What is the difference between SolidWorks® and Solid Edge®?

Both SolidWorks® and Solid Edge® are similar in functionality, but which is the best CAD software?

Comparing the different features & functionality of each software.

Operating as an engineering consultancy, we use a variety of CAD software when helping our clients drive successful projects forward.

In fact, we think it’s necessary not to put all our eggs in one basket when it comes to the tools we use as having access to a range of industry-leading engineering software means that we can use the perfect technology for the job at hand. Often, this will also mean using a combination of a few to get the desired results and bring both time and cost efficiency up.

Now, for those who don’t have access to this kind of technology or simply don’t want to fork out for multiple subscriptions, you’ll want to make sure you’re getting a good all-rounder that can perform all of your desired functions.

When it comes to CAD software, there are many questions surrounding the differences between SolidWorks® and Solid Edge®. Both are similar in functionality, but which is best? In this blog, we’ll compare the key features and differences that we find between both to help you make an informed decision.

Quick links:

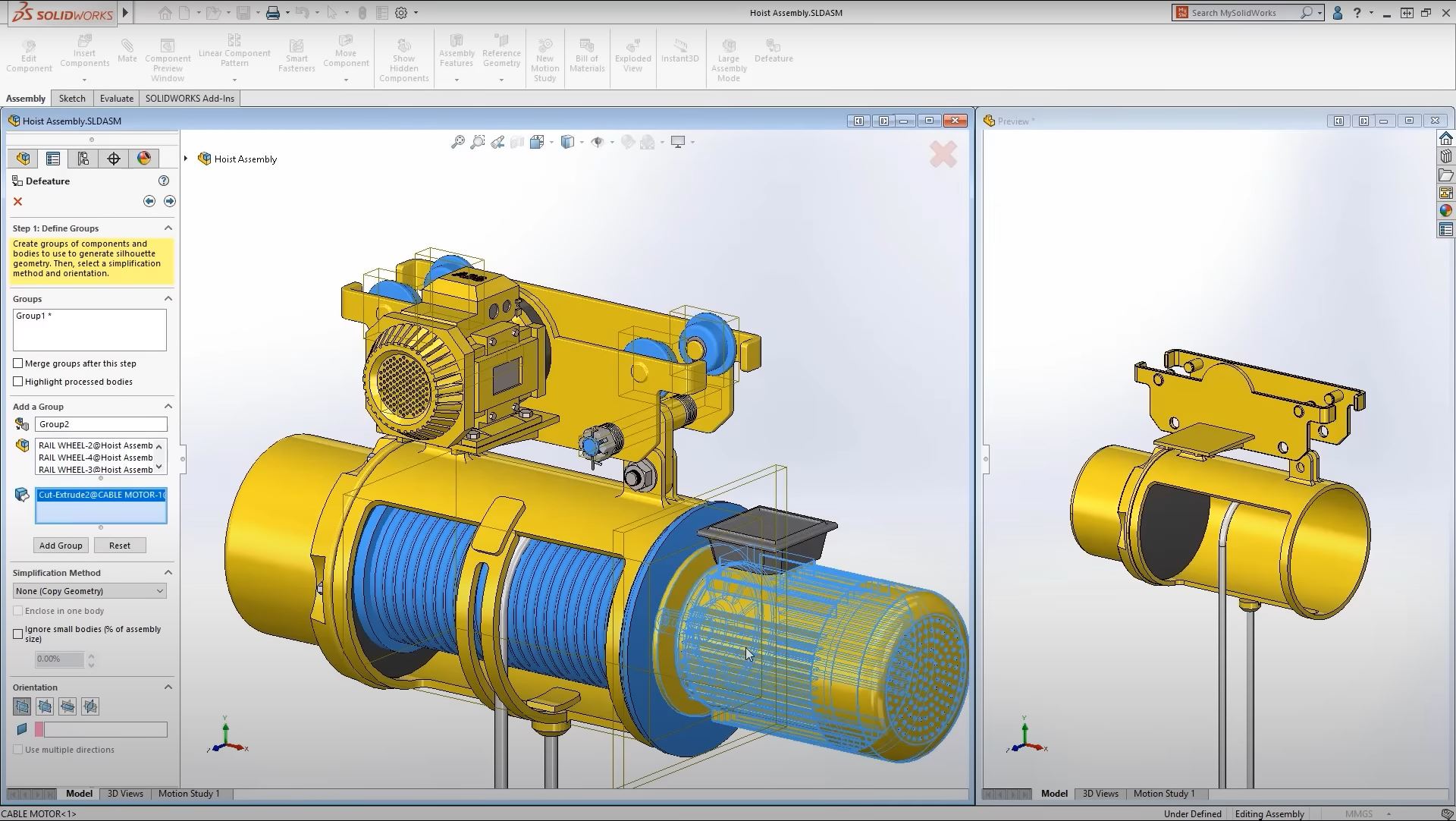

What is Solidworks®?

