A guide to engineering pressure systems

An insight into what pressure systems are, how they are designed and how they work in engineering.

In engineering, systems are designed or updated within an operational environment to achieve their intended purpose or purposes. There are, of course, a whole variety of systems – and this particular article is going to focus on pressure systems in detail.

We will discuss what they are, how they are designed and how they work in engineering.

This article will cover:

- What is a pressure system?

- Pressure systems in engineering

- How DOCAN design for pressure

- The requirement of FFSA in pressure system engineering

- What is FFSA?

- How DOCAN can help

If you have a pressure system project you’re looking for expert help with, get in touch with DOCAN.

What is a pressure system?

If a system has been designed to create a pressure boundary to contain a fluid, it can be deemed a pressure system. Not to be confused with the weather system of the same name, pressure systems are all around us; be it a canned beverage in the local corner shop, the central heating system running through your home or, on the grandest of scales, the network of pipelines that transport oil and gas from the sea bed.

They share one distinctly common trait, they are all designed to contain fluid held at a pressure difference compared to the outside environment.

Pressure systems in engineering

All pipes carrying fluids experience losses of pressure caused by the flow’s turbulence and friction. Engineers face many challenges in designing pipe systems, including pressure loss, water hammer, air entrainment and the impacts of severe and sudden temperature changes. All of these factors are considered in the design and development of piping systems, from the structure through to the materials used, efficiency is at the forefront of all pressure system engineering.

The original ‘modern’ pressure systems revolved around the application of steam and its use in the industrial revolution of the 1800s. Those systems which were developed to harness the power of steam were a key part of the following industrial revolution. Now, pressure systems are prevalent in power generation, transport, manufacturing and many more sectors in varying capacities, whether it be through hydraulics or otherwise.

How DOCAN design for pressure

Here at DOCAN we have taken on projects across different applications of engineering pressure systems. We have covered traditional pressure vessels and piping applications, through to R&D projects where we serve our clients to guide the design process and verify the integrity of their new designs.

Do you want to read more about our work in this area? Click on the project link that interests you, below.

