What is reverse engineering?

An insight into reverse engineering, how it can be used and why it can be beneficial to engineers looking to reconstruct an object.

Welcome to the latest in our series of monthly articles, where we take a principle or practice from the world of engineering and lay it out in simple terms for the general reader to understand. Today we’re going into detail on reverse engineering, which in essence is the act of taking something apart to see how it works – and then using that knowledge to:

a) Understand the composition of the existing object

b) Update and modify the existing object

c) Engineer something similar

d) Engineer something to a better standard

After this, you may also be interested to read some of our other recent pieces on fluid dynamics and engineering in the oil & gas industry.

For now though, let’s turn our attention to reverse engineering.

Quick links:

First off, let’s define reverse engineering

Strictly speaking, reverse engineering is defined as:

the conceptual reproduction of an object, structure or product following detailed examination of its construction or composition.

Reverse engineering is a common method in furthering one’s understanding of an object, with regard to performing an engineering project on it. The process can also be used to investigate products as part of a commercial market research exercise, but in engineering, it is much more focused on the former.

In mechanical engineering, reverse engineering is often referred to simply as R.E. and it is used to summarise the process of reconstructing an existing object. Engineers will use computer-aided design tools and techniques to draw up a specification and produce drawings from which the item is constructed.

The stages of the reverse engineering process

There are three key stages within the reverse engineering process. Let’s run through them below.

1. Information extraction

Existing documentation, research and even press can be browsed and analysed in detail to learn as much as possible about the object. This leg of work is all about establishing as much context as possible, ensuring that the composition of the object is made as clear as possible. It is a vitally important part of the process as it ensures that all future learnings are contextualised, and it also helps pick up a few extra pieces of information along the way.

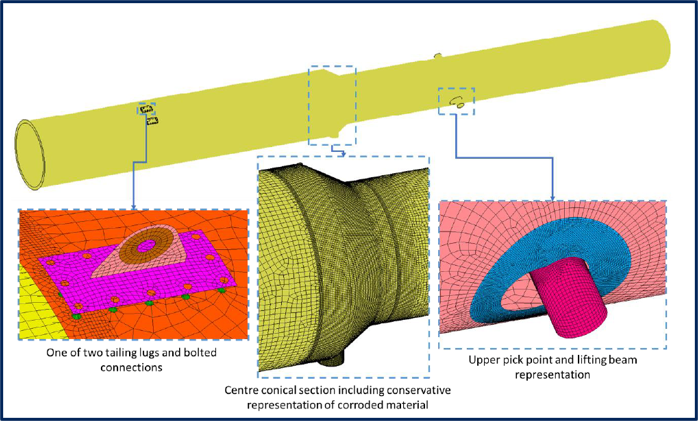

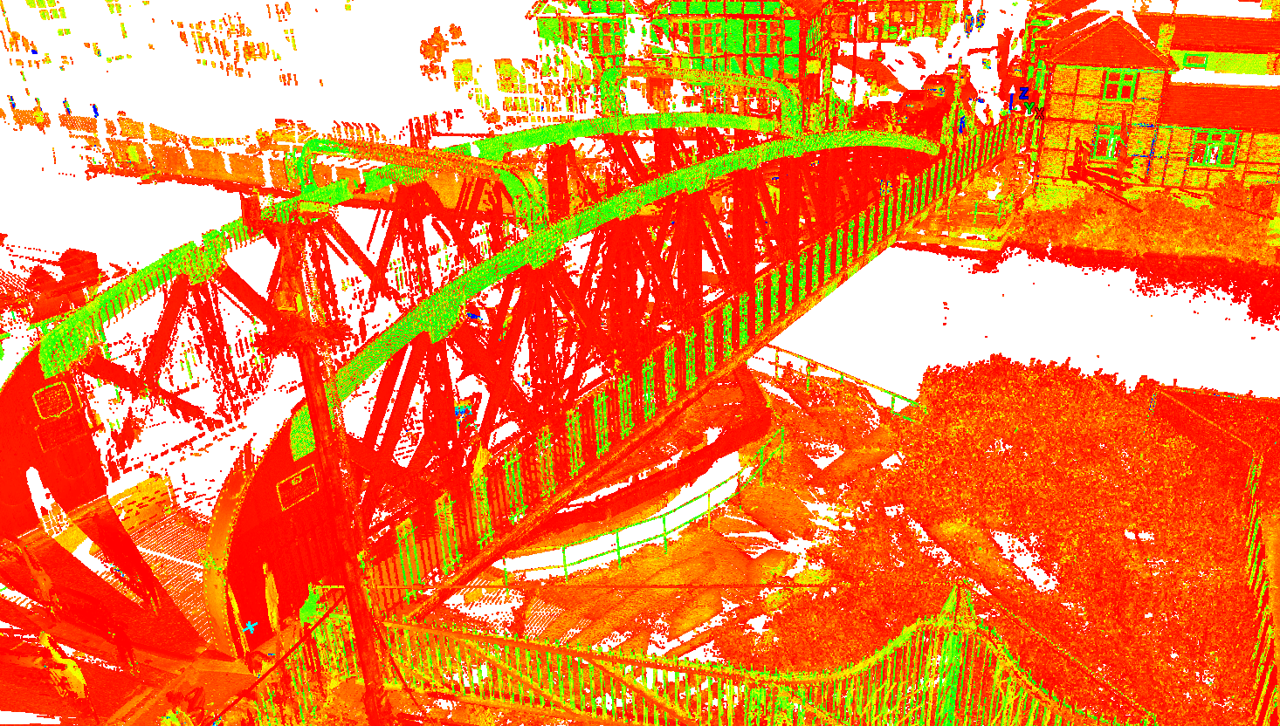

It is at this stage that engineers would look to perform a variety of tasks to help assess the existing object. This can include 3D scanning, material testing, non-destructive testing, ultrasonic thickness measurements and much, much more – all with the aim of assessing the object to form a valid conclusion on its composition.