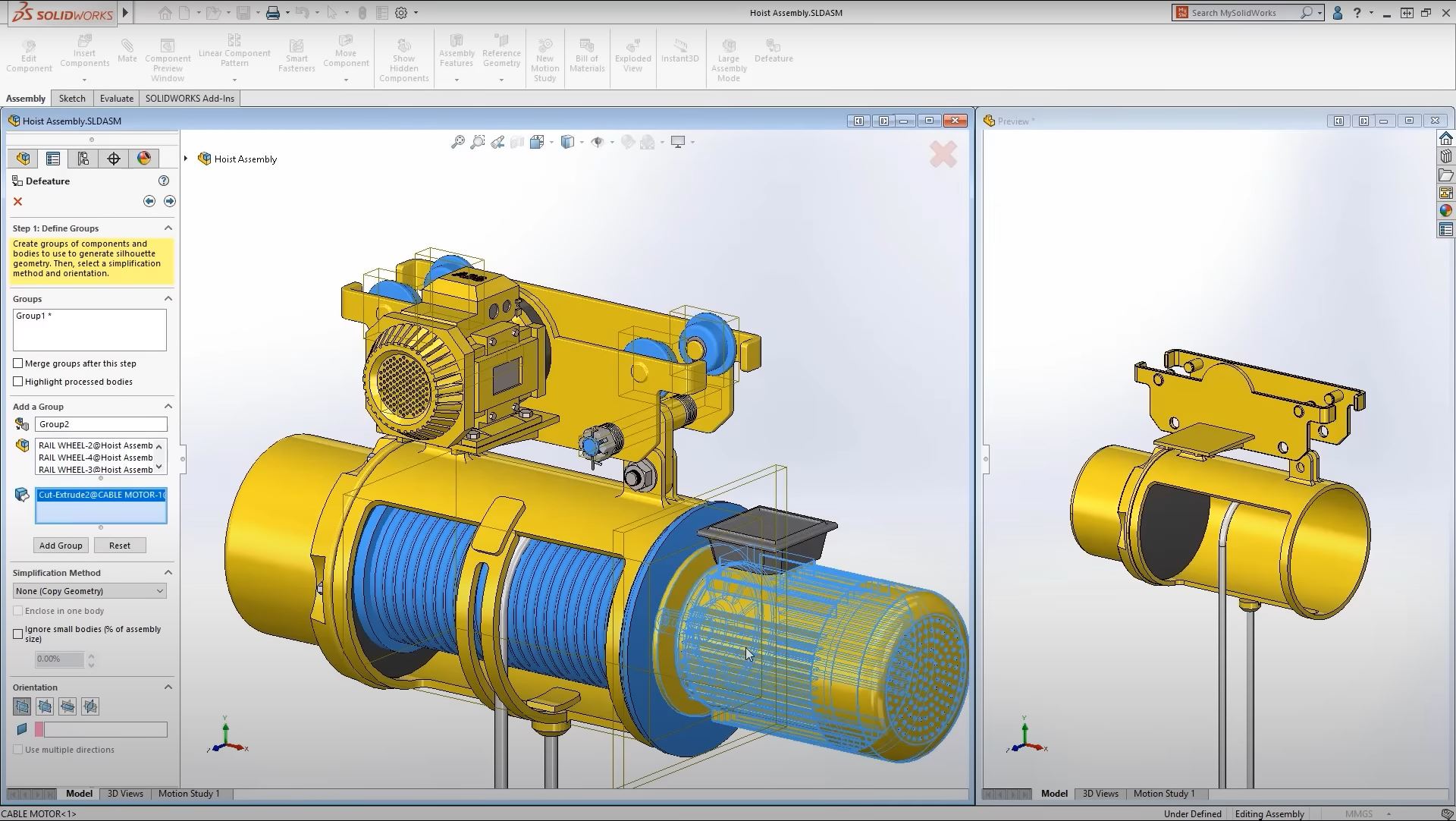

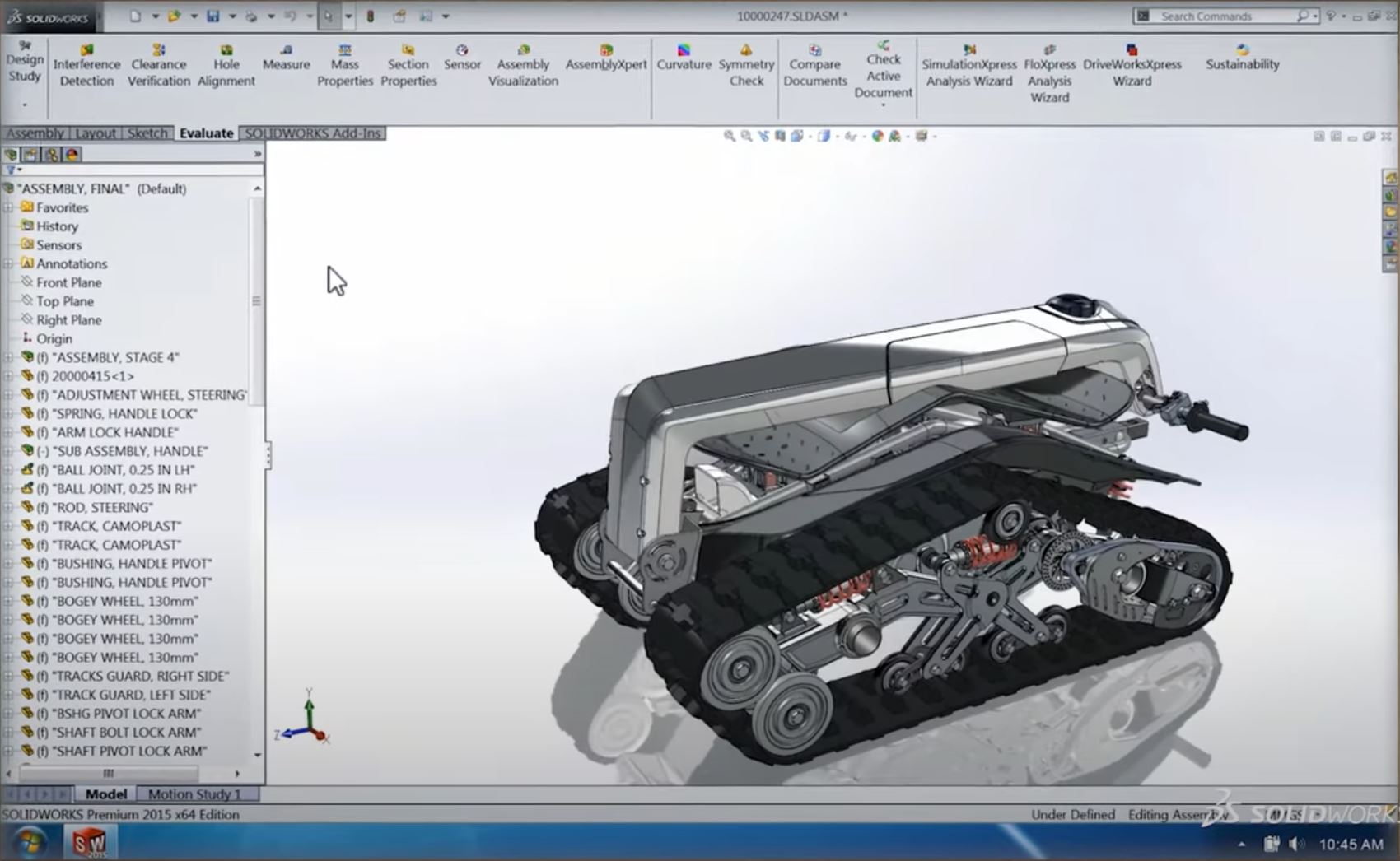

SolidWorks® is a leading Computer-Aided Design (CAD) software developed by Dassault Systemes, primarily used for designing and engineering parametric 3D models.

It’s no secret that SolidWorks® is one of the most popular programs on the market, due to its comprehensive suite of features that not only supports the creation of 3D drawings but enables the user to perform complex simulations and generate accurate technical drawings. What’s more, it supports built-in Finite Element Analysis (FEA) and Computer-Aided Manufacturing (CAM).

It’s a great all-rounder package which can support the entire product development process, making it versatile for both small and large projects across a variety of industries.