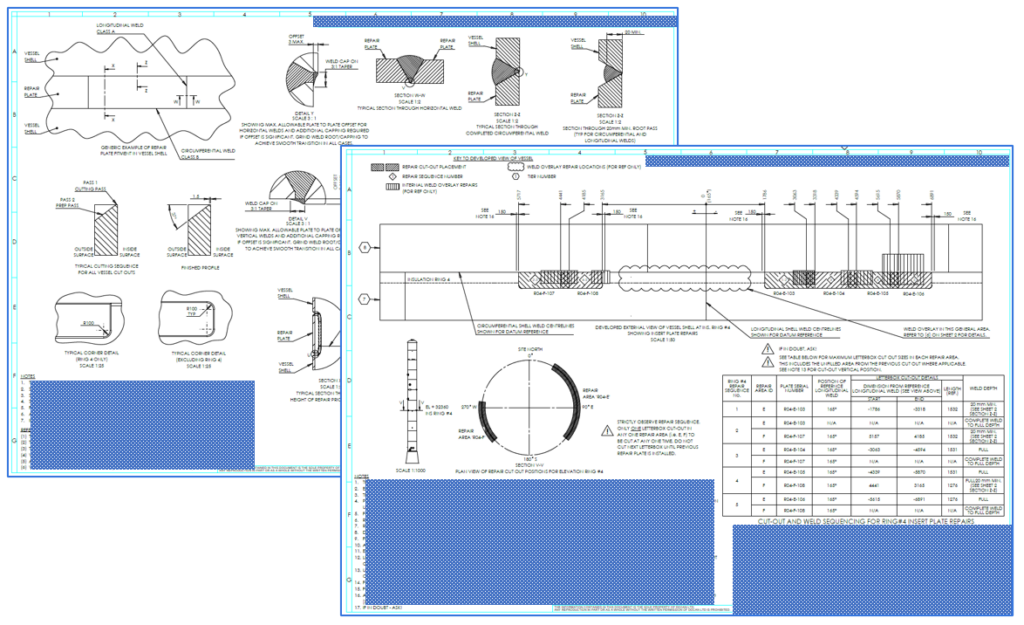

Repair Drawings for Pressure Vessel Defects

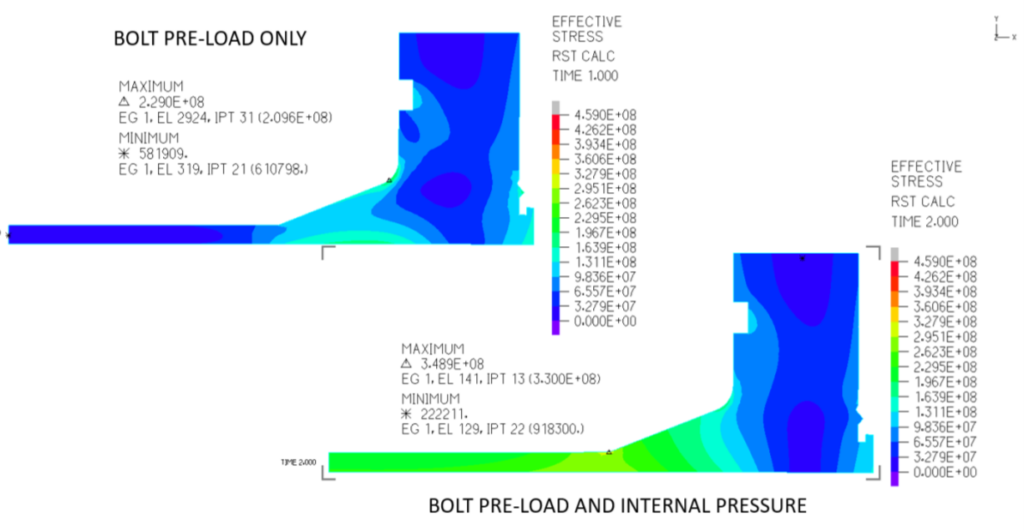

Structural Assessment for Pressure Vessel Defects

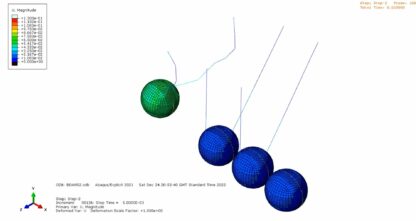

Piping Flow Slug Automation

The requirement of FFSA in pressure system engineering

Designing a new pressure system is one thing, but what about when an existing system isn’t working as it should be? Further, what if you have no way of knowing whether the system is or isn’t working to standard?

There’s where a Fitness for Service Assessment (or FFSA) comes in, and these assessments are becoming increasingly required.

When we consider that much of the United Kingdom’s Oil & Gas infrastructure has been around since the 1970s or earlier, we understand that these systems and their many components are becoming increasingly susceptible to damaging phenomena such as corrosion, fatigue, creep, and so on.

This work can involve elements of simulation, design and reverse engineering to achieve the project goals.

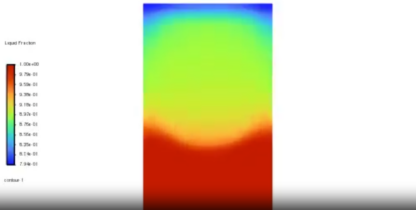

Why not read more in our project entry: Pipeline Defect Fitness For Service Analysis

What is FFSA?

FFSA covers the engineering methods by which we can assess the current structural integrity of equipment which has been subject to some damage and determine if it is safe to continue service for a defined period.

Sometimes referred to as Fitness for Purpose, these assessments help engineers to evaluate the structural integrity of a piping system overall, or individual components within the system, to determine whether it is suitable for its intended use.

How DOCAN can help

Piping and pressure systems fall well within our remit and expertise as an engineering consultancy. At DOCAN we have developed a team of engineers that can draw upon a number of years of experience in system engineering. We also have access to a wider network of associate engineers, giving us specialist insight when the project demands it.

As experts in the field, we are also positioned strongly to provide training on these sub-disciplines, primarily in relation to the application of the following process and pressure system software:

CAESAR II

PV Elite

Tank

PIPESTRESS

GT Strudl

To contact us directly in relation to a project or training enquiry you can use our contact form or call us on UK: +44(0)1606 212330 / USA: +1 888 874 0964