2. Modelling and design

Next, object models can be created from the works detailed above. The most technical leg of the work, this is concerned with unlocking the mechanics and logistics that make the object work. In mechanical engineering, it is focused on redesigning the object from scratch based on the learnings found in the opening stage.

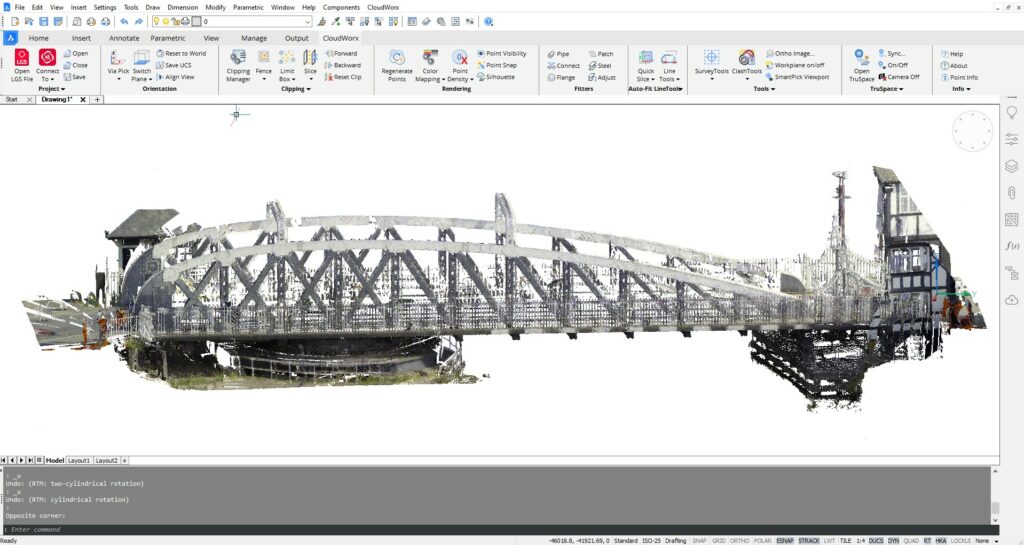

In combination with the CloudWorx, BricsCAD and Cyclone software, we have all the tools necessary to provide a full turnkey engineering surveying solution, including reverse engineering of existing equipment for design and installation of new structures, Fitness For Service Assessment, and re-design of damaged components.

3. Testing and review

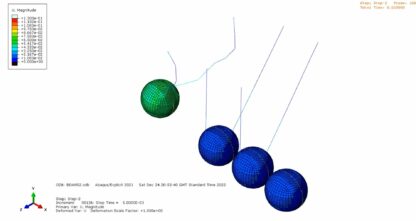

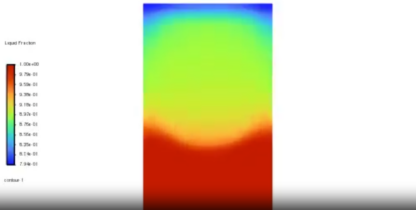

The model can then be tested in various scenarios to confirm that it is a realistic and accurate model of the original object, system or structure. The testing process takes a different shape depending on the industry, but in mechanical engineering, this will largely involve using computer-aided engineering tools to run simulation tests.

Once the testing has concluded, and the concept proven successful, the model can be used in the following legs of the engineering project.

Why would you want to reverse engineer an object?

Whether it’s rebuilding a bridge or analysing human DNA, professionals can find a world of learning by simply taking the object apart and putting it back together again. By breaking something down in order to understand it, one can then use the understanding to make informed decisions on the project.

Let’s take the oil industry as an example. You may find that some refineries contain outdated equipment, in dire need of repair or modification to ensure that it can remain in use. The problem may well be that because this equipment was built decades ago, the drawings have been lost. Without this design information it is very difficult to make clear decisions on the best route to safe modification – and that’s where reverse engineering comes in, it allows us to explore what already exists, and in doing so any vulnerabilities of the object are identified. It also helps industries bring more cost-effective products and equipment to their operations.

Reverse engineering with DOCAN

We have undertaken many projects that required reverse engineering of existing structures in order to develop, design and install new equipment. Advanced equipment, such as the Leica RTC360, P40 long range scanner, and Total Station allow for accurate scans of large areas in a short time, while the Leica Absolute Tracker and handheld scanners can be used for detailed scans on a smaller scale.

We offer a host of engineering consultancy services that you can browse by clicking the embedded link. Established in 2017, our team of professional engineers, designers and consultants bring together expertise, powerful technologies and a wealth of industry experience as a growing engineering consultancy in the UK that solves problems.

Contact us for more information about our services or pop us a message using our live chat system.