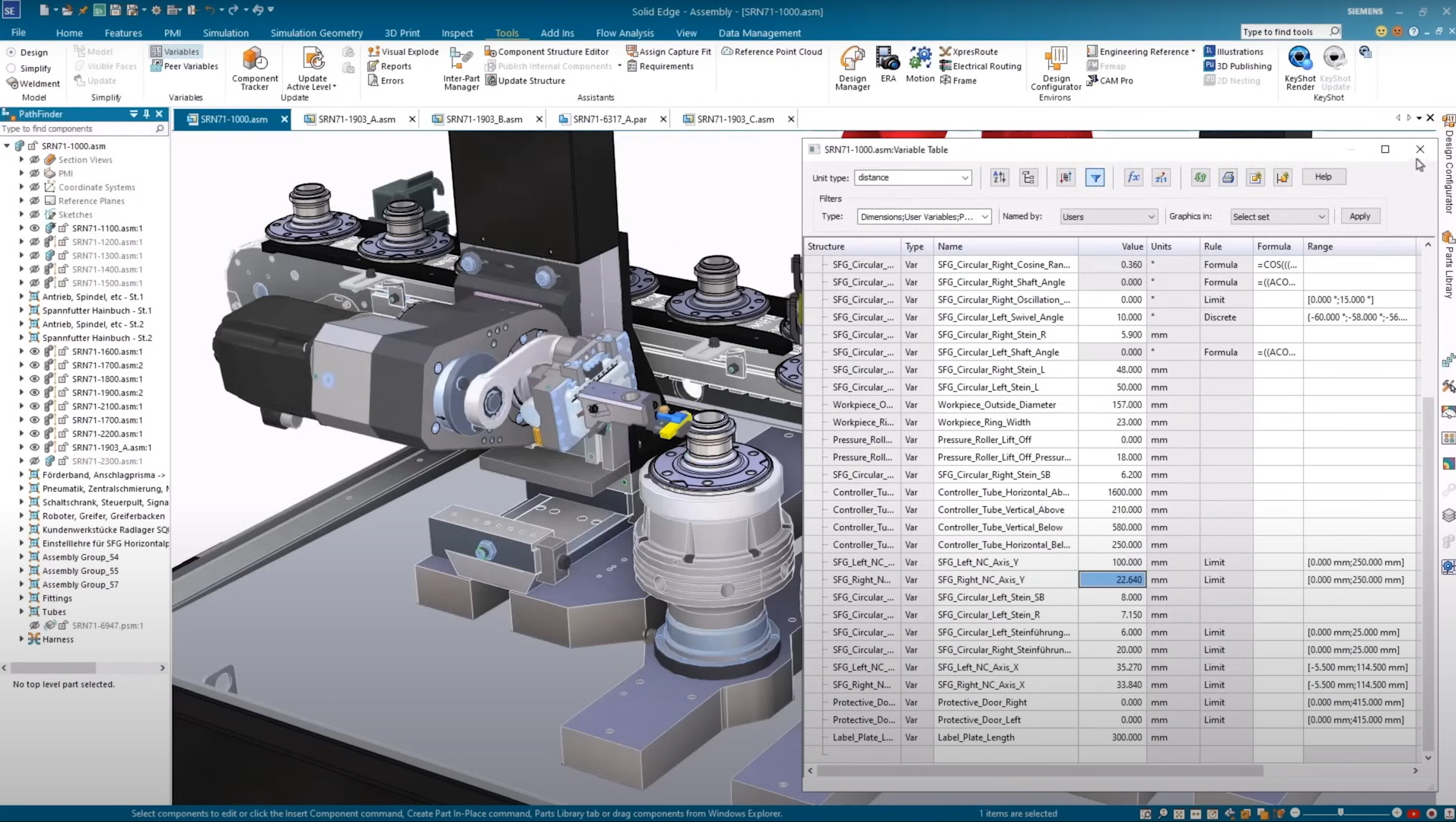

What is Solid Edge®?

