Technology-led plant design services with FEA Tools & NozzlePro

Our plant design services are driven by industry-leading technology to ensure cost-effectiveness and time-effectiveness for our clients.

Over the years DOCAN has been involved in pressure systems of one form and another, using the classic tools.

We extensively use Computer Aided Engineering software and have invested significantly in various technologies such as Ansys and Abaqus (specifically in finite elements) – both of these being world-class solutions.

However, to be cost-effective, time-effective and consistent with industry, we have now invested in FEA Tools and NozzlePro from PRG. This enables us to free up our big hammer solutions for more complex work and use the technology appropriate for the problem.

This gives many opportunities for us and our clients – particularly being cost-effective, and time effective.

FEA Tools

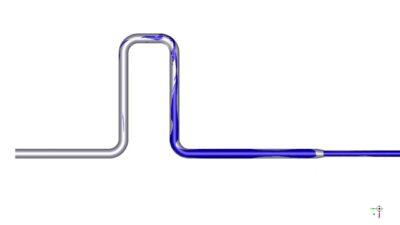

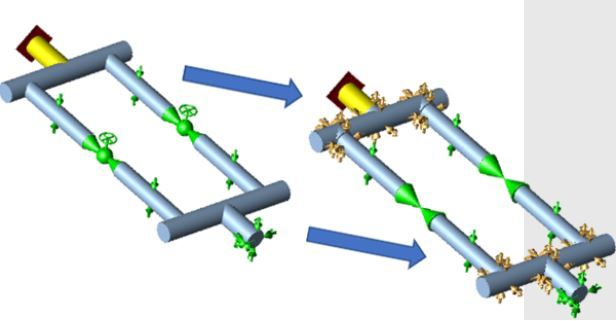

- Conversion of CII pipe stress models to include FEA-generated SIFs and k’s which makes the design more accurate, realistic and optimal

- Design by analysis for piping components such as bends with trunnions

- Finite element mesh creation from beam input pipe model geometry

NozzlePro

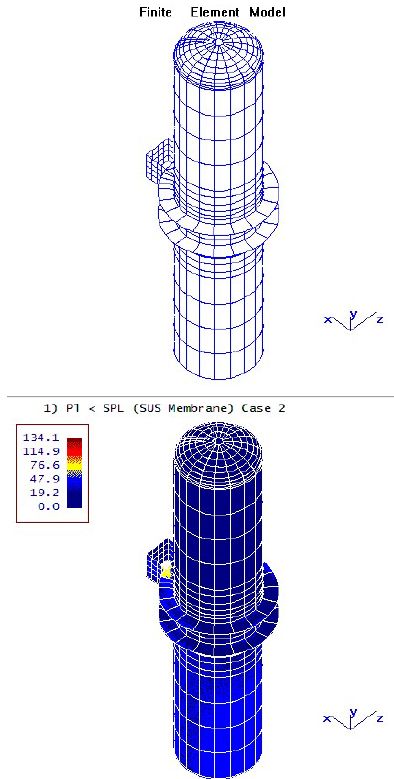

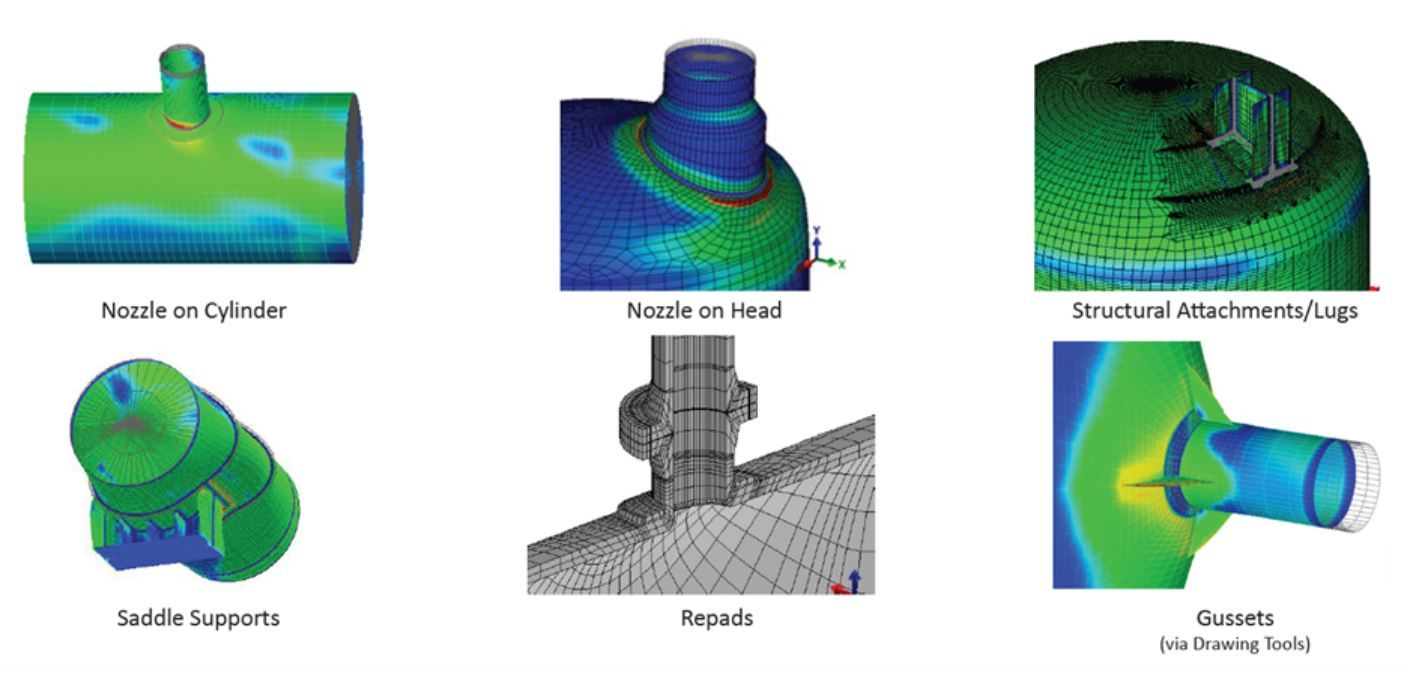

- Rapid FEA of individual pressure vessel and piping components to ASME VIII -Div 2 (static and fatigue)

- Using template-driven input allows complex geometries to be modelled quickly and accurately

- Assessment of geometries not normally within the limits of design by rule codes

- Steady State and Transient Heat Transfer for Axisymmetric 2D Elements

- Local cylinder buckling

- Materials properties database, for the latest code allowable

- API 579 part 3 capabilities

These capabilities are used within our Plant Design Services team as well as our Integrity Engineering Services team.

If you would like to know more about how you can take advantage of our new technology – please get in touch with the team.