What is finite element analysis (FEA)?

An insight into what finite element analysis (FEA) is and how it is applied across various industries.

Welcome to the latest in our series of introductory level articles, where we aim to cover the various principles, practices and methodologies that make up the field of engineering. Some of our recent articles cover fluid dynamics, structural analysis and pipe stress analysis.

In this article our attention turns to finite element analysis, or FEA for short. We will be taking you through what FEA is, how it is applied across various industries, the history of the method and some of our recent work in this area. It is produced for the general reader looking to educate themselves on the analysis method.

We will cover:

- The finite element method

- What is FEA?

- Applications of Finite Element Analysis

- Our work in Finite Element Analysis

If practical help is what you’re looking for, DOCAN’s FEA consultancy team have extensive experience in solving the most complex engineering challenges. Get in touch with us.

Let’s define the finite element method

In engineering, mathematics is used to help us understand structural behaviour, fluid dynamics, thermal transport and much more.

Most of these processes are described using partial differential equations (PDEs). Numerical techniques have been developed over the last few decades to help computers solve these, one of which is the finite element method.

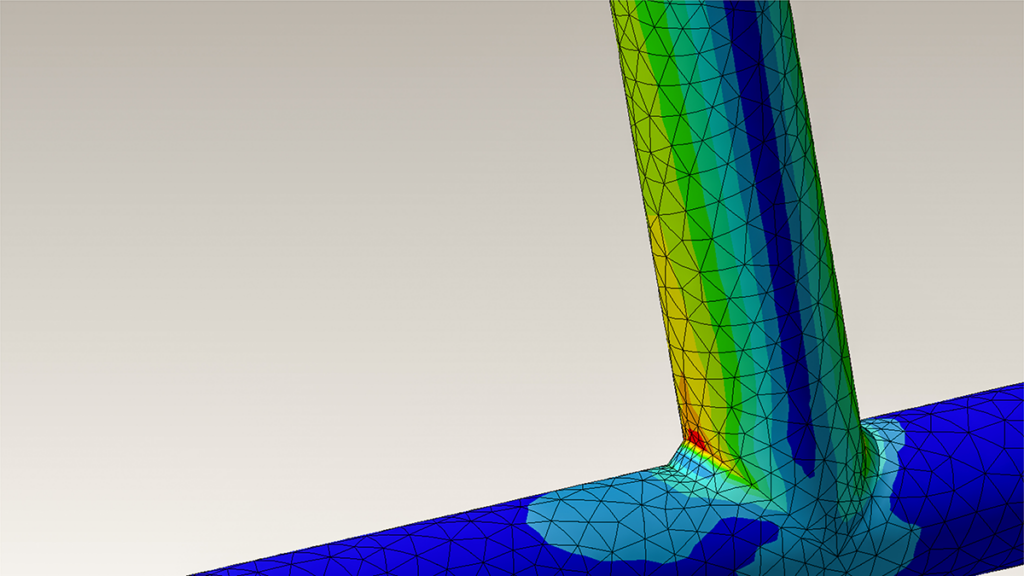

The finite element method (FEM) is a numerical technique used to solve differential equations within engineering and mathematical modelling. To solve an equation, FEM subdivides a large system into smaller and simple parts: these parts are called finite elements, and they are connected together at nodes.

This process is called discretisation, somewhat of a first step toward making a problem suitable for numerical evaluation. The collection of nodes and elements is called the mesh.

For a more detailed description of the method, be sure to watch the video below.

So, what is FEA?

Finite Element Analysis (FEA) is the process of simulating the behaviour of any physical phenomena to understand how it may behave under certain physical conditions, using the finite element method.

FEA can be used when solving various different engineering problems related to fluid dynamics and structural analysis.