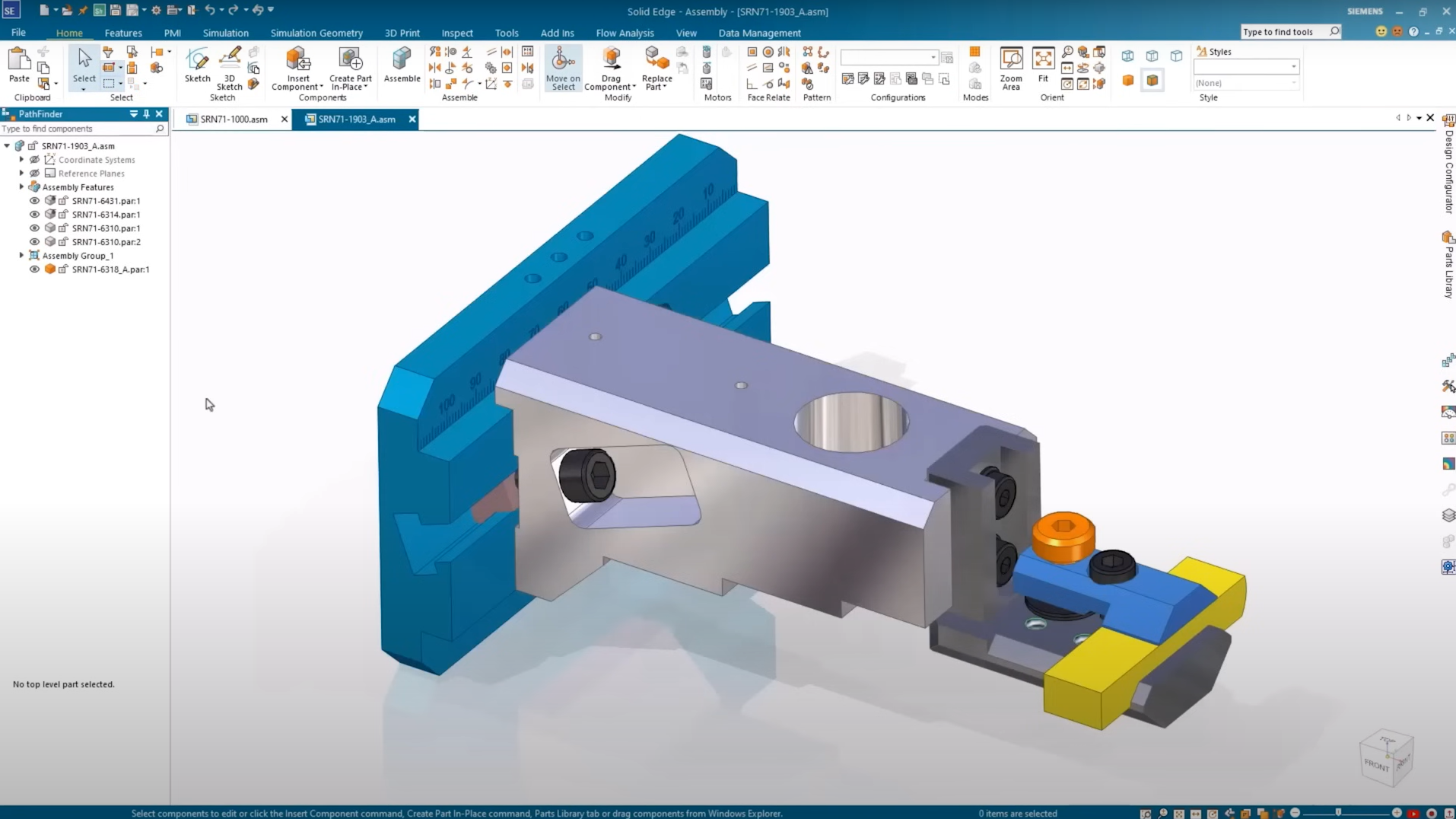

Similarly, Solid Edge® has been a key player in the CAD industry since the 1990s when it was developed by Siemens.

A powerful CAD software designed for creating and managing 3D models and assemblies, Solid Edge® is renowned for its advanced features such as generative modelling, electrical design and CAE (Computer-Aided Engineering).

What sets Solid Edge® apart is its speed and simplicity of direct modelling with the flexibility and control of parametric design. Essentially, this means we can quickly make changes to designs without the limitations typically associated with parametric modelling.

SolidWorks® vs Solid Edge®

Both SolidWorks® and Solid Edge® are popular choices for many reasons, but typically there will always be one or two things that will swing it one way or the other.

We’ve broken down the individual features and specs of each software to offer a fair comparison. It’s worth noting that we’re not biased towards any of these software as we use both for different reasons, but here’s everything we know about each of them.

Modelling techniques

The modelling capabilities of any CAD software are going to be a key driver when it comes to choosing the right one for you. Both SolidWorks® and Solid Edge® offer excellent modelling capabilities, but they do it differently.

SolidWorks® excels in its parametric design approach which allows users to define models based on parameters and relationships that can be modified easily, offering a more efficient way of creating detailed and precise models.

