remains fairly straightforward. Air from the atmosphere is drawn in through a large fan and into an air contactor. Inside the contactor, plastic surfaces are covered with a non-toxic potassium hydroxide solution. It’s this solution that causes a chemical reaction with the carbon dioxide and traps it, whilst the remaining air passes through.

From there, various advanced technologies have been engineered to stabilise the CO2 in a solid form and safely sequester it underground for long-term storage.

Despite advancements in this technology over recent years, the methodology is relatively new and is continuously undergoing developments to get it to a level where it can be implemented on a large scale across the globe.

From a technology readiness level perspective, DAC technology currently sits at level 6. This means that it’s an advanced engineering-scale prototype model which has been demonstrated but isn’t yet ready for deployment.

This however does mean that there are plenty of opportunities to improve and expand upon the basic engineering structure of DAC, which many global companies are underway with. One of these companies is one of DOCAN’s clients, ORIGEN.

ORIGEN is actively developing technology to extract and store CO2 underground. The company’s technological breakthrough has proven a success in capturing CO2 from lime production methods, demonstrating the ability to manufacture zero-carbon lime.

ORIGEN is working on further expanding this technology to actively remove any existing CO2 from the atmosphere, and store it in deep sea sequestration. This means that the technology has the ability to apply to any manufacturing or industrial process, anywhere.

The large-scale rollout of this technology, and other similar, is an ongoing process but paves the way for a promising carbon-neutral future.