Applications of finite element analysis

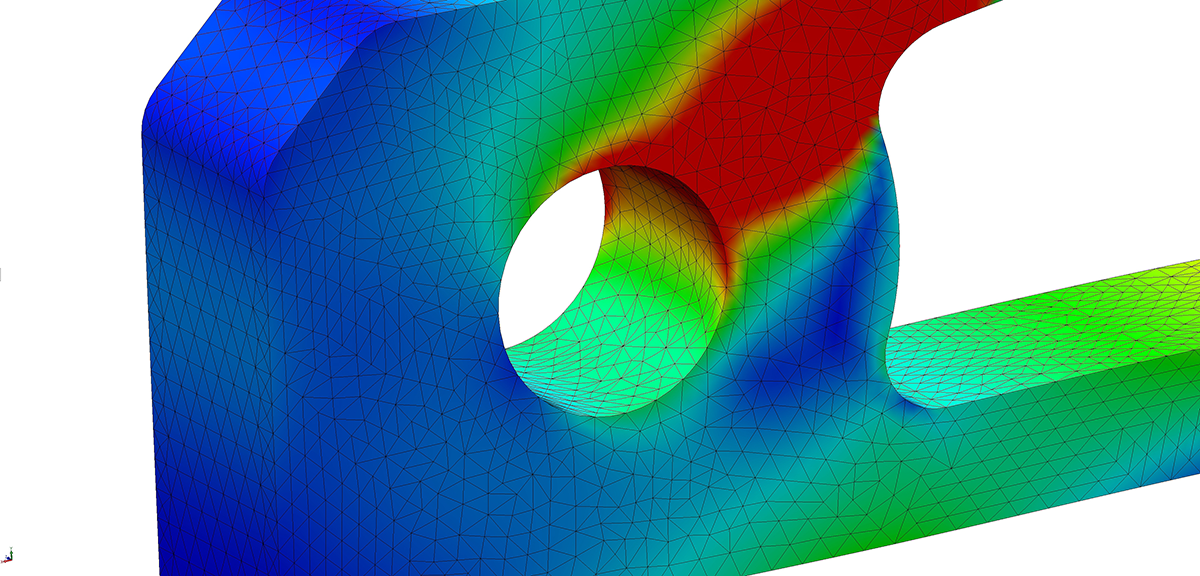

There are a lot of different analytical methods that engineers can use to solve structural mechanics problems, but finite element analysis is often reserved for problems where the geometry, load or materials are too complex to employ manual calculation methods. It is widely used in all major engineering industries and can be used to analyse a wide range of solid mechanics problems including:

- Static

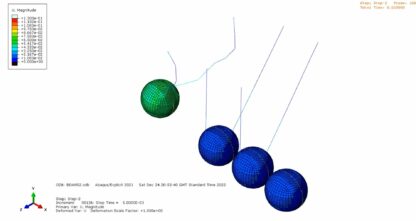

- Dynamic

- Buckling

- Modal analysis

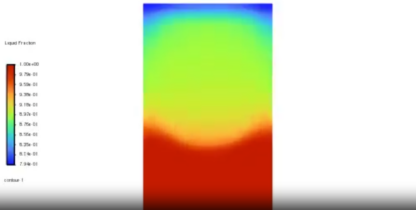

- Fluid flow

- Heat transfer

- Electromagnetic

The finite element method was introduced to civil engineering and aerospace, originally, through the modelling of mechanical applications. More recently we can see applications in fluid-structure problems, bioengineering and biomechanics, and electromagnetics.

Let’s take a real-life example. In the automotive industry, millions are spent every year on safety testing, whereby physical cars loaded with dummies are crashed into structures to analyse the end result. With FEA, automotive companies can create a simulated model of their vehicle and run simulations to determine how it would respond to the crash.

It’s about analysing what a representative model will do when it is met with a specific boundary condition.

Our work in finite element analysis

When a large, +400 Tonne pressure vessel was in need of a safe decommissioning we utilised the MSC Software suite to get the job done. We already have Finite Element models of the vessel prepared, as we had previously analysed and shown the equipment Fit For Service.

For the lifting assessment, we needed to refine and adapt several areas of the existing mesh for this pressure vessel FEA model. Using MSC Apex’s powerful capabilities, historical mesh files were edited to include lifting details as part of our assessment. The lifting analysis and assessment was then conducted using MSC MARC.

For more examples of recent work involving FEA you can read the following project entries:

How DOCAN can help

We have the engineering simulation and analysis tools to get the job done. Our partnerships with fea software developers give us access to a comprehensive range of products and the ability to simulate a huge variety of real-world structures, flows and processes: from simple pipe stress or static finite element solutions to highly non-linear analyses involving fluid-structure interactions.

If you have a brief you can contact us through our website, and we will set up an initial appointment to discuss your requirements in more detail.