Solid Edge®, on the other hand, combines both direct and parametric modelling. Using this hybrid approach, you can easily make quick edits directly on the model without having to navigate through historic data all while being able to use parametric control when needed. This can help enhance flexibility and accelerate the design process, making it easier to handle design changes and iterations.

Both platforms also offer tools for feature-based and surface modelling.

The best choice for you will come down to whether you prioritise parametric control (SolidWorks®) or modelling speed and flexibility (Solid Edge®).

Simulation capabilities

Whether we’re designing a product, structure or component, simulation is a fundamental part of the process to ensure that the design not only looks the part but behaves the way we want it to. Ideally, we’ll do this within the CAD software itself rather than having to transfer data back and forth – thankfully, both SolidWorks® and Solid Edge® integrate powerful simulation tools within their environments.

SolidWorks Simulation Suite allows us to perform structural, thermal, fluid flow, and motion analyses. This is helpful for validating designs through FEA, optimising performance and identifying any potential issues early on.

Solid Edge® also has built-in simulation tools, powered by the Simcenter technology from Siemens. Again, these are capable of all types of analyses including structural, thermal and motion simulation.

We’d say both are very similar in their capabilities, but SolidWorks® might have a slight edge as it offers a more extensive simulation suite and can seamlessly integrate with other Dassault Systemes tools such as Abaqus.

