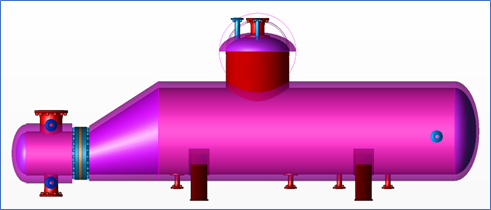

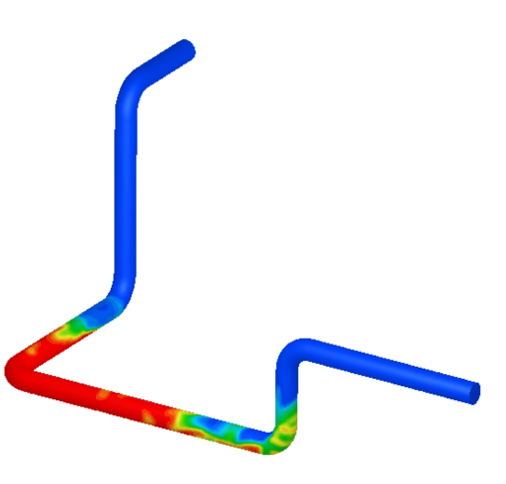

DOCAN’s team of engineers, designers and consultants have extensive experience across the lifecycle of piping networks and pressure systems, offering clients high-level expertise at all stages of their projects.

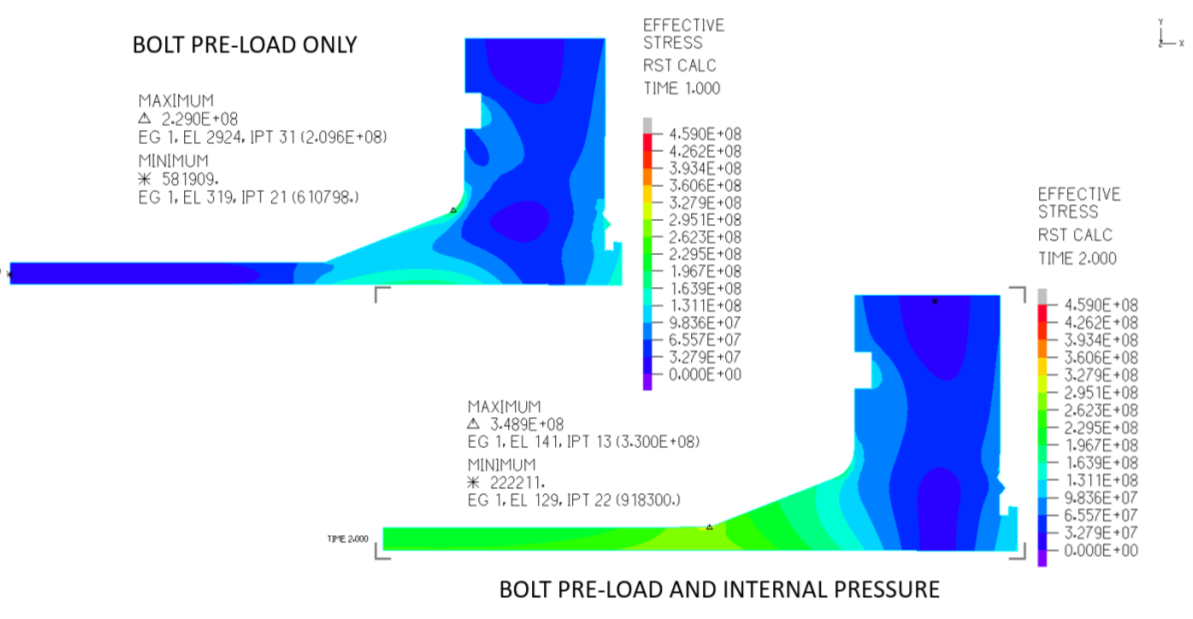

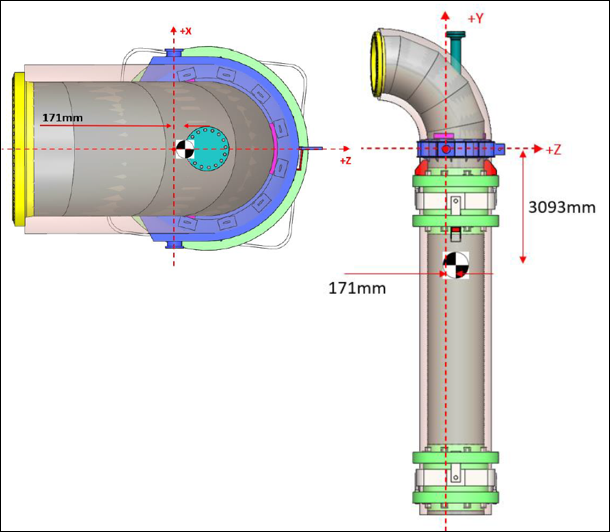

To bring unrivalled value to our client’s projects, we have access to a wide range of pressure systems design software including CAESAR II, ROHR2, PV Elite and TANK.

These software packages offer advanced features for stress analysis, fatigue assessment, thermal expansion, and code compliance checks, allowing us to optimise the design of pressure vessels and piping systems for safety, reliability, and efficiency.