Design tools and features

Each software has a suite of tools for not only creating and editing 3D models but also simulating and testing designs. Here’s a quick overview of some of their key capabilities:

SolidWorks®:

- Sheet metal design

- Welded structure design

- Piping & tubing

- Electrical design

- Printed circuit board design

- Assembly modelling

SolidEdge®:

- Sheet metal design

- Welded structure design

- Mould tooling

- Piping, tubing & electrical wiring

- Electrical routing and harness design

- Generative design

- Assembly modelling

As you can see, there isn’t much in it when you compare the two. Both have very similar capabilities but if we had to compare, SolidWorks®’ integrated suite for mechatronic systems and its broader toolset can be slightly more beneficial when working on complex, multidisciplinary projects.

System requirements

Whilst the basic functionality of both software is similar, they do have different system requirements.

Solid Edge® system requirements:

- Processor: 3.0 GHz or higher

- Operating System: Windows 10 (64-bit), Windows 11 (64-bit)

- Memory: 8 GB RAM for users in academia and 16 GB for commercial use

- Hard Disk Space: minimum of 7.5 GB

- Screen Resolution: 1920 x 1080 or higher

SolidWorks® system requirements:

- Processor: 3.3 GHz or higher

- Operating System: Windows 10 (64-bit) or Windows 11 (64-bit)

- Memory: 32GB or 64GB RAM

- Hard Disk Space: 20 GB

- Screen Resolution: 1920 x 1080 or higher

There’s no drastic difference between the minimum system requirements for each but SolidWorks® generally recommends higher specifications to get the most out of the software. However, this will depend on the complexity of the project you’re working on and the specific features you need.

User-friendliness

SolidWorks® is renowned for its intuitive interface, packed with tools and features to make it the powerful program that it is. Its interface is more traditional on the CAD front, so it’s ideal for those transitioning over. Whilst it’s designed to be user-friendly even for beginners, the sheer amount of tools may be somewhat overwhelming and it may take a while to navigate the software.

Solid Edge®, however, is arguably easier to use for beginners particularly those who aren’t familiar with CAD software. It’s more modern and streamlined so may be quicker for first-timers to get to grips with the basic functionality, yet it still packs in many advanced features.

That all being said, SolidWorks® offers a more extensive library of support and resources, with a larger community offering help. Solid Edge® has similar but their learning materials aren’t quite as in abundance.

Applications

As with most CAD software, both SolidWorks® and Solid Edge® can be used across a broad range of industries and applications. From large complex structures to smaller, more intricate components, they both offer a large toolset with a large degree of flexibility to effectively design, simulate and test models.

The best choice really depends on your specific industry and project requirements. SolidWorks® is typically used for more complex engineering projects and product developments. So if we’re working with a client in automotive or aerospace on product design, for example, this is typically the software we’d use.

Solid Edge®, on the other hand, is generally the preferred choice for machinery, equipment design and electronics, as its tools are more specific to manufacturing and engineering.

So, which is better? SolidWorks® or Solid Edge®?

As we’ve hopefully covered in detail there, both SolidWorks® and Sold Edge® have their pros and cons. The choice ultimately depends on your specific needs and priorities.

If you’re looking for CAD software with comprehensive simulation capabilities, extensive design tools and a highly intuitive interface, you may sway towards SolidWorks®. Whereas if you’re looking for fast and efficient design iterations with high modelling flexibility, Solid Edge® might be the most suitable tool.

Realistically, you don’t need to choose between SolidWorks® or Solid Edge® as there are many other alternatives. Here at DOCAN, we use various platforms including BricsCAD, AutoCAD and CADWorx. Circling back to our point at the very beginning, we always use the most suitable software for the job we’re working on.

If you don’t have the right CAD software for your project, this is where we can help. We help clients in areas where they lack the in-house skills and resources to overcome their engineering challenges. We offer direct access to a team of highly skilled professionals and industry-leading software, get in touch with us to find out how we can help you.

Enjoy this article? You might be interested in